Supporting 1,000 lb-ft of torque | BANKS BUILT 11

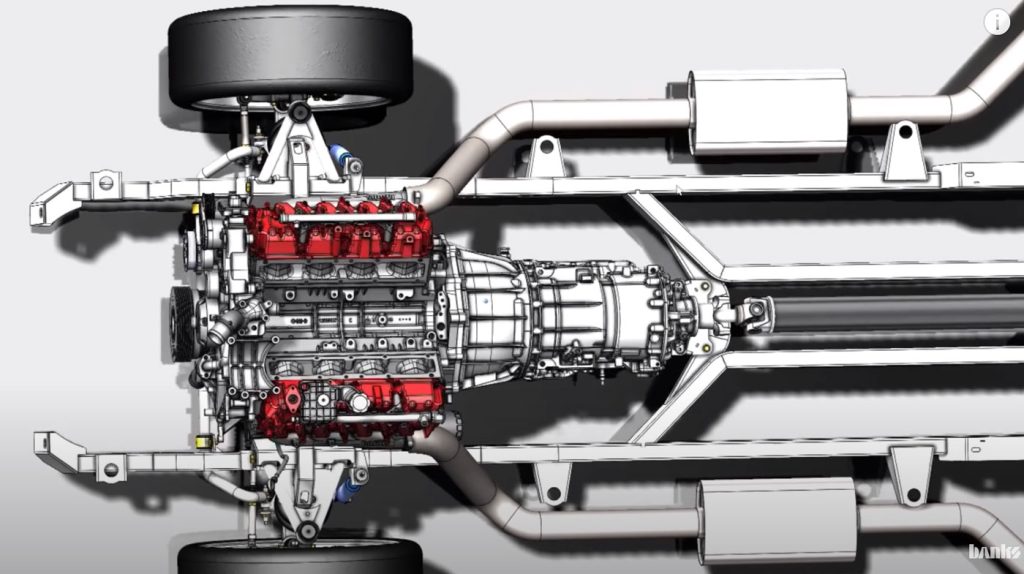

Jay and Eric are back at Roadster Shop to check on the chassis built for supporting 1,000 lb-ft of torque. High torque is what tears apart a chassis and that’s why we worked with the experts. See what they did to reinforce the chassis.

00:00 Intro

00:59 Duramax L5P fitment

01:37 Wet sump vs dry sump

02:24 Front sway bar

02:59 Exhaust manifold clearance

03:24 Transmission and exhaust

04:17 Chassis reinforcement

05:53 Watts link

08:49 Tires sizes

11:06 Supercharger height

13:28 Next episode preview

Watch Roadster Shop engineer a custom Spec Series chassis for LokJaw, our supercharged Duramax-powered ’66 Chevy big-window long bed. Not only does the chassis have to accommodate a much larger engine than a typical C20 pickup, but it must also support over 1,000 lb-ft of torque. Not to mention it has to lay flat on the ground. In other words, they have to create a Swiss Army knife.

The Duramax is the largest engine the team has dropped into one of these chassis. “Torque breaks welds and diesel trucks are all about torque,” explained Jay. Supporting this much torque takes geometry and design.

Catch up on epsiode 10 of Banks Built and keep watching to see the chassis reveal.