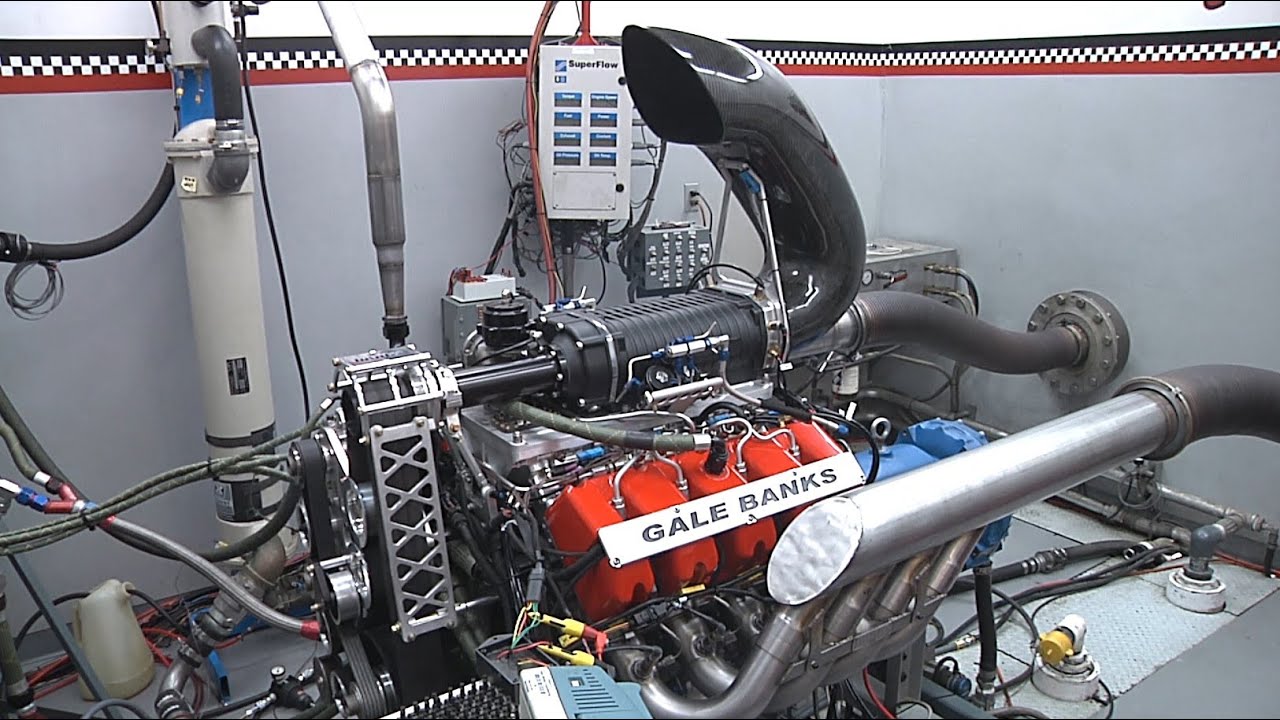

FirstFirst Fire Banks Supercharged 871S Diesel V8

Here’s a short first fire video of our Blown Duramax based dragster engine. This setup uses our cold side PWM controlled waste gate. As the waste gate air bypass becomes necessary it opens and blows the camera back. Watch for it!

We have recently redesigned the bearing and mounting system in this 3100 Taylor absorber to allow a Dyno speed increase from 4,000 rpm stock Dyno, to 7,000+ rpm now. Ceramic Ball Bearings and a very specific lubricant, plus some extra bearing positions, provide for the speed increase.

A complete mounting redesign allows us to bolt the Dyno to the engine as if it’s a transmission. A drive plate with two stage, damping spring sets, decouples the Dyno from the torque spikes, as if a clutch disk were present.

This was our high torque medium speed cell. Now this Dyno cell is for Diesel or highly boosted spark ignition engines, up to 3,000 lbft of Torque and engine speeds over 7,000 rpm. We have enough design overhead to allow approaching 8,000 rpm for short time periods.

I think I just realized why my wife won’t let me repair our appliances, like the washer or dryer. It’s pretty obvious that I’ll hot rod anything, and I think I’ve infected everyone that works here… Is that wrong?

And, on the hotrodding front, our drag race Diesel program recently hit our AutoMind ECU rev maximum at 6,300 rpm. The AutoMind injector triggering has now been redesigned to allow fuel cut as late as 7,800 rpm and a hard limit of 8,000rpm. Yep, we hot rodded the ECU…

Gale Banks Fire Banks Supercharged 871S Diesel V8

Here’s a short first fire video of our Blown Duramax based dragster engine. This setup uses our cold side PWM controlled waste gate. As the waste gate air bypass becomes necessary it opens and blows the camera back. Watch for it!

We have recently redesigned the bearing and mounting system in this 3100 Taylor absorber to allow a Dyno speed increase from 4,000 rpm stock Dyno, to 7,000+ rpm now. Ceramic Ball Bearings and a very specific lubricant, plus some extra bearing positions, provide for the speed increase.

A complete mounting redesign allows us to bolt the Dyno to the engine as if it’s a transmission. A drive plate with two stage, damping spring sets, decouples the Dyno from the torque spikes, as if a clutch disk were present.

This was our high torque medium speed cell. Now this Dyno cell is for Diesel or highly boosted spark ignition engines, up to 3,000 lbft of Torque and engine speeds over 7,000 rpm. We have enough design overhead to allow approaching 8,000 rpm for short time periods.

I think I just realized why my wife won’t let me repair our appliances, like the washer or dryer. It’s pretty obvious that I’ll hot rod anything, and I think I’ve infected everyone that works here… Is that wrong?

And, on the hotrodding front, our drag race Diesel program recently hit our AutoMind ECUrev maximum at 6,300 rpm. The AutoMind injector triggering has now been redesigned to allow fuel cut as late as 7,800 rpm and a hard limit of 8,000rpm. Yep, we hot rodded the ECU…

Gale Banks