Pump The Power

Family & Performance Boating November 2005

Installing a Full Banks PowerPack on a Ford F-350

As the loads we’ve asked our trucks to haul have gotten larger and heavier, tow vehicles have had to become more powerful and fuel efficient to be able to safely and economically tow these heavy loads. As we walk the boat ramps, the other places where trucks rule, it seems that diesel-powered trucks are becoming more and more predominate. Although lately it seems that diesel-powered trucks outnumber gas-powered trucks by a large margin, there is still a significant group of consumers that choose gas over diesel. As with their diesel counterparts, gas-powered truck owners are always looking for ways to give their vehicles even more power and better mileage.

To find out what kind of power options are available for gas-powered trucks, we went to J&D Performance in Ontario, California. We’ve seen what kind of power and performance the guys at J&D can make in a diesel-powered truck, so we figured we couldn’t go wrong in following along as they wrenched more power out of a common gas-powered truck. After a quick phone call, we were set and the guys at J&D had a customer’s stock ’99 Ford F-350 Dually with a 6.8-liter V-10 ready for buildup.

The test truck was bone stock with 92,000 miles. The truck is used as a daily driver and does part-time duty towing a 28-foot toy box during the winter months and a 25-foot boat during the summer months. According to the owner, the truck runs well but is under-powered for its size. The owner wanted more power for daily driving and towing but did not want to sacrifice mileage, economy or smog-legal status.

To start off, the crew at J&D did some baseline evaluations of the stock truck. The first tests were done on the road. The truck was put through four on-road evaluations–the 1/8 mile and the 1/4 mile at 30 mph to 50 mph, and 50 mph to 70 mph. In stock trim the truck ran the 1/8 mile in 11.01 seconds at 65.76 mph, the 1/4 mile in 17.04 seconds at 81.58 mph, 30 mph to 50 mph in 3.92 seconds and 50 mph to 70 mph in 5.77 seconds. On the road the truck produced 11.5-12.5 miles per gallon during normal driving. With the on-road evaluations completed, J&D put the truck on their in-house chassis dyno for some baseline, rear-wheel power numbers. On the dyno, the truck made 207.81 hp at 4,400 rpm and 314.87 lb-ft of torque at 2,900 rpm.

J&D knows that the best way to improve power and economy in a gas-powered truck is to improve airflow into the engine and then to improve the exhaust flow out of the engine. Once that is complete, adjusting fuel and timing will optimize power output and fuel economy.

For this buildup, the crew at J&D decided to do the buildup in a two-part series. First, being a local Banks Power dealer, the crew set out to install a full Banks PowerPack®. Second, they set out to further improve power and performance by adding hand-selected items that they know make “real-world” power (a high flow cat, larger intake system, computer programmer and larger throttle body). The second portion will come in a subsequent issue.

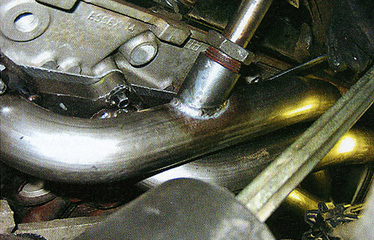

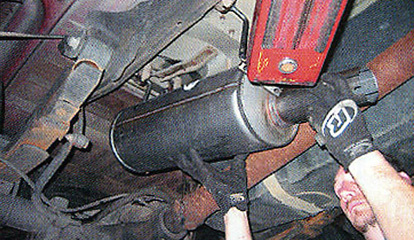

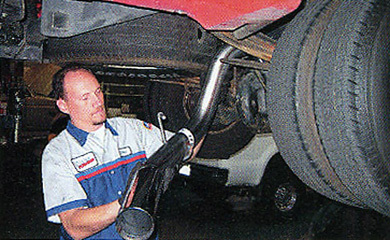

For the first part of the buildup, J&D worked with the crew at Banks and began installing the full Banks PowerPack. They started by removing the stock exhaust and installing the PowerPack’s full-length headers, Y-pipe and cat-back exhaust system. Banks headers are made using a 0.625-inch flange and stainless steel head pipes. Banks’ cat-back exhaust system uses the Banks Monster muffler and stainless 3-inch mandrel-bent tubing. With the exhaust complete, J&D and Banks installed the air filter replacement and the Banks TransCommand to improve transmission function. The stock air filter assembly is replaced with a Banks custom housing, which dramatically improves the flow of air into the engine. The TransCommand increases transmission line pressure, changes shift points, changes converter lock-up points and helps to eliminate unnecessary downshifting while towing on long grades.

With the first part of the installation completed, the truck was taken back to the street for an evaluation of the PowerPack system. The truck was again put through four on-road evaluations, the 1/8 mile, the 1/4 mile, 30 mph to 50 mph, and 50 mph to 70 mph. With the PowerPack installed, the truck ran the 1/8 mile in 10.08 seconds at 68.47 mph, the 1/4 mile in 15.94 seconds at 81.58 mph, 30 mph to 50 mph in 3.10 seconds, and 50 mph to 70 mph in 4.90 seconds. The PowerPack produced an improvement of 0.93 seconds and 2.71 mph in the 1/8th mile, 1.1 seconds and 1.91 mph in the 1/4 mile, 0.82 seconds in the 30 mph to 50 mph, and 0.87 seconds in the 50 mph to 70 mph run. During normal driving the truck produced 12.7-13.5 miles per gallon (a 1-1.2 mile per gallon improvement over stock).

With the on-road evaluations completed, J&D put the truck back on their in-house chassis dyno for the PowerPack’s rear-wheel power numbers. On the dyno, the truck made 232.96 hp at 3,900 rpm and 343.06 lb-ft at 3,400 rpm. These numbers showed an increase of 25.15 hp and 28.19 lb-ft of torque at the rear wheels. Once the dyno testing was completed, the truck was returned to its owner for evaluation. The owner reported a substantial power increase, a noticeable mileage increase and an overall improvement in driveability.

For the first part of this buildup, we learned that by simply improving the flow of air into the engine and the flow of exhaust out of the engine, we were able to significantly improve the usable power of the truck. For part two, we’ll follow along as the crew at J&D adds their own selection of parts to further improve the power and mileage of the ’99 V-10.

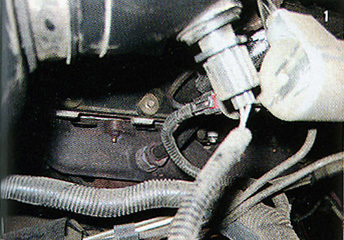

1. The factory cast iron exhaust manifolds are a 5-into-1 Log-type design and are very restrictive.

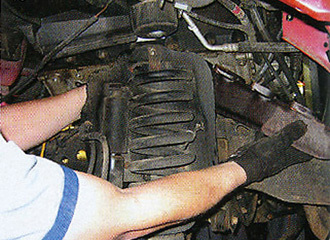

2. There is very little clearance between the factory exhaust manifold and the frame on Ford’s V-10 SuperDuty.

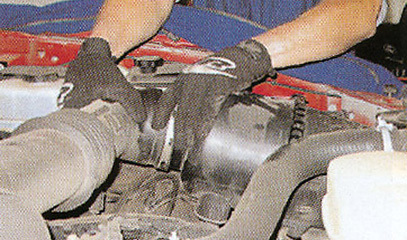

3. The technicians begin by removing the factory air box to provide easier access to the exhaust manifold.

4. The intake is completely removed from the truck.

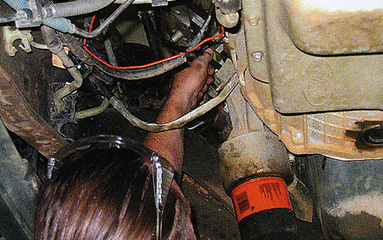

5. With the truck on the lift, the factory exhaust is cut out of the truck.

6. Banks’ new exhaust system is in the box and ready to go on the truck.

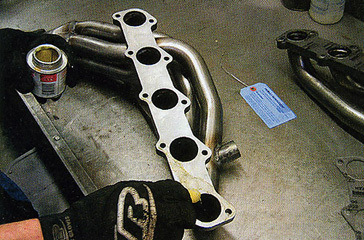

7. Banks headers use massive flanges and full stainless steel construction.

8. Here, the technicians laid out the intake and exhaust portion of the Banks PowerPack®.

9. The factory cat pipe is carefully removed from the truck as it will be re-used later.

10. With six bolts removed, the crossover pipe is out of the truck.

11. Here’s an underside look of the restrictive exhaust manifold.

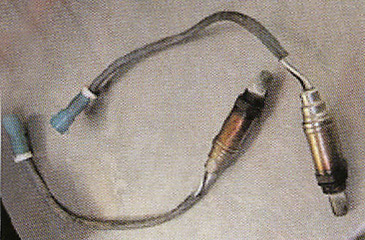

12. Although not included in the kit, J&D Performance recommends replacing the oxygen sensors when you do a complete exhaust change.

13. All the hardware to complete the exhaust install is included in the PowerPack® kit.

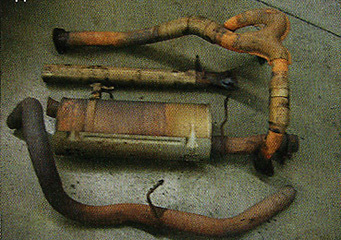

14. With the stock exhaust completely removed from the truck, you can see just how restrictive it is compared to the new Banks kit.

15. With the bolts all removed, the exhaust manifold is pulled out the fender.

16. Here you can see the factory aluminum head and exhaust ports.

17. Broken exhaust bolts are a common problem with this install.

18. The factory exhaust manifold is next to the Banks header.

19. Once the exhaust manifold is removed, the mounting surface is thoroughly cleaned and prepped for the new header.

20. Removing the headers requires a special stand to allow the technicians to lay across the engine of these large trucks.

21. The technicians prep the header for gasket install.

22. The clearance is very tight when installing the new headers.

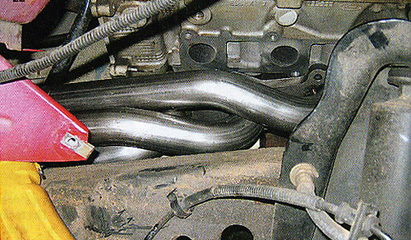

23. Once installed on the truck, the headers are an excellent fit.

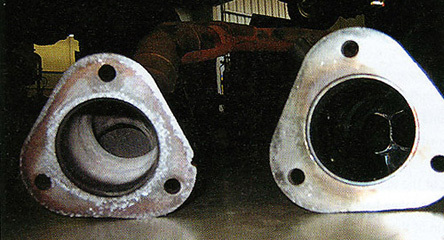

24. Here is the difference between the factory 2.5-inch exhaust and the Banks 3-inch exhaust.

25. All of the factory emissions are retained with the new Banks exhaust system.

26. Once installed, the Banks headers clear the suspension and transmission with plenty of room.

27. The new passenger’s side of the crossover pipe is installed on the truck.

28. The new driver’s side of the crossover pipe is installed on the truck.

29. Both portions of the crossover pipe are attached just above the transmission mount.

30. New oxygen sensors are installed in the Banks system.

31. The crossover pipe is bolted to the new headers.

32. Here’s an overall view of the crossover and header system on the truck.

33. In order to retain legal emissions status, the cat pipe is re-installed.

34. All of the factory hangars are used to install the new muffler.

35. The Banks muffler is maneuvered into place.

36. After the tailpipe is installed, the exhaust will be complete.

37. The tailpipe is maneuvered between the shock and spare tire.

38. The Banks tailpipe is moved into place.

39. Here’s a look at the factory exhaust manifold removed from the truck.

40. This is the factory muffler removed from the truck.

41. (165) This is the header installed with all of the emissions attached.

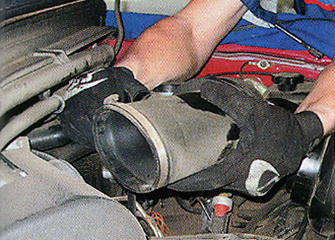

42. This is Banks’ new intake housing next to the stock intake housing.

43. The new intake housing is installed in the truck.

44. The Banks washable filter is installed, and the remaining portion of the factory intake is put in place. The truck is ready to run.