Test fit of lower bed assembly | BANKS BUILT 36

The guys head back up to Empire Fabrication to test fit the lower bed assembly for our supercharged Duramax diesel-powered ’67 Chevy C20 pickup. The assembly is made of five pieces that will support the bedsides. If they don’t fit, we’ll be going to the SEMA show in November with no truck bed. Call this part—critical. As they bolt the complicated assembly together, they realize a couple of measurements were wrong. Here’s how they fixed it.

00:00 Intro

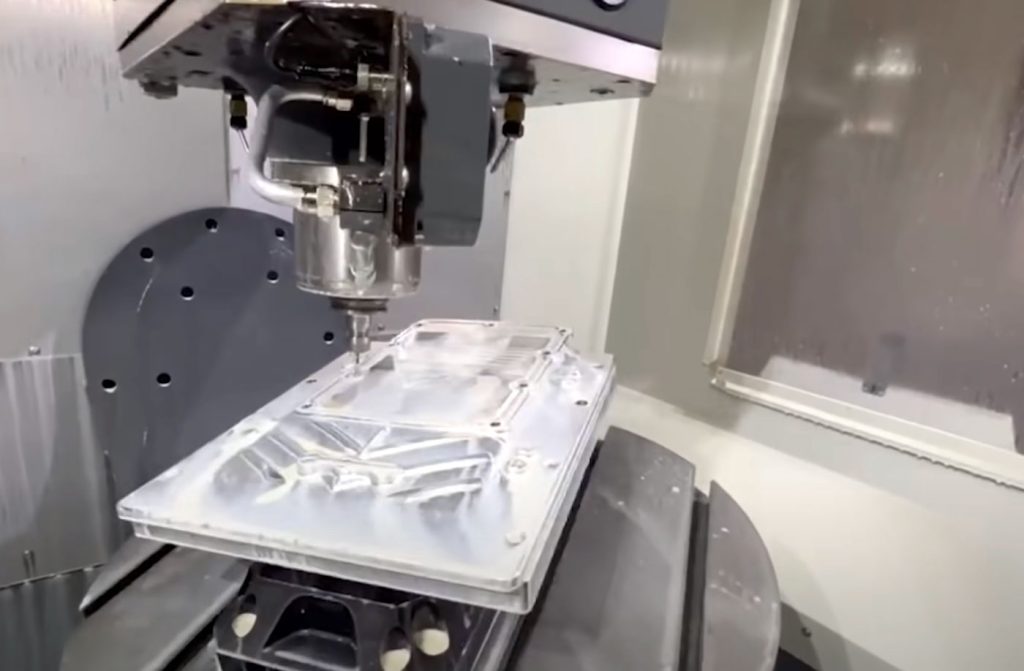

01:00 Billet intake manifold

02:53 Bed support plan

05:02 Bed support installation

Over at Kibbetech, Ryan shows off the custom intake manifold they machined out. They used the five-axis machine to get it just right. It’s going to look sweet on LokJaw.

Jumping back to Empire, the team finishes the bed support test fit so they can start bolting everything down. This is after a critical panic because the bolts were not fitting the holes. Lots of creative solutions were made on the fly during this episode. After proving why test fitting is important, the team goes home for the night.

Next week, take a tour inside Whipple Superchargers, meet Dustin Whipple, and watch the production of our Gen 5 blower.