Why Big Air Density Makes a Big Difference

In this column, we’ll discuss air and how it relates to diesel engines. In addition, we’ll explain effective ways to improve airflow and air density and also dispel some myths about airflow. And in the process, we’ll explore a big misconception about diesel tuning.

Unlike gasoline engines that throttle by air, a diesel engine throttles by fuel. Therefore, a diesel tuner will add more fuel to the engine, creating greater power. The misconception here is that a tuner is all you need. And that’s a huge mistake. This is because the tuner is only part of what makes power in diesel applications. “Air” is the other half of the power equation. Or, more specifically, “air density,” which is the weight of air in a given volume measured in pounds per cubic foot. In other words, the more a cubic foot of air weighs, the more oxygen there is in the air.

Adding additional fuel to a diesel engine without adding additional air has two dramatically negative effects. First, by dumping fuel into a diesel without the appropriate amount of air to go along with it, a considerable portion of the fuel does not completely combust. This uncombusted fuel is often seen coming out of a diesel’s tailpipe as black, sooty smoke. It’s wasted fuel. What I like to call, “horsepower you can see, but can’t use.” All this smoke contaminates the engine’s oil at a much faster rate than normal. Here’s what happens: Modern engine oils typically contain a chemical that gives the oil its extreme pressure capability. You might call this an “anti-wear agent.” When a massive amount of smoke is present, soot invariably gets past the rings and into the oil, where it binds with the chemical, disabling it. When oil loses its anti-wear agent, internal engine parts wear faster.

Secondly, incomplete combustion builds hotter exhaust gas temperatures (EGTs). When exhaust gas temperatures rise up to a certain level, the computer tuner begins cutting back fuel. This is exactly what you don’t want to happen.

Now that you know the bad things that happen without providing enough air to a diesel, let’s talk about the good that providing enough air does. Air provides oxygen, which allows fuel to properly combust. With proper combustion comes more power, but without smoke and without the associated EGTs.

A four-stroke diesel engine ingests its own displacement of air every two revolutions. In fact, an engine’s cubic inch or cubic liter displacement is calculated by this amount of air and the number is unchanging. In other words, a 6.0-liter (366 cu. in.) engine takes in exactly 6 liters (366 cubic inches) of air every two revolutions. The only way to increase this volume of air is to turn the engine faster. Getting a diesel to rev higher and live a long life takes an enormous amount of work and is expensive.

Here are some less difficult and less expensive ways to provide more oxygen to the engine. The trick is to make the air denser by increasing airflow. The two main airflow improvers are turbochargers and charge-air coolers. (Although everyone calls them “intercoolers,” their correct name is charge-air cooler.) If the diesel already has a turbocharger, there are more efficient turbos available. Turbochargers compress air and when air is compressed, it gets hotter. In “turbo-speak,” greater efficiency means the turbo heats the air less as it compresses it and leaves the air denser. Changing a turbo is an expensive proposition, but many times the results are well worth the price in more boost, quicker spool-up, and lower boost temperatures.

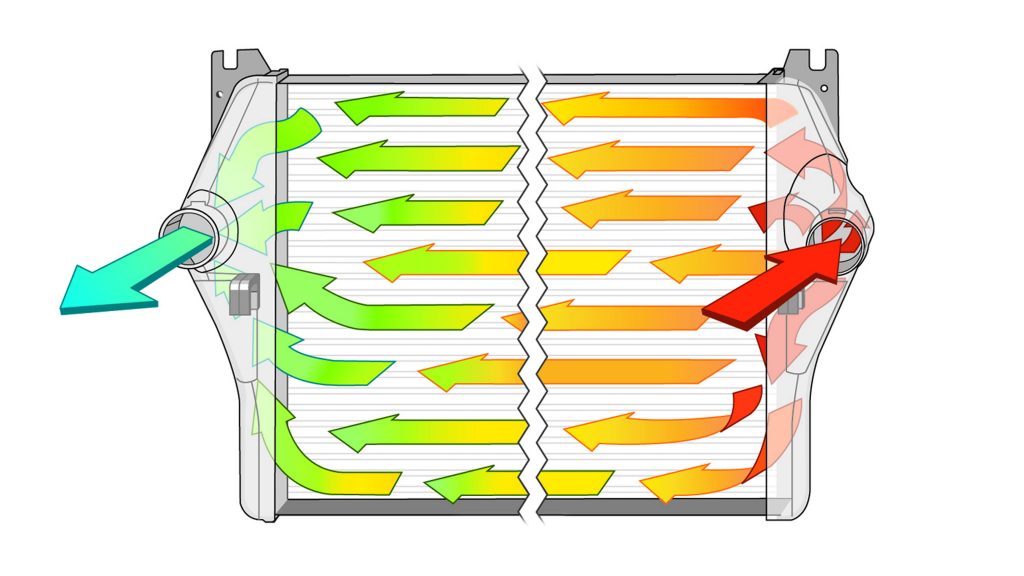

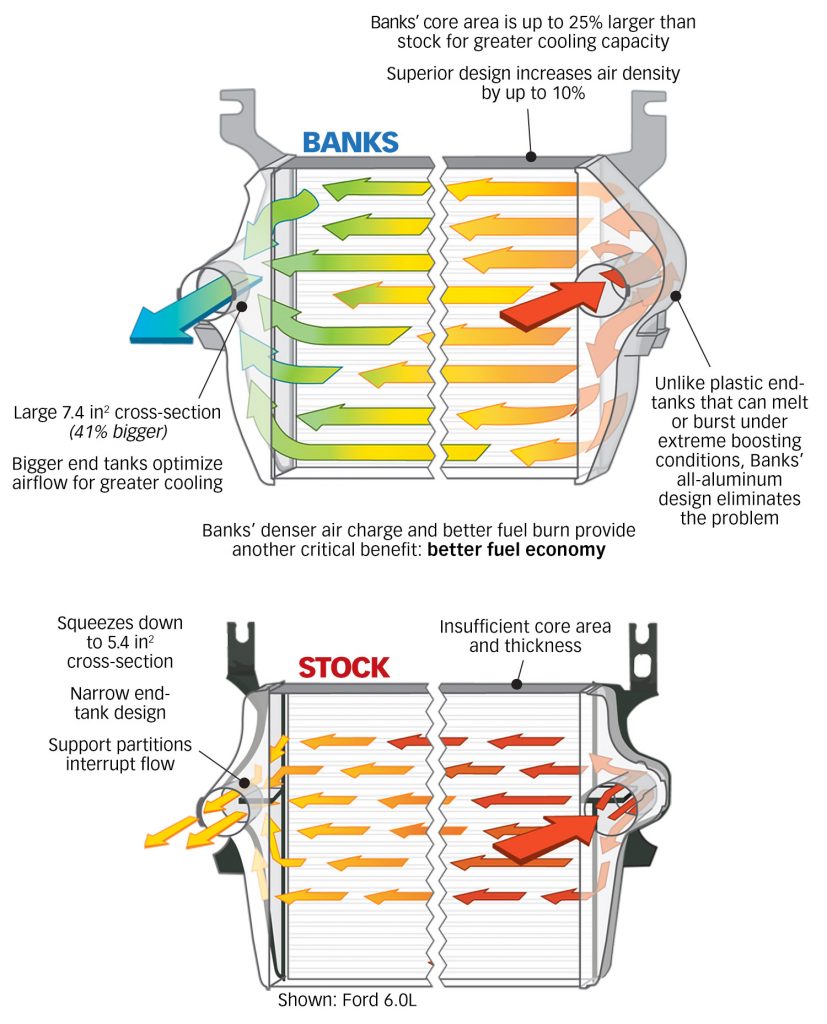

Next, larger and more effective charge-air coolers increase air density by substantially reducing the temperature of the pressurized air from the turbocharger to the intake manifold. By lowering boost air temperature, the denser air is more oxygenated and allows complete fuel combustion. There is also an excellent byproduct of lower intake air temperatures; they produce lower EGTs. If EGTs never build to the temperature where the computer tuner limits fuel delivery, all of the additional power is always available. Lower EGTs also help to reduce the thermal load on the engine and its cooling system, which keeps them running cooler as well.

Well-engineered charge-air cooler cores and end tanks with greater airflow also reduce pressure loss, which improves air density further. Within some factory charge-air coolers, the airflow inside is so poor that some cooling passages don’t even get used. In turbo-speak, charge-air cooler effectiveness is measured by its percentage of increase of temperature recovery as compared to ambient air temperature. Better, larger charge-air coolers are one of the best bang-for-the-buck performance gains available.

Boost tubes are the tubes that take the pressurized air from the turbocharger to the charge-air cooler and from the charge-air cooler to the intake manifold. Original engine manufacturers (OEMs) commonly flatten areas of boost tubes for cost savings over additional engineering hours spent routing the boost tubes more efficiently. Aftermarket companies can find gains here by both using larger tubing, as well as better routing. Larger tubing with the absence of flat spots and sharp curves equals better airflow. Any restriction that reduces pressure also reduces air density. Therefore, smooth large-diameter boost tubes effectively add air density by having less of a pressure drop than the factory boost tubes.

Of course, a vehicle’s airbox is where the outside air comes into the engine. Due to cost restraints, factory airboxes usually allow for a well-engineered aftermarket airbox to do a much more efficient job at directing the air into the engine. The best-engineered airboxes are sealed units that take the air in from the front of the vehicle and create the least-restrictive path to the turbocharger.

Aftermarket filters-on-a-stick don’t work very well, even if the air filter element has an enclosure around it. They still tend to induct hot underhood air, which is far less dense than outside ambient air. Remember, just because an aftermarket airbox system or filter-on-a-stick makes more noise, doesn’t mean it’s making power or increasing air density. Make sure you get a dynamometer-tested airbox that actually makes power and increases air density instead of just making more noise. If you’re curious about your stock intake or the new one you just purchased, you can always take your own measurements using an iDash DataMonster and iDash SuperGauge and a few pressure and temp sensors. Read more on sensor setups here.

There is a common myth that aftermarket diesel exhaust systems improve airflow into the engine. But they don’t. Their benefit is, they reduce backpressure out of the engine. Less backpressure means a more efficient engine that isn’t fighting to push exhaust out.

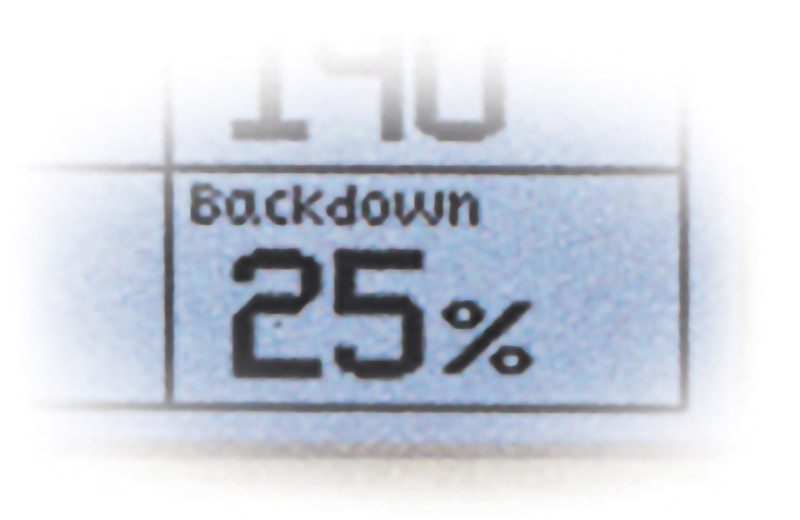

Finally, let’s talk about the term “backdown.” Backdown is a relatively unheard-of term that describes what engineers refer to as “derate.” Backdown is the percentage of additional fuel that is reduced by an electronic tuner as exhaust gas temperatures rise. In other words, it’s the amount of additional horsepower claimed that the customer doesn’t receive. Some manufacturers even show you this percentage of backdown on their little computer screen readouts. Think of backdown like this: if a manufacturer is claiming its diesel tuner produces 150 horsepower and the backdown is 25%, the actual horsepower gain is only 112.5 horsepower. That means you’re not getting 37.5 horsepower!

Backdown happens because there isn’t enough airflow. If there were enough air, there wouldn’t be a need for backdown. Everyone would have all of the power the tuner manufacturers promised. But, they don’t.

Improving airflow and air density makes more power at lower EGTs than by adding a computer tuner alone. You’ll get higher continuous, useable power—in other words, more of the power you paid for, more of the time. And isn’t that what it’s all about?

Banks intercoolers create cooler, denser air, and Banks’ High-Ram intake, with its larger size and less restrictive shape, does a far better job than the puny stock intake of flowing that oxygen-rich air into the cylinders. High-Ram increases boost without raising backpressure at the turbine, resulting in instant torque, a more responsive engine, and greater fuel efficiency.

Is your tuner giving it to you and then taking it away? Tuner manufacturers advertise power numbers you’ll never reach unless you deal with airflow. Case in point: a competitor’s ad that shows a BACKDOWN window. This is the percentage of fuel—and power—you can’t use because they didn’t add airflow. The longer you stay on the throttle, the higher the number gets. Unless it reads 0, you’re not getting the power you paid for!

Gale Banks spoke at The Wally Parks NHRA Motorsports Museum on the topic of “Air Superiority–Sometimes it’s good to be dense,” which covers how intake density is the key to power. Whether you’re just getting into the world of internal combustion or you’re a seasoned gearhead, you’re bound to learn some new things about the past, present, and future of engine technology.