Preventing an Expensive Problem

“I think the first time we noticed the RAM 6.7L grid heater failure was four or five years ago,” recalls Bryan Banghart of Banghart Diesel & Performance in Wahoo, Nebraska. “RAM owners would come in for random intake heater codes. I think it’s a P2609, if I remember correctly. We’d grab hold of the grid heater stud where the wire attaches to see if it was loose. We’d pull on it, and we could tell that the nut was loose and burned. Back then, the first few that we ran into, we’d replace the grid heater with another stock unit and send them on their way. But I’d always wonder, ‘Did we fix the issue, or just defer the failure to another day?”‘

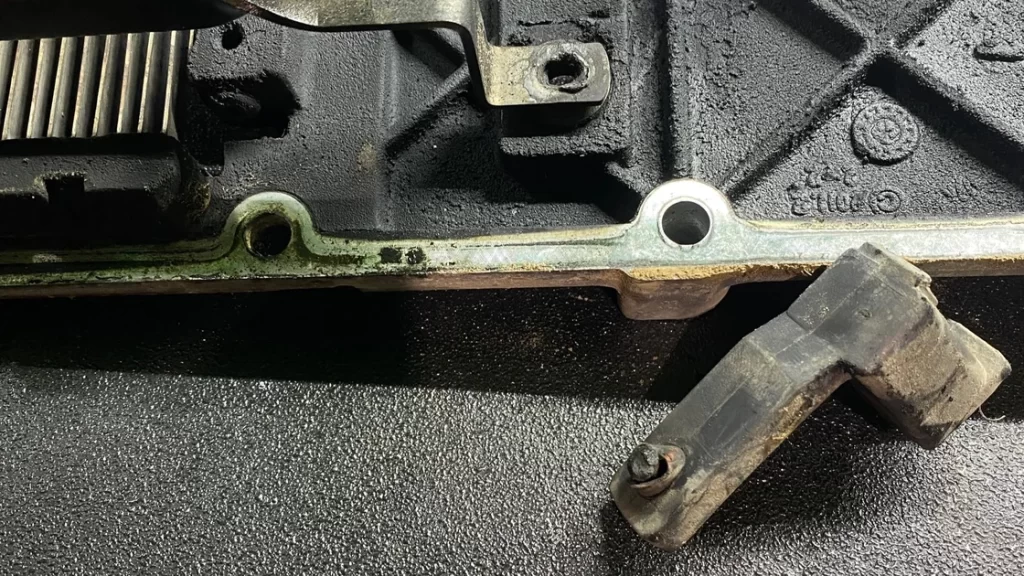

“We had a couple of them that developed a knock that you couldn’t hear at idle, but when you’d rev it up, you could hear it. We’d check the grid heater wire, and it would be loose. We’d pull the intake plate off, and the nut is gone. We’d pull the head, and generally, the bolt is on top of the number 6 piston. Most of them were pretty bad. We’d have to pull the piston. One of them needed an engine overhaul because the nut got over on the side of the piston and damaged the cylinder wall. There were a few of them where we caught it right away and were able to pull the nut out of the top of the piston, clean it up, and the customer was comfortable running it.”

“I think the factory intake plate fails due to the amount of current the bolt transfers over the strap to the grid heater element. It appears to be a combination of heat cycles and engine harmonics that causes the nut to loosen. When it gets loose enough, it starts to arc between the strap and the stud, and then it burns it out. Eventually, the nut falls off. It’s a fairly easy fix early on. You can save yourself from spending $10,000-$20,000 on an engine. It’s less than $1,000 for the Monster-Ram, and it will take you three or four hours to install. That’s peace of mind compared to having the nut fall into the cylinder and the engine goes down in the middle of who knows where. Now you have to get your truck to a shop and rebuild the engine.”

Bryan is no novice when it comes to Cummins engines. He graduated in 2003 with a degree in applied science in diesel truck technology. “The focus was on heavy-duty trucks, but I was more interested in something smaller and more technical, so I got a job working for a fuel injection company. That’s where I learned about Banks products. I had so many people calling me, wanting work done to their trucks, that I decided to make it my full-time job. That turned into a 15,000-square-foot, nine-bay service center known today as Banghard Diesel Performance.”

Primarily RAM 5.9L and 6.7L owners, Bryan’s customers include racers who compete in the Outlaw Diesel Super Series (ODSS) series. Bryan himself has been involved in truck pulling since 2003. What was once a daily driver that transported him to and from trade school, his 1992 RAM now pulls in the 3.0 limited pro diesel truck class. (3.0 refers to the maximum turbo size allowable in inches.)

“At the end of the day, it’s a bad idea to put a bolt and nut in two places in the intake where you can’t see or inspect them,” Bryan says with a chuckle. “I think it’s just a matter of time and heat cycles. As these RAMs get older, I think you’re going to start running into this issue more often. I’m thankful that Banks offers a cost-effective fix in the Monster-Ram that also improves performance.”

If you’re in the Omaha area and need a Monster-Ram or other Banks performance parts installed, keep Bryan and his crew at Banghart at the top of your list.

Banghart Diesel Performance

1740 N Chestnut St

Wahoo, NE 68066

(402) 277-7374