QUICK STOPPING – QUICKER INSTALL

Diesel World September 2009

Diesel technology has continued to evolve. Gone are the days of mechanical injection, and now a computer controls the cycles of high-pressure injectors down to the millisecond. Horsepower, torque and mileage numbers are up, while emissions emitted from the tailpipe and engine noise are down. It’s a brave new world from the days of IDI. With the engine improvements comes a new breed of aftermarket parts designed to take full advantage of the latest diesel powerplants.

Take, for example, exhaust brakes, which were designed to save brakes and make towing safer and easier. In the past, the installation included cutting and welding a flap apparatus into place. Getting all the plumbing and hardware set up was a solid day job for a professional, and could take the better portion of a weekend for the novice. If you own a 2004.5-to- 2009 Duramax pickup, though, you could get all of the benefits of an exhaust brake and then some without having to break out the welder. Actually, all you really need are basic hand tools.

The new SpeedBrake from Gale Banks Engineering is the latest in all-electronic exhaust brakes, with plug-and-play connections for a clean and simple installation, and no cutting or tapping required. It’s a feature-packed brake different from other exhaust brakes on the market. Not only does it increase the stopping power and extend the service life of brakes, its adjustable, maintenance-free and also capable of reading and cleaning the computer of codes.

Utilizing the factory VGT turbocharger on the Duramax, the SpeedBrake captures control of the varying vane position. Instead of closing a flap like traditional exhaust brakes, the SpeedBrake closes the vanes on the turbocharger to create backpressure. The SpeedBrake also takes charge of torque converter lockup and transmission gear selection to aid in the deceleration process. Meanwhile, the PowerPDA gives the driver feedback on important engine parameters and user-set on-screen alerts. (Please see note about the PowerPDA at the end of this article.)

We followed the install of the SpeedBrake into an ‘08 Chevy 25OOHD back at the Banks headquarters in Azusa, Calif. In less than 90 minutes, the truck was on the road with the SpeedBrake up and running. It was a painless process that produced some serious results when the truck was loaded with more than 10,000 pounds-worth of trailer and taken for a test-drive, all with barely getting the installer’s hands dirty.

While we have the scientific results in the sidebar (see below), we carried our own impressions of the SpeedBrake separate from strictly numbers. The thing that impressed us most about the SpeedBrake was the Speed Control feature. Think of speed control as cruise control of sorts, but instead of controlling acceleration, it controls deceleration.

Coming down Southern California’s Cajon Pass fully loaded and with the Speed Control set at 55, the SpeedBrake took advantage of the VGT turbo, closing the vanes at just the right amount needed to maintain the preset speed. It was as quiet as it was smooth, while the speedometer didn’t deviate from our desired cruising speed. Its smoothness is what really impressed us. Even on steep sections of the pass, the transmission didn’t have to downshift once the initial set speed was obtained.

The other shining point was the adjustability of the SpeedBrake from the PowerPDA. With the touch of a screen, the aggressiveness of the braking could be changed to low, medium or high. The high mode is slam-you-forward hard, as the transmission downshifts in a hurry to bring you to a quick halt. Under fairly light loads, it was almost too much. But throw some serious weight behind the truck, and the aggressiveness was welcomed when it came time to bringing the truck to a stop.

Along with the level settings, the other thing that stands out was the adjustability on how the SpeedBrake was activated. You have the option to allow the SpeedBrake to control itself and act like a traditional exhaust brake where it engages on deceleration, or you could activate it through the brake pedal.

The SpeedBrake is electronic and basically knows everything going on in the factory computer relevant to its operation. When you activate it through the brake pedal, you can push the pedal slightly and the SpeedBrake does its thing, creating backpressure and downshifting while enabling the truck to stop. We liked it enough that when the truck is empty, the SpeedBrake is set to activate via the pedal on medium strength, saving some wear on the brake pads in the process.

Overall, we think Banks Engineering has hit a homerun with the SpeedBrake. It’s a snap to install, is extremely effective and the adjustability allows the driver to tailor it to his or her preference. If you’re in the market for an exhaust brake for your 2004.5-to-2009 Chevrolet or GMC, it’s definitely worth consideration.

TECH

Testing the Banks Speedbrake

We hooked up a weighted trailer to the LMM-powered 2500HD, and brought the gross combined weight (GWC) to about 18,500 pounds. With trailer in tow, we headed to a desolate strip of road off California Hwy. 138 where we found a 1-mile strip with a 6.16-percent grade. We hooked up a weighted trailer to the LMM-powered 2500HD, and brought the gross combined weight (GWC) to about 18,500 pounds. With trailer in tow, we headed to a desolate strip of road off California Hwy. 138 where we found a 1-mile strip with a 6.16-percent grade. As the vehicle crested the top of the hill, speed was maintained at 55 mph, with drive as the selected gear. As needed to maintain a constant speed, the driver lifted off the accelerator pedal, which determines the beginning of the test. All tests were conducted with the Tow/Haul mode active. The foot brake was purposely not applied during descent, except to prevent unsafe speeds and runaway conditions. Speed was noted at the end of the run using a GPS-based data acquisition system. When the vehicle is in drive with the Tow/Haul mode active, the approach conditions to the test hill resulted in a fifth-gear selection. In stock condition, as the vehicle descended the hill, it immediately began to accelerate. With no application of the footbrake, the factory electronics allow for an upshift to sixth gear at 63 mph. This occurred 1,150 feet into the run. After traveling 2,400 feet, vehicle speed exceeded 70 mph.To maintain safety, the driver applied the foot brake and slowed the vehicle to 68 mph. At this point, the Tow/Haul mode strategy took over and shifted the transmission to fourth gear. Vehicle speed still increased and reached 69 mph by 3,400 feet. The foot brake was again applied and vehicle speed slowed to 65 mph. At this point, the Tow/Haul strategy allowed for a downshift to third gear. This allowed for vehicle speed to be maintained at about 65 mph for the duration of the run.1,000-foot speed = 62 mph  |

TECH

Understanding VGT Turbos and the SpeedBrake

| The latest LMM Duramax uses the Garrett VGT turbocharger. Variable Turbine Technology (VGT) is the latest in turbocharger technology, and variations are being used on the newest diesels. Because of the large displacement and requirements for air, engines like the 6.6L Duramax require large turbochargers. The bigger the turbo, the more exhaust pressure required to spool it, which creates a problem at lower engine speeds.

|

Note: The PowerPDA used for this article has now been upgraded to the new Banks iQ.

Visit Diesel World magazine online!

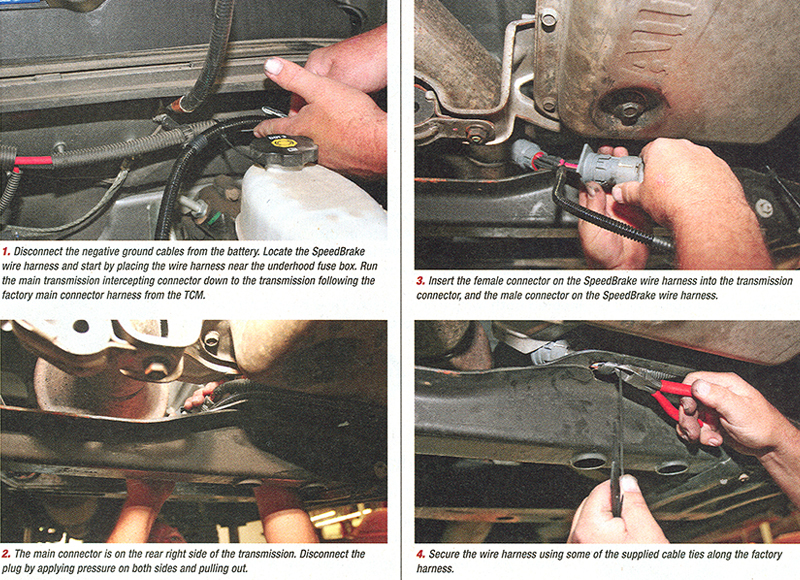

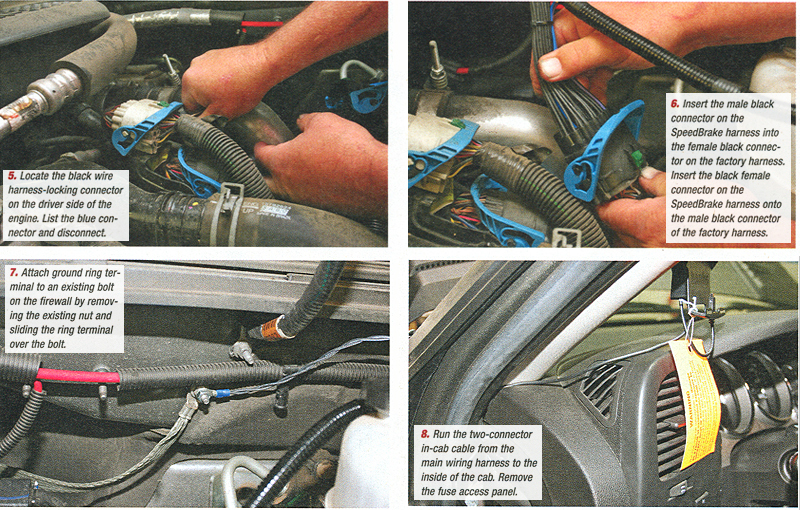

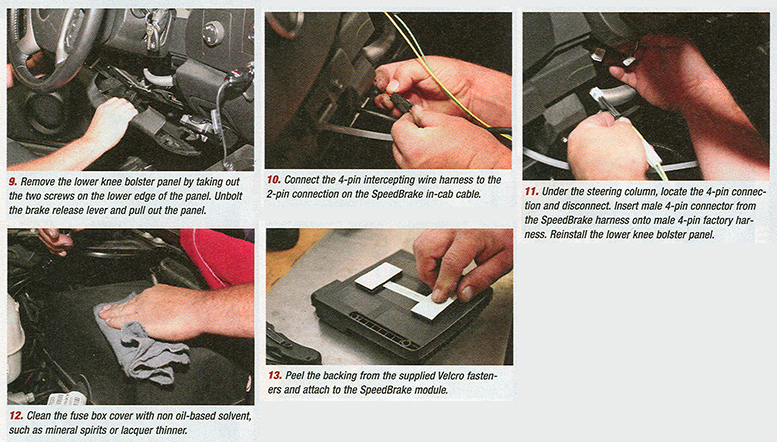

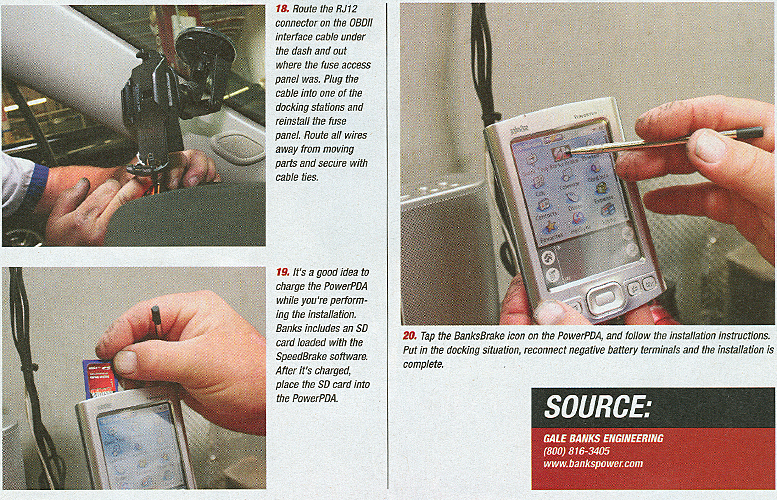

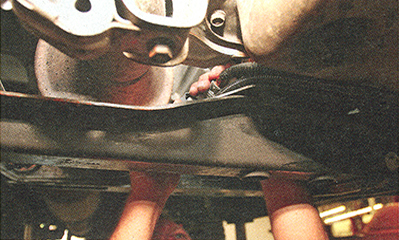

Disconnect the negative ground cables from the battery. Locate the SpeedBrake wire harness and start by placing the wire harness near the underhood fuse box. Run the main transmission intercepting connector down to the transmission following the factory main connector harness from the TCM.

The main connector is on the rear right side of the transmission. Disconnect the plug by applying pressure on both sides and pulling out.

Insert the female connector on the SpeedBrake wire harness into the transmission connection, and the male connector on the SpeedBrake wire harness.

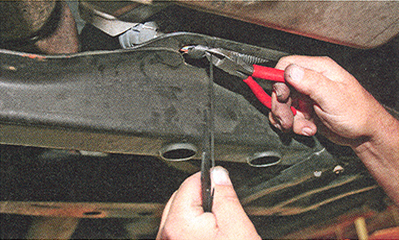

Secure the wire harness using some of the supplied cable ties along the factory harness.

AVGT turbo has small vanes connected to a actuator that can be moved to direct exhaust flow onto the turbine blades. The vanes are constantly moving open closed based on engine speeds. Vanes on VGT turbochargers aren’t like an old on/off switch; they can be fully open, fully closed, or positioned anywhere in between.At lower engine speeds, the vanes are closed, or close to it, which creates a narrow passage, accelerating the exhaust gas and directing them as they hit the blades of the turbine. As RPMs rise, more exhaust gas is generated, and the vanes begin to open up now that the engine is producing enough exhaust gas to spool the turbo. The result is the characteristics of a smaller turbo at lower engine speeds with enough flow to support the demands of larger, more powerful engines. A computer that takes in data from the sensors, and adjusts the vanes accordingly, controls the actuator that closes and opens the vanes on a VGT engine.

AVGT turbo has small vanes connected to a actuator that can be moved to direct exhaust flow onto the turbine blades. The vanes are constantly moving open closed based on engine speeds. Vanes on VGT turbochargers aren’t like an old on/off switch; they can be fully open, fully closed, or positioned anywhere in between.At lower engine speeds, the vanes are closed, or close to it, which creates a narrow passage, accelerating the exhaust gas and directing them as they hit the blades of the turbine. As RPMs rise, more exhaust gas is generated, and the vanes begin to open up now that the engine is producing enough exhaust gas to spool the turbo. The result is the characteristics of a smaller turbo at lower engine speeds with enough flow to support the demands of larger, more powerful engines. A computer that takes in data from the sensors, and adjusts the vanes accordingly, controls the actuator that closes and opens the vanes on a VGT engine. Think about a traditional exhaust brake in its simplest form. A flap is basically in the exhaust stream. When the truck needs to decelerate, the flap closes and the backpressure bottlenecks the exhaust system, which in turn builds pressure upstream from the brake. The pressure acts negative torque, slowing the engine down for a braking effect.Because a VGT turbocharger has vanes open and closed by a computer-controlled actuator, they can move at any time when given the command. Rather than have a flap, the SpeedBrake shuts the vanes on deceleration, essentially creating the same effect as a flap placed in the exhaust stream. Because it do it through computer manipulation, the system can be controlled with a module and a plug rather than having to weld in an actuated flap.

Think about a traditional exhaust brake in its simplest form. A flap is basically in the exhaust stream. When the truck needs to decelerate, the flap closes and the backpressure bottlenecks the exhaust system, which in turn builds pressure upstream from the brake. The pressure acts negative torque, slowing the engine down for a braking effect.Because a VGT turbocharger has vanes open and closed by a computer-controlled actuator, they can move at any time when given the command. Rather than have a flap, the SpeedBrake shuts the vanes on deceleration, essentially creating the same effect as a flap placed in the exhaust stream. Because it do it through computer manipulation, the system can be controlled with a module and a plug rather than having to weld in an actuated flap.