Good Things Come In Threes!

We have designed a new Big Pin Stroker crank, a totally new rod bearing diameter and a new long con rod design, all for our new Banks 870T2B, Duramax V8. It’s our intent to use this improvement everywhere from NHRDA Top Dragster and Pro Stock Truck to Baja Trophy Truck, Bonneville Diesel Streamliner and Marine Offshore engines.

Our 272″ Spitzer, Top Dragster is in the shop! This will be the test bed for our 7 liter Big Pin V8 crankshaft program. The idea is to turn our diesel real fast while making very high cylinder pressure and not break anything, such as the crank or the main caps. Looking for a diesel national record with an ET in the 6.20’s, this year or early next.

We are running the blower first to get our 60′ times worked out, then we will add two turbos. It’ll be a shame to see the zoomies go, but the turbos should be worth it!

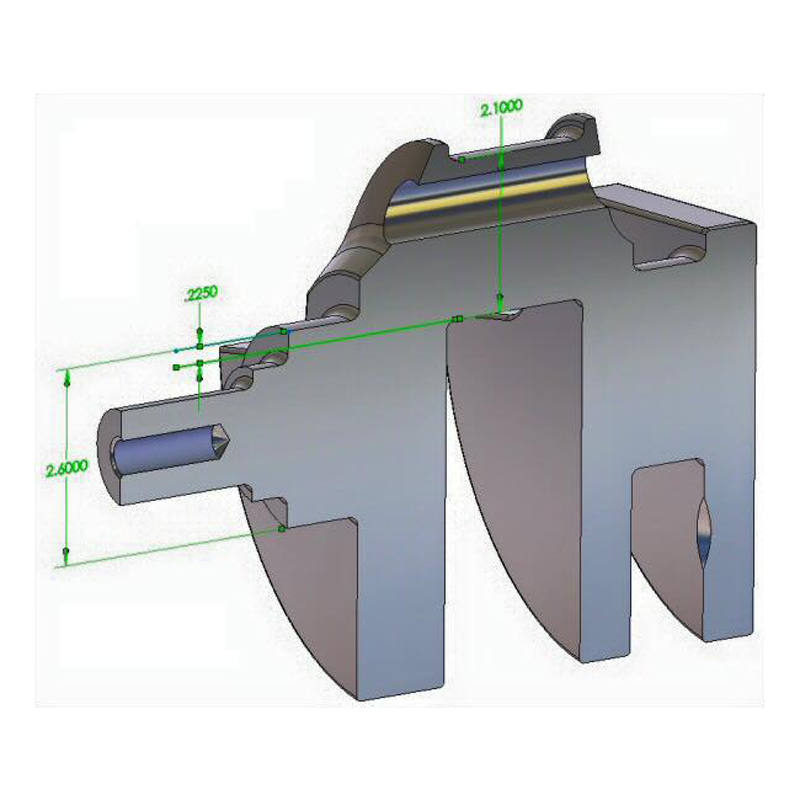

Here’s our new big pin crank, the rod journals (pins) are much larger than the stock Dmax diameter. This allows our increased stroke crankshaft to actually be stronger than a stock stroke version. This setup required a new rod bearing diameter to be created, we have run this setup in software to 7,800 rpm. We intend to go for 7,800 rpm in our dragster, the Banks SideWinder, Type D

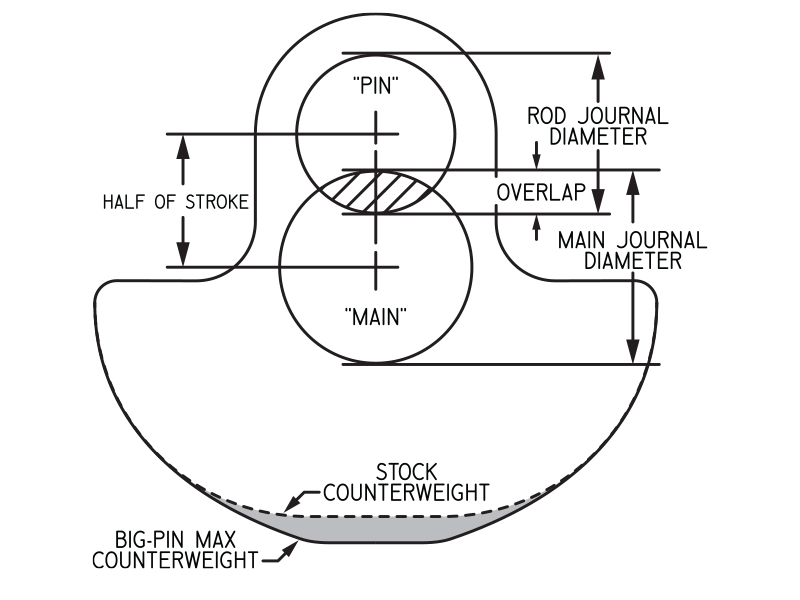

This cross section of a Small Block Chevy 4.25″ Stroker crank, shows the pin to main overlap is almost gone with only .225″ remaining. Our 427″ SBC twin turbo builds use a 4.00″ crank increasing the overlap to .350″. We’re using Tom Leib’s SCAT Billet cranks for these in both SBC and LS Chevy turbo motors.

Here’s a crankshaft section showing pin to main overlap. As you increase stroke the pin moves away from the main reducing this critical connection and weakening the crank, we’ve solved it with our big pin bearing and journal. How much we’ve improved the Dmax will soon be tested on the Dyno and in our SideWinder Type D.