Banks Sidewinder Blower Test Series

At Banks Power we develop engines for uses ranging from winning wars (military) to winning races. We have done this, including the military part, since 1975. In those 40 years we have advanced our art and been on the winning team in building and powering all types of cars, trucks and boats, all over the planet.

Since 1965, we have been in the forced induction business. We’ve been in the racing engine business, all told, since August 16, 1958. And, ya know what…the past few years of Super-Turbo development have been, and continue to be, the most inventive of my life! I’ve been having a creative burst since last November. I must be driving my crew crazy…!

I’m going to share as much of this experience, and know how, as I can. If you’re into engines, multiple supercharging devices aren’t new to you. What’s is new, is how we are matching and controlling these density machines and engines by leveraging the microprocessor. The sensing, computing and control genius of the Banks electrical engineering gearheads, makes it all possible.

It starts with an engine’s power requirement right off idle. In a boat where no multi speed transmission usually exists, it’s like driving from a stand still with the transmission in overdrive, while pulling a long, long, trailer! The problem, and the opportunity to solve it, all started at Bonneville in the Sidewinder Dakota back in 2001.lI’ll tell you about that as we go along.

On my way to Bonneville 2001 towing my pit trailer loaded with tools, jacks, stands work bench and race tires. I just filled up with diesel at the Flying J. My Super-Turbo program resulted from a marine engine design that started with this record setting Banks Turbo Cummins

My dragster is my blower response and control, test bed. On the digger, our smallest blower in the test series will be a Whipple 200, next will be a 275 and then we plan a Whipple blowing into two turbos. Next we plan a 8-71 GMC twisted rotor, as well. The 8-71 would ultimately be blown by two turbochargers, reversing the order. Blower air management is a big deal on a diesel and that’s what I’m trying to perfect here. That and active boost control of the turbos at the same time.

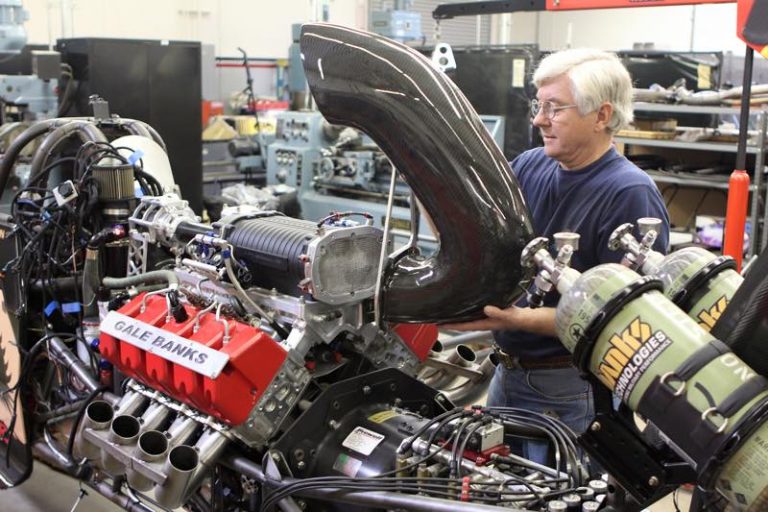

We are not afraid of a little Nitrous among friends! We’re experimenting with blower sealing/cooling with our StraightShot water/meth. Check out the nozzles around the blower air inlet at the rear of the Whipple.

Here’s the blower with our homemade carbon scoop. You can see the manifold air density (MAD) controller at the front of the manifold next to the drive snout.

Banks Sidewinder is a 272 inch Spitzer double slip joint setup, the turbo air inlets are right in front of the slicks. This engine and turbos are now being replaced with our 427″ Big Pin Stroker Engine.

One Long Mother don’t ya think?