P2609 and P0542 Codes | Avoid RAM 6.7L Grid Heater Failure With the Banks Monster-Ram

Understanding the RAM grid heater problem

RAM grid heater failure is a known issue that can lead to catastrophic damage if not addressed. Read on to learn how the Banks Monster-Ram can prevent it. Over time, a bolt in the 2007-2024 RAM 6.7L Cummins stock grid heater deteriorates, falls into the intake runner, and thanks to gravity, makes its way into cylinder #6. In many cases, this results in severe piston, valve, and head damage or total engine failure. Although the issue has existed for years, many mechanics either aren’t aware of the problem or do not fully disassemble the engine to properly diagnose it. They simply replace the engine. Therefore, the problem persists. The malfunction appears to affect all year ranges of the 6.7L Cummins engine, regardless of mileage or geographic region, or climate.

How to identify the problem

RAM owners are typically alerted by a check engine light. Using an OBD scan tool, P2609 and/or P0542 diagnostic trouble codes are often present.

A P2609 code indicates an issue with the intake air heater system voltage or performance and often means the grid heater bolt is failing and has lost its ability to conduct current.

Similarly, a P0542 code indicates that the truck’s powertrain control module (PCM) has found that the input voltage reading from the intake air heater circuit is not normal when compared with the manufacturer’s guidelines. This could be triggered by harness connectors corroded or improperly seated, an open circuit, or high resistance present in the heater relay. In some cases, it might take up to three drive cycle failures before the Check Engine lamp comes on. Both P2609 and P0542 are reasons for concern.

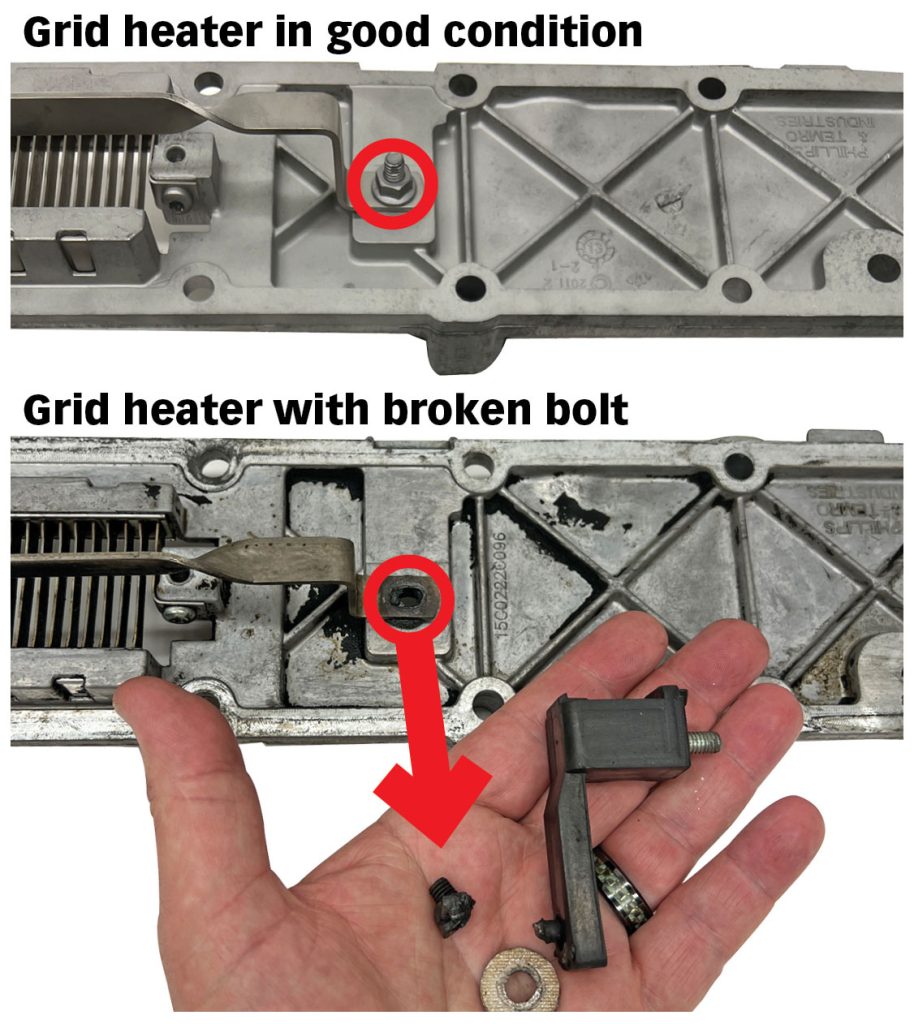

Looking at the bottom of the factory grid heater, you’ll see a bolt and nut. The top of the bolt is connected to the +12v lead which energizes the grid heater. Current passes through the bolt, (a stud, technically) to the metal strip that travels to the grid heater element. Over time, this stud and nut assembly, along with the steel post, have been known to melt and fall off into the intake runner, ultimately making their way down to cylinder #6.

Below, you’ll see the hole where the nut and bolt used to be. Unfortunately, this RAM owner was unlucky. The stud bounced around in cylinder #6, resulting in extensive piston, valve, and head damage.

In the photo below, you’ll see two air intake grid heaters flipped upside down in order to get a better view of the problem. Notice the new grid heater on top compared to one that suffered from bolt failure.

As described in the video below, air intake heater failure can be detected by jiggling the +12v lead that connects to the top of the grid heater. If the plastic assembly rocks back and forth, it’s likely that the bolt has sheared off and is rolling around the intake manifold or worse.

Some RAM owners have gotten lucky using the jiggle test to catch the issue before the bolt had broken free. If you feel any significant movement in the plastic post, do not drive the truck. Tow it to your local mechanic for proper inspection as Randy did in the video above. The +12V post is shown below. It’s located next to the fuel rail.

The result of a broken grid heater bolt is often engine failure. Seen below is a piston after the bolt ended up in cylinder #6. The piston slapped the bolt into the head and valves until the engine failed. Unfortunately, the gouges in the head were below the minimum deck height and could not be machined back to stock tolerances. The owner was forced to purchase a new piston, head, and valves. With labor, the bill exceeded $10,000. Dozens of other RAM owners haven’t been as lucky, having to purchase new engines at over $30,000.

RAM dealers can’t help, here’s why

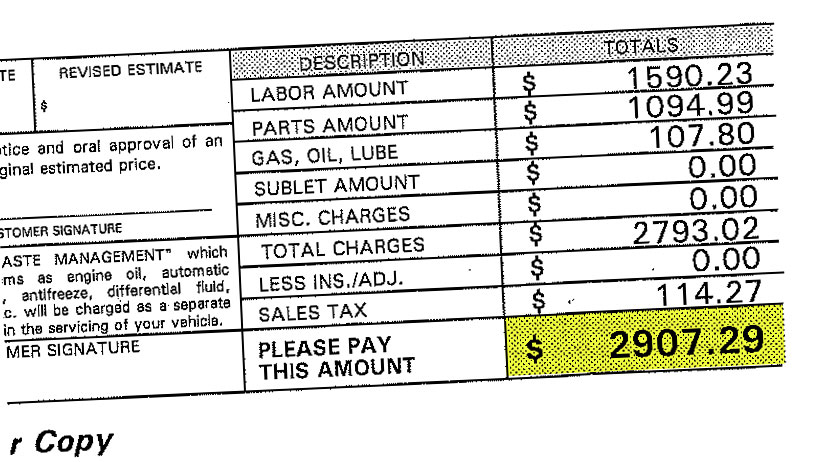

Dodge RAM service centers can only offer certified RAM replacement parts. These are the same parts that have already proven to be failure-prone. To make matters worse, parts and labor are typically just shy of $3,000.

The solution is Banks Monster-Ram Intake Elbow

The Banks Monster-Ram intake elbow was engineered to provide performance gains in air mass flow. Not only is the system superior to the stock unit but it handily beat all competitors. An impressive 88.3% gain in mass flow results in better throttle response that you can feel as well as improved fuel economy.

All other intake elbows had gashes or dents in them to allow the stock fuel line to pass over. To make massive improvements in air density, Banks engineers designed a proprietary #1 fuel line that hops over the Monster-Ram, allowing for unobstructed airflow. The next gain in airflow was achieved by replacing the stock, restrictive, grid heater with a billet high-flow intake plate. Cold starts are aided by a coil heater that sits vertically within the Monster-Ram’s aluminum casting.

When designing the system, the engineers hadn’t considered the growing concern over the factory grid heater’s predisposition to fail. It wasn’t until ProTech Diesel Centre in Kamloops, British Colombia called to praise Banks for solving the dreaded bolt failure issue that Banks engineers realized they’d killed two birds with one stone.

One look and you’ll see just how free-flowing the Monster-Ram is compared to the factory intake elbow.

As usual, Banks delivered an outstanding product. The catastrophic grid heater GONE. Now I can rest easy. Definitely feel a difference in throttle response, feels like it has more power and turbo lag GONE.

⭐⭐⭐⭐⭐ – Brandon O., Sonora, CA

Stop RAM Grid Heater Failure With the Right Upgrade

The Monster-Ram is the go-to for RAM owners aiming to improve performance, fuel economy, and prevent grid heater failure. And best of all, it’s 50-state emissions compliant. Upgrading to the Monster-Ram is the most effective way to eliminate the risk of RAM grid heater failure permanently.

Now available for chassis cabs!

Related Sources

Banks Monster-Ram Intake System

Banks iDash SuperGauge

RAM Tech Tips