Digitizing our ’66 Chevy | BANKS BUILT Ep 23

Matt and Stephan 3-D scan the front end, wheels, tires, and chassis to begin digitizing LokJaw. The two do this in the raised and a lowered position in order to bring the data into Solidworks. This will allow Matt to design the front engine accessory drive (FEAD), intake air system, and hood hinges on the computer, precisely. Although setup time is increased, designing these parts on the computer will dramatically reduce fabrication time and ensure proper fitment. We can’t have the tires smashing into the Banks Big-Ass filters.

00:00 Intro

00:28 Bed disassembly

02:45 Bed on chassis

04:31 3-D scanning front end

06:19 Designing hood hinges

13:26 Truck bed fabrication plan

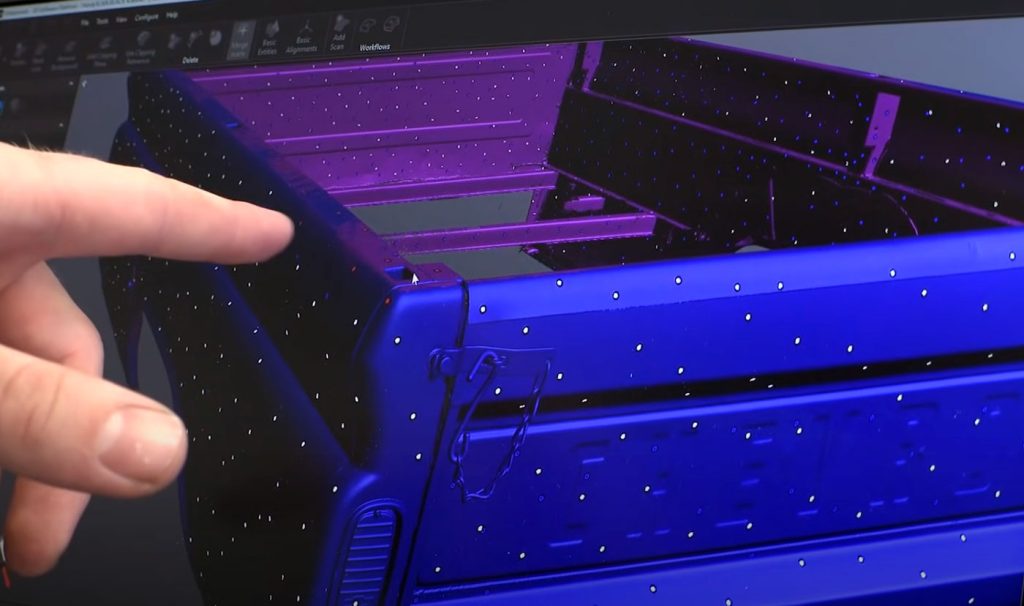

15:51 3-D laser scanning bed

19:31 Next episode teaser

Erik then scans the bed and merges the inner and outer sheet metal into one unit. In theory, this will allow him to cut the bed in half on the digital version and design the dump bed structure and know it’ll work before he even turns on a cutting tool.

After Eric is done digitizing the truck, the team starts working on the braking system for the Supercharged Duramax powered ’66 Chevy. That’s on the next episode of Banks Built.