Protect Your Differential

Our rigorous testing of popular diff covers on the market revealed an unexpected flaw: they actually hurt power and fuel economy. This discovery inspired the creation of a groundbreaking design so innovative that it earned a United States Patent. The design incorporates Ram-Air scoops that direct air through channeled fins, cooling the differential and internal oil temperatures.

Ram-Air differential covers deliver superior fluid flow and fluid dynamics, outperforming stock and flat-back high-capacity covers while using less lubricant. With Banks, you can extend the life of your gears, minimize fluid usage, and save money on maintenance.

Banks Ram-Air differential covers are available for Ford, GM, and RAM 3/4 and 1-tons with more on the way!

Full Video Transcript

00:01 the fluid dynamics is so effed up it’s i couldn’t even imagine how bad that actually is i’m gayle banks and i’m here to tell you what aftermarket depth cover guys don’t tell you here we have three differential covers for the ford sterling axle here’s your stock one here’s the new bank’s ram air

00:34 and here’s a representative of all the flat back covers you’ve seen on the road for the last 20 years are they the same not even close let me show you notice the stock one is curved why well axle manufacturers want the gear loop to travel up and over the ring gear without disruption

00:57 that’s why the bank’s ram air cover honors the stock shape ever aim a fire hose at a brick wall that’s what’s happening inside these flat back covers and it’s all bad does anything get to the ring and pinion interface does anything get to that front pinion bearing at all well i’m not

01:15 superman i can’t see through these things what i did was i got mike in the machine shop who normally builds engines to go put the mag high tech on the bridge port and just mill off that flat back right down to where the radius in the casting begins it duplicates exactly

01:35 the insides of the mag high-tech the mag high-techs on the truck let’s see what’s going on inside the cover all right curtis go ahead and idle it i can already see aeration forming in here and we’re just at idle the thing you don’t want to do is unnecessary work to the fluid

02:02 it aerates it and it heats it so here we are at five miles an hour we’re already pushing the lube up and it’s falling off to the sides nothing’s been being taken to the pinion area let’s go to 10. all right 10 miles an hour we’re getting some weird action here look at this

02:30 same over here it’s just water falling off but what’s going on here dynamically okay let’s take it to 15. all right now we’re driving it very little is going with the ring gear we’re at 15 miles an hour and very little is going with the ring gear we just got this kind of waterfall action

02:55 off to the left-hand side look at that even the dipstick is screwing up the flow let’s go to 20. look at this it’s driving the lube right into the flat surface oh man i can see in there we still don’t have any lube going over with the ring gear and we’re at 20 miles an hour so you can see

03:27 down in the bottom here it’s driving the fluid right into the surface and then it’s going up up to the top where it hits and water falls off let’s go to 30. this ain’t good oh it sounds like we shifted gears huh just more intense same problem it’s really starting to put

03:57 a lot of air in the loop see how it’s getting wider the aeration is taking place on that impact and this impact at the top let’s go to 60. man that’s intense that is really intense i don’t know if any of it is going over the ring gear to lube the front pinion bearings

04:25 and the pinion to ring your interface that frictional surface very high load there when you get air in the oil like this the film strength of the lube does this which means you’re wearing it out any rubbing surface especially like the ring and pinion interface doesn’t just touch

04:50 there’s motion there’s relative motion just for the hell of it 70. oh baby i don’t know man i think we’re just making cake better right now or maybe maybe we’re going to do some waffles or something man that is pathetic houston we have a problem the moral of the story is these flat

05:24 backs heat the lube aerate the lube destroy the lube imagine what would happen if we put two more quartz in here like they recommend all that stuff would be amplified in fact maybe we ought to put two more courts into just to see what happens what’s the benefit of more fluid

05:48 well i’m going to tell you right now there is none you have more fluid and it’ll take a little longer to warm up but the warm-up goes beyond what you’d have with nominally four quarts this is six and a half to seven quarts to that mark i fear what we’re going to

06:06 see as we go up in speed but let’s take it to 15 15. so we’re going from 5 miles an hour to 15. i can see it water falling off the inside of this surface very little is going around with the ring gear as the thing was designed to do let’s go to 30 30. oh man let’s go to 60. how about that

07:03 the fluid dynamics is so effed up it’s i couldn’t even imagine how bad that actually is unreal can you hear that blasting the cover because i sure can 70 oh baby my only comment here is this is dead wrong there’s this old wives tale that overfilling above the stock fluid level is the thing to do

07:43 i’m calling on that even in the jeep manual they address it caution overfilling the differential can result in lubricant foaming and overheating for efficiency the gears and bearings would prefer the lube to be right around 200 degrees anything more than 200 and you’re taxing the base oil the reality

08:10 is many diffs can run far hotter than 200 degrees in many situations like towing up a grade the lube temp will rise above 250 when you approach 350 the oil oxidizes and turns to sludge in our one-hour dyno endurance test we found it surprisingly easy to reach a sustained temp of well

08:31 over 300 degrees so how do you cool the lube airflow you need high velocity cool air over the cover that’s how the first thing we did was to instrument the truck with several anemometers to measure the airflow under the belly and behind the differential when we were out on the highway we

08:52 recorded temps and air velocity we noticed there was a dead zone right behind the face of the diff cover what we found was a large low pressure zone directly behind the diff cover the differential housing splits the air like a wedge this low velocity dead zone extends as

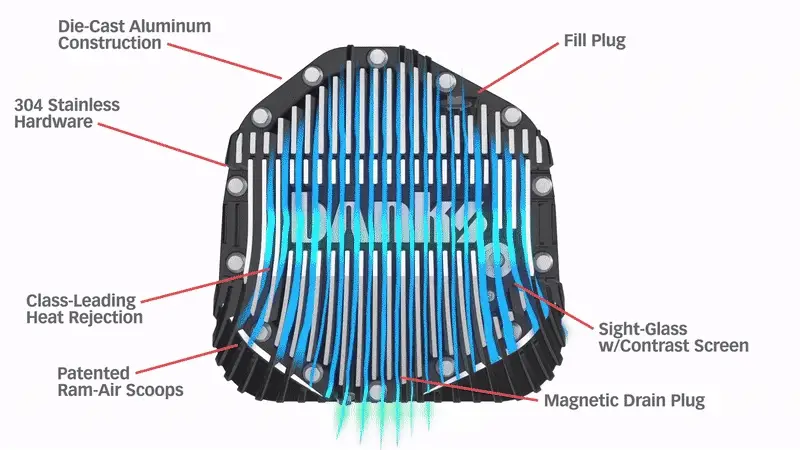

09:12 far out as 36 inches from the back face of the cover this discovery resulted in our patented ram air design as the truck moves through the air cool ram air is forced into the scoops and directed 90 degrees up and through the long thin heat radiation fins as a result the bank’s ram air diff cover

09:36 rejects heat five times better and does so with less lubricant than the flat backs so how do we test it we performed a series of hill climb tests on a stretch of interstate five california’s infamous grapevine the tests were run using the same truck with the same driver and the same load at the same

09:58 time of day and at the same temperature starting with a nominal 78 degree ambient temperature the driver pulled an 11 650 pound trailer with our 19 ford f-250 gross combined weight was 19 750 pounds starting at the same temperature the rear differential was warmed by maintaining a constant speed

10:22 of 55 miles an hour up a six percent grade for five miles ascending over 1600 feet in altitude at the top of the hill climb running the stock diff cover the lubricant temp was 205 degrees filled with seven and a half quarts the mag high tech recorded 199 degrees while the

10:43 banks filled with 3.6 quarts recorded 192 and a half degrees even with less lubricant the ram air cover reduced heat two times better than the flat back during the high horsepower uphill climb but here’s the money shot from the crest to the end of the test running 55 miles an hour for 700 seconds

11:04 at relatively constant elevation the stock cover cooled from 205 to 195. the mag high tech cooled to 192 and a half while the bank’s cover cooled to 178 and a half and our final temp reduction compared to stock at the end of the test was five times better than mag high tech

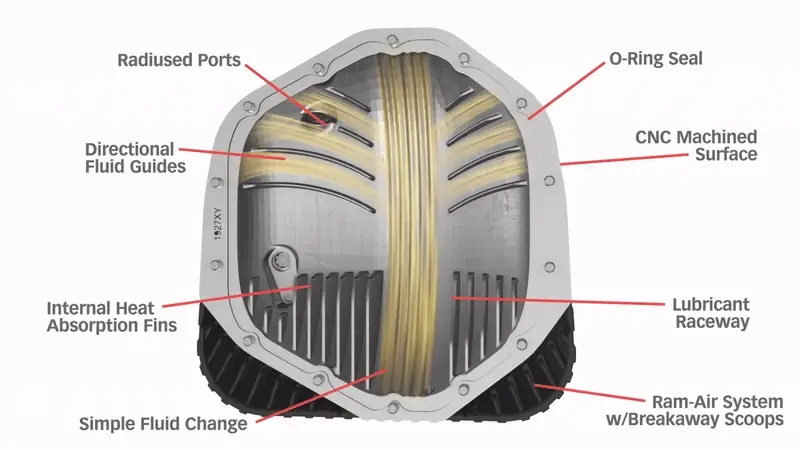

11:29 and by extension all the other flat back diff cover copies here’s how the ram air cover wins over all other covers it starts with a ram air cooling system the cover mates perfectly with a differential housing for unobstructed lubricant flow the ring gear raceway controls lubricant flow to the pinion

11:50 area and the directional fluid guides send lubricant out to the axle bearings it retains the factory spec fill level it’s got a dry mount high pressure o-ring seal no messy silicon or rtv here it’s got an easy access 20 degree back angle fill port with a magnetic plug the

12:10 drain plug is also magnetic and it’s located so you can get every last drop out of the diff and not only does it have a sight glass but the contrast screen allows you to see the level even at a distance longer lasting lube means increased gear life just one look and

12:29 you can see which one is superior the data doesn’t lie nor do your eyes this thing kicks ass for details and test data head to bankspower.com slash diff cover children do not try this at home you