Diesel Fuel – Part 2

Gas-to-liquid (GTL) diesel fuels are making their way into the fuel supply. One company, Rentech, has developed a fuel that will work in even the most finicky diesel engines…and may have some applications in racing.

In many ways, the production of biodiesel in the USA is still the equivalent of making moonshine. That’s one reason why major manufacturers are worried about what it might do to the engines we now operate.

Our Story So Far: Last week, we pointed out that there are wide variations in fuel quality throughout North America, and we took a look at some of the fuels that are now being developed, and how they compliment and/or complicate the fuel picture for racers and diesel owners alike. Some of the fuels now available include gas-to-liquid (GTL) fuels and of course, biodiesel.

Biodiesel can be exceptionally clean, and offers a beneficial level of lubricity, yet biodiesel is also one of the fuels manufacturers are most concerned about. Biodiesel, usually made from soy oil feedstock, is hard on engine lubricants, tending to get into the sump and corrode bearings. And there are concerns about wide variations in quality. These variations are based on feedstock characteristics, but also manufacturing processes.

“Biodiesel producers, a lot of them, are producing the automotive equivalent of moonshine,” pointed out Gale Banks, speaking at a panel discussion October 21 at the Petersen Automotive Museum. In addition to our own Gale Banks, the panel discussion included speakers from Audi, Green Car Journal, Rentech Fuels, Argonne National laboratory, Global Green USA, and the US Coalition for Advanced Diesel Cars.

“In an AQMD meeting perhaps a year and a half ago, it was revealed that there are a number of biodiesel producers in the states, and very few of them comply with the standard,” Banks said. “Out of 50 or so, maybe two or three of them complied. Only a few had a fuel you could count on being what it should be, so that once you’d engineered your engine, you knew this was a consistent fuel type.”

As a result, manufacturers have not been comfortable with the idea of burning pure biodiesel, or B100. The newest engines from Ford and GM tolerate blends up to 20% biodiesel, while VW and Audi will void warranties if fuels containing more than 5% biodiesel are used.

That was why we were surprised to see Audi participating in a program to demonstrate an alternative fuel developed by a company called Rentech. Green Car Journal, using Audi A3 cars, recently drove 1000 miles on Rentech’s trademarked synthetic diesel fuel, called RenDiesel. The fuel is produced by a GTL process, which results in higher cetane levels and very low sulfur, with very low soot levels. According to Ron Cogan, Editor and Publisher of Green Car Journal, over the 1000-mile journey, the fuel appeared to be completely compatible with the Audi A3 2.0L turbo diesel engine. Unlike biodiesel, the RenDiesel seemed to be suitable for the engine without blending with standard pump ultra-low-sulfur diesel.

Ron Cogan announced that during their 1000-mile test of Rentech’s fuel, “there was no difference in power, no hesitation of any kind. There was no indication that we were driving on anything other than pump ultra-low-sulfur diesel.”

The A3 was not modified in any way. “It came straight out of the press test fleet,” Cogan told us. We were told the fuel is clear, and it doesn’t look or smell like regular diesel, but perhaps a bit like paraffin. If you spill it, it evaporates much more quickly than the #2 diesel we are used to, without really leaving an oily spot.

During their trip driving south from Eureka, California, the Green Car Journal team tracked mileage and saw numbers ranging from 39.0 to 43.7 mpg. The EPA estimate for the Audi A3 diesel is 42 mpg highway.

The RenDiesel fuel offers some interesting possibilities for the future, and a strange contradiction with regard to Audi. The company is building a plant in Rialto, California, to produce approximately 640 barrels per day of renewable synthetic fuels, called RenDiesel, and approximately 35 MW of renewable electric power (RenPowerTM). Interestingly enough, the feedstock will include urban green waste diverted from landfills. That is, it will be a form of biodiesel, based on a yardwaste-to-fuel concept. Though it has a bio origin, in this case, the fuel will conform to ASTM D975 spec for ultra-low-sulfur diesel fuel, so it will be a biodiesel with no risk of oil dilution or manufacturing consistency.

What’s the difference? It’s in the process.

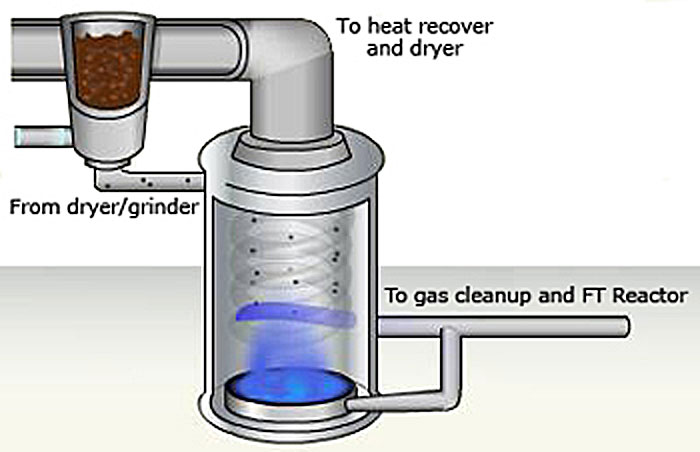

A fuel expert at Renfuel explained: “You can take any bio mass, any carbon source, gasify it, run it through the Fischer-Tropsch process, and then hydroprocess that material into diesel and jet fuel. You can then also take fats and oils, hydroprocess those, and make essentially the same fuels. So even though they came from two totally different sources by these different mechanisms, they make the same paraffinic hydrocarbon products. For all intents and purposes, you can’t tell them apart.”

In other words, because the RenDiesel is made using Rentech’s GTL process, the source of the feedstock really does not matter. The fuel is just like standard ULSD, but cleaner and with higher cetane ratings. The emissions produced by combustion of RenDiesel are lower in particulate matter (PM), nitrogen oxides (NOx), sulfur oxides (SOx) and carbon dioxide (CO²), compared to petroleum-based fuels. In addition, RenDiesel produces fewer emissions of volatile organic compounds (VOC) than ethanol or traditional clean diesel and has the potential to be twice as fuel-efficient as a car running on ethanol. Additives are used to bring the fuel up to ASTM spec for characteristics like lubricity. Audi knew the A3 would tolerate the GTL fuel well, because they run their R15 race car on something very similar.

We won’t see RenDiesel on the market immediately—most of the production will go to fleets—but the company has indicated it will make some of the fuel available to Gale Banks Engineering for testing and racing purposes. “It sounds like we need to get our fuel in the Banks race cars,” said Hunt Ramsbottom, CEO and Director of Rentech. Banks agreed. “I’ve been kind of dragging my feet testing alternate fuel types, he said. “ Now I’m all over it.”

That would mean you can expect some information and data coming from the Banks dyno and racing efforts in 2011. We’ll find out if the very high cetane rating for GTL fuels offers tuning potential, how it affects flame rate and probably look into nozzle design while we’re at it.

While RenDiesel will not be immediately available to consumers, that day may come in the future. It’s a fuel that can be engineered to spec, a “drop in” fuel with regard to existing diesel engines. CEO Ramsbottom told us they are looking for the price of oil to hit about $75 a barrel to make their operation profitable without government incentives. That seems likely: “I was just on the phone to the united airline guys, and they just came out of a meeting on petroleum,” Ramsbottom told us. “ They said it’s going to average about $92 a barrel next year. Once that starts to happen, we’re back in the range we want. “

So in the future, there may very well be RenDiesel available at the pump. For consumers, the cleaner-burning fuel would offer an unexpected benefit: less soot. With less soot, the particulate trap will take longer to plug and need to be regenerated less often. Fewer regenerations means better mileage. The GTL process does result in a fuel that has less energy density than standard diesel, and energy density is directly related to mileage. When it comes to mileage, it will be interesting to see if the benefit of fewer regenerations outweighs the reduced energy density, or vice versa. Stay tuned.