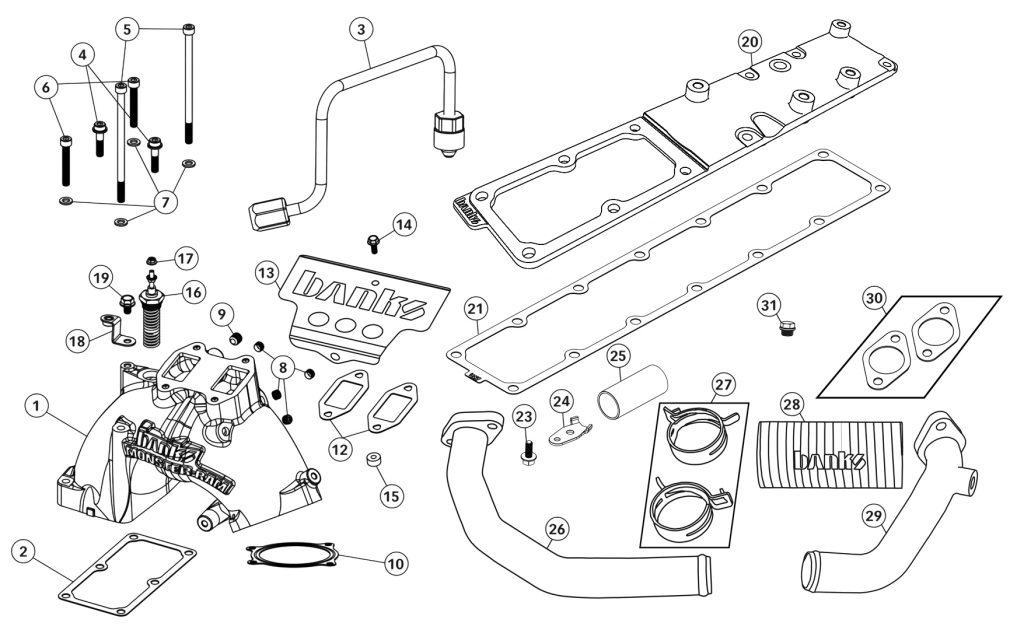

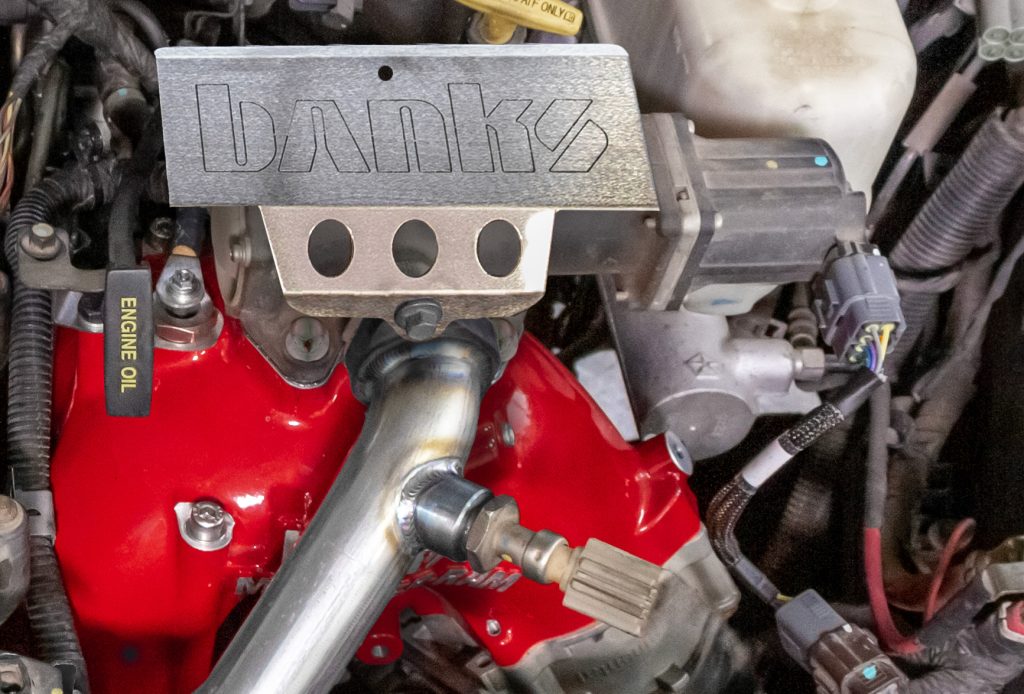

97743 Monster-Ram Intake System for 2019-23 RAM Chassis Cab 6.7L

INSTALL INSTRUCTIONS

Part #s

42805-R, 42805-N

Monster-Ram® Air Intake 2019-2023 RAM Chassis Cab 3500/4500/5500 6.7L Cummins

Does NOT fit Freightliner or Motorhome vehicles featuring the Cummins 6.7L Engine as emission, EGR systems, boost tubes, and intake elbow are unique to those vehicles.

Please read through the following instructions thoroughly before starting your installation. If you have any questions please visit our Support Page.

Monster-Ram w/Intake Plate Install Video

Note: The billet heater plate, Item #20, is transitioning to a cast design (42731) with integrated fuel rail spacers. If your kit ships with this cast heater plate, the fuel rail spacers will not be included or used during installation.

In an effort to make sure you have the right kit for your model year. Visually check which fuel line is included in your kit before starting installation.

Chassis Cab Owners

Take note, this install guide is based on the existing RAM 2500/3500 Pickup Truck models. While the engine and general install procedure are the same, specifics of sensor placement and emission system locations vary on RAM 3500/4500/5500 Chassis Cab Trucks.

Details regarding these changes are being added to this guide with matching photos and specific install steps in the coming days.

IMPORTANT!

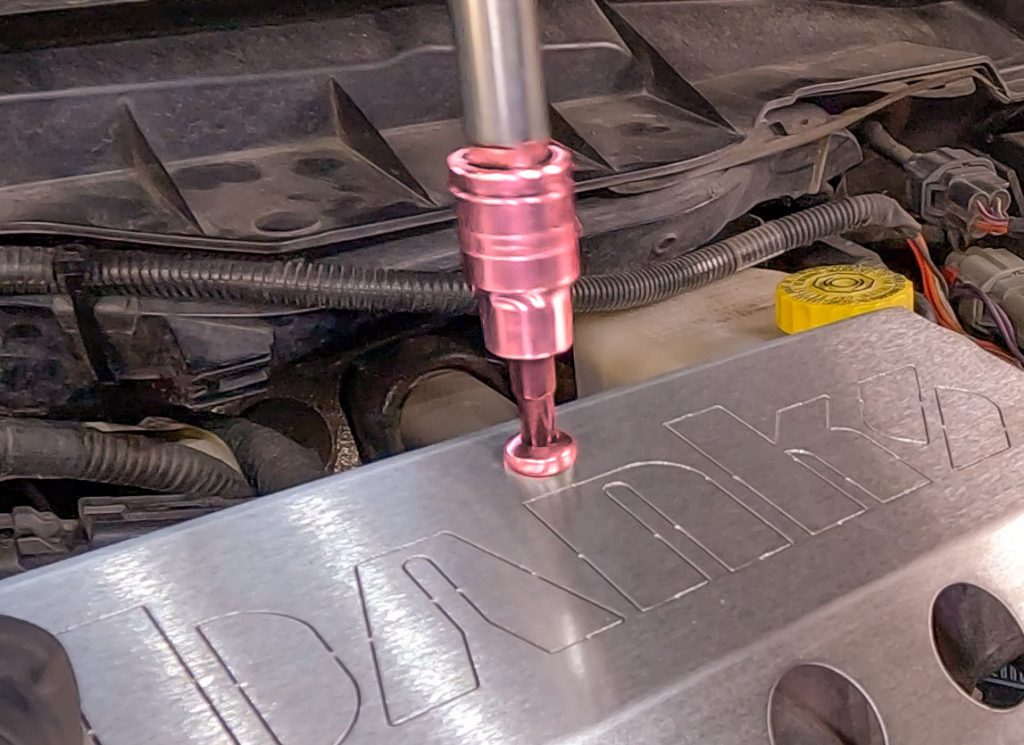

Coil heater preparation: Remove the top hex nut from the threaded post. You will replace the nut with the supplied flange nut as shown. The lower nut must not be removed from the heater coil. The lower nut must remain 1/8″ above the coil heater body.

Take care when installing OEM heater wire ring terminal, it must be sandwiched between the upper and lower nut. If the lower nut is too low, the ring terminal could contact the body of the coil and will short out.

When tightening the nut, it is very important to use a 10mm wrench or socket on the top nut and an 8mm open-end wrench on the bottom nut to prevent the threaded post from rotating. If the threaded post rotates, it can break the ceramic insulation it’s surrounded by.

If the OEM heater wire touches other metal components, an open short will occur.

Copper washer: All kits now ship with a copper crush washer. Place this washer between the coil heater before screwing it into the Monster-Ram.

Coil-Heater Variants

Your kit may include one of two different style heater coils. One with a visible ceramic insulator, or one that isn’t visible. Both offer the same level of heating performance.

Installing a Dual Heater Upgrade?

See our Dual Heater and Billet Heater Upgrade supplement for important wiring information and diagrams.

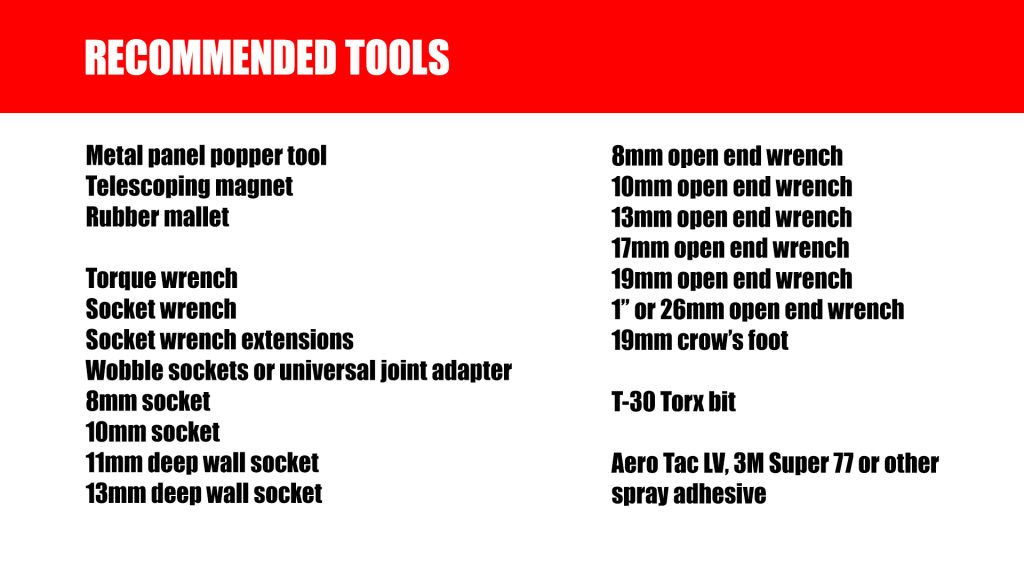

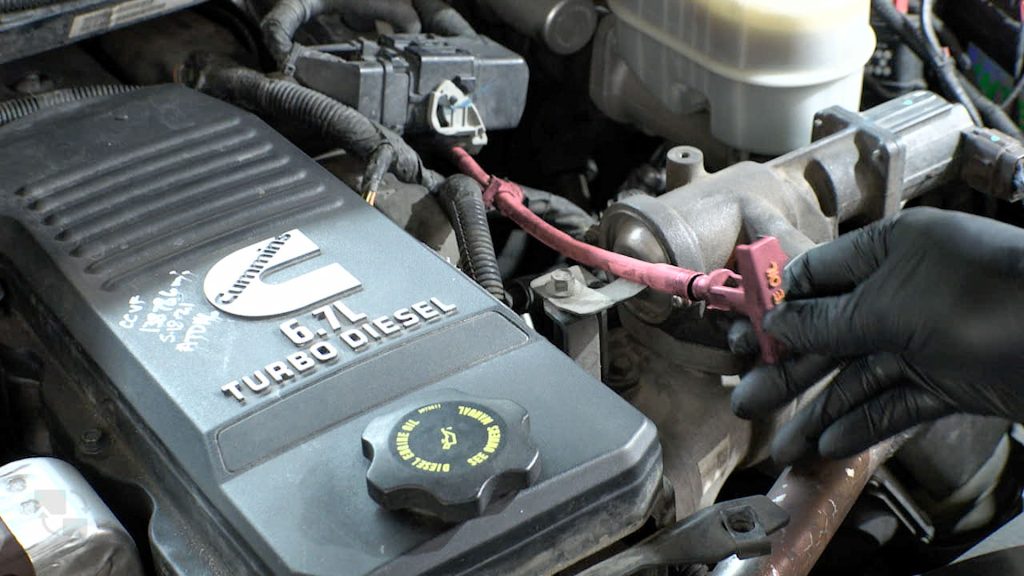

OEM Harness and Sensor Removal

1. Disconnect batteries

Place a rag around each of the negative battery cable ends; this will prevent them from touching the battery again and arcing during the install as you work.

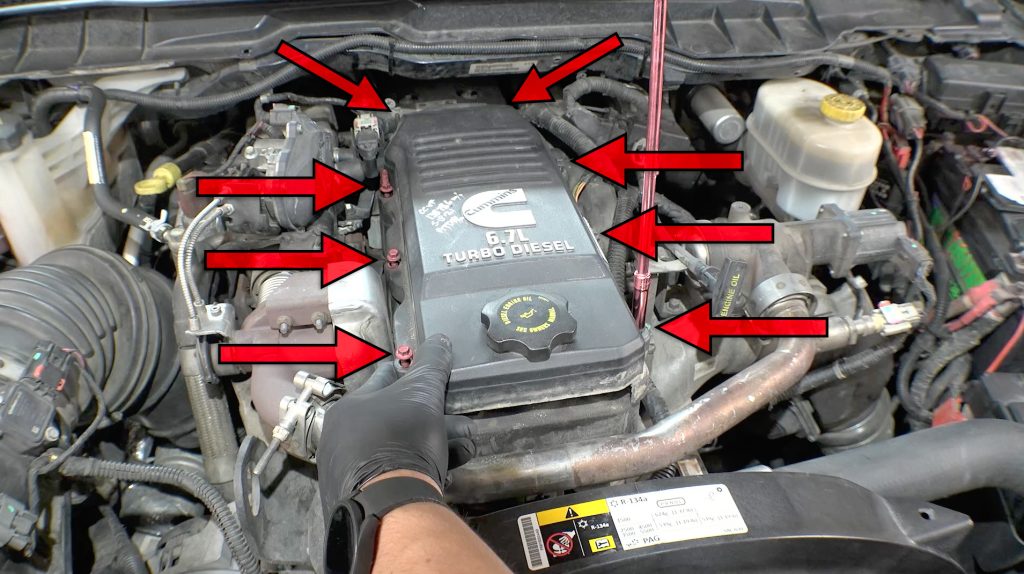

2. Remove engine cover

Remove engine beauty cover. Use an 8mm deep socket to remove the four bolts holding the cover down.

3. Remove dipstick

The Dipstick needs to be removed for the cover to come off.

4. Reinsert dipstick

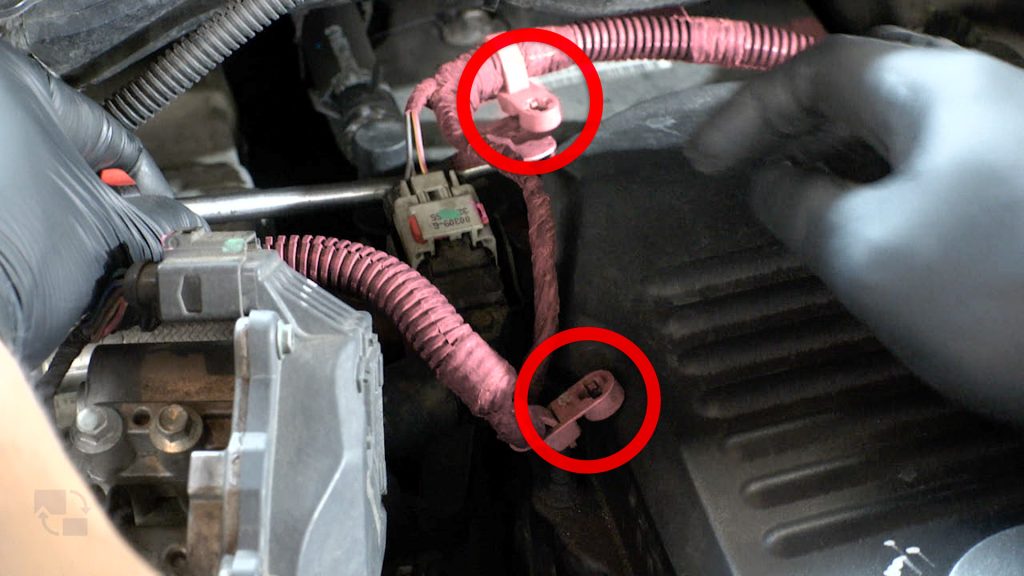

5. Remove cable tie downs

Use a panel popper tool or pliers

Note: The 2 bolts with studs extending up past the head are to be located on the left rear of the cover.

6. Remove cable tie-downs

7. Remove engine cover bolts

There are 8 bolts holding on the cover. A wobble extension and placing the socket on the bolts first helps.

8. Remove oil fill cap

9. Place rag over filler neck

10. Remove bolts holding cross-over tube bracket

This bracket will not be reused.

11. Remove rag & set down cover

12. Install oil filler cap

13. Remove bolt under center of EGR crossover tube

14. Remove and dispose EGR tube p-clamp

15. Reinstall 8 engine cover bolts – Studs in rear passenger side

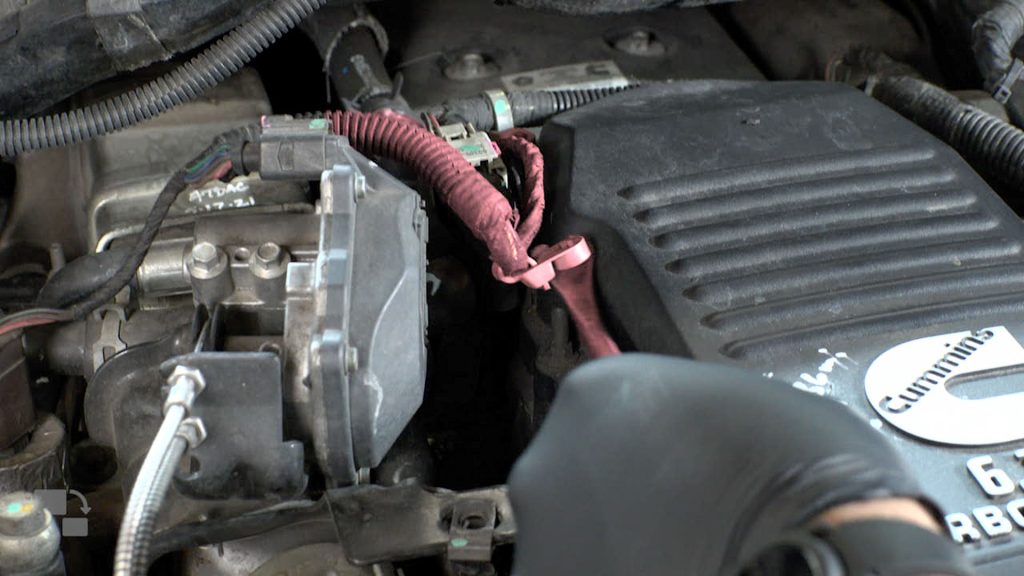

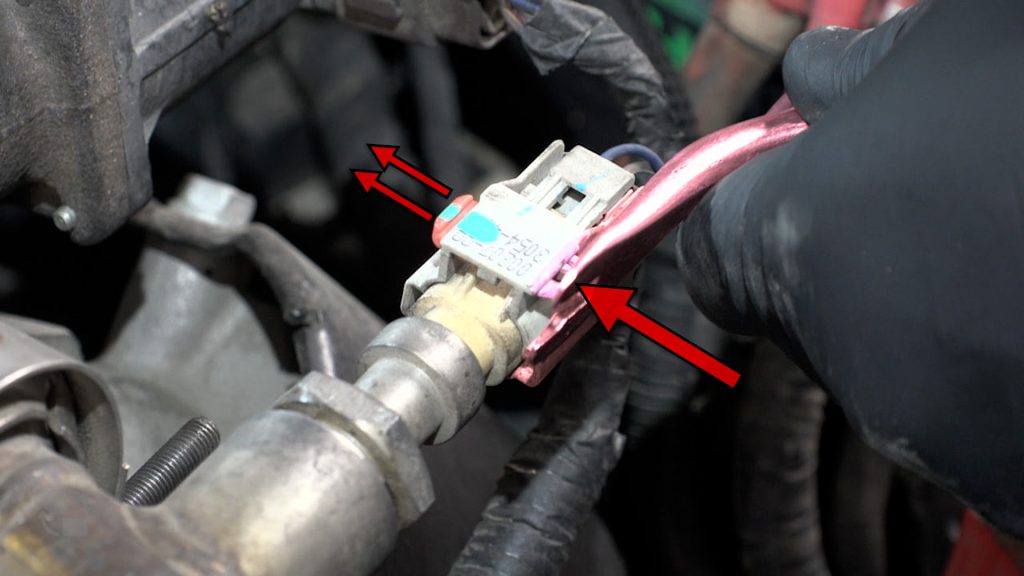

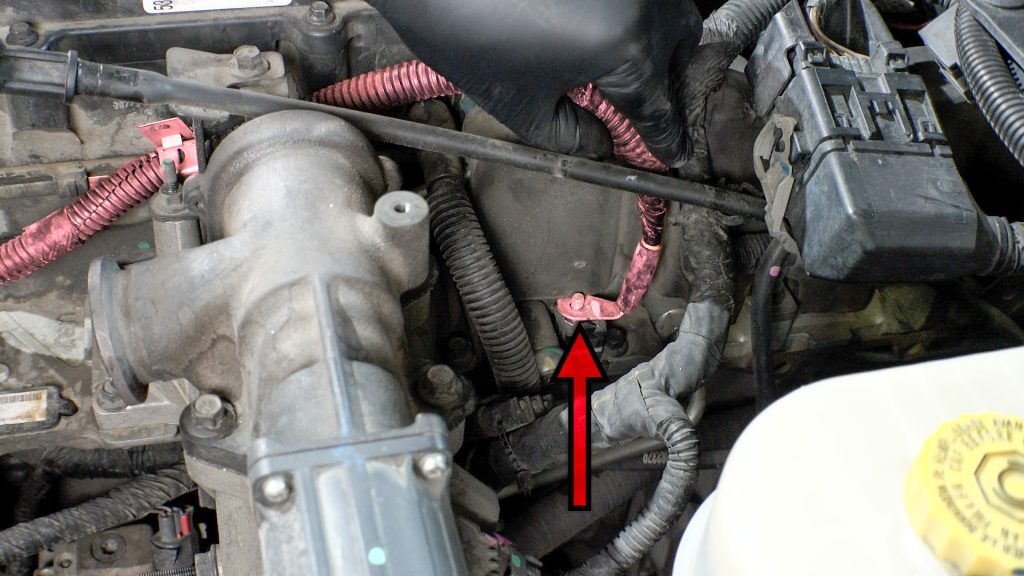

16. Unlock temp sensor plug from EGR crossover

Use a flat-blade screwdriver or pry tool to push the slide-lock.

17. Remove temp sensor plug by pinching It

18. Remove EGR valve plug – located on Back of EGR valve

Slide lever back until it clicks, then separate.

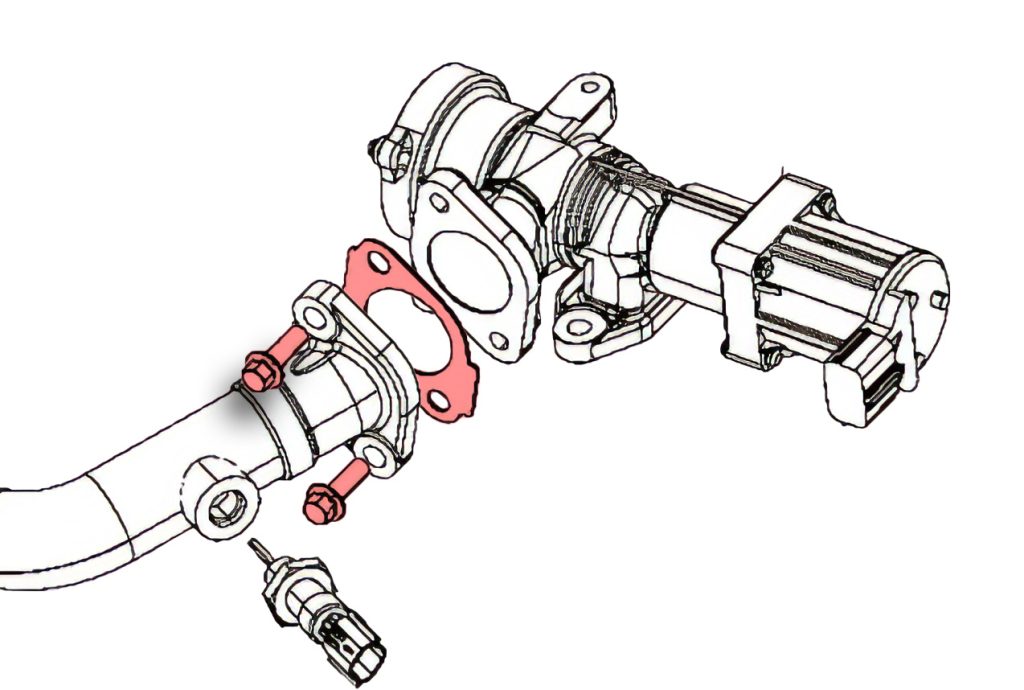

EGR Tube Removal

Note: Steps 19-25 refer to the Pickup Truck Style EGR with V-Band Clamps.

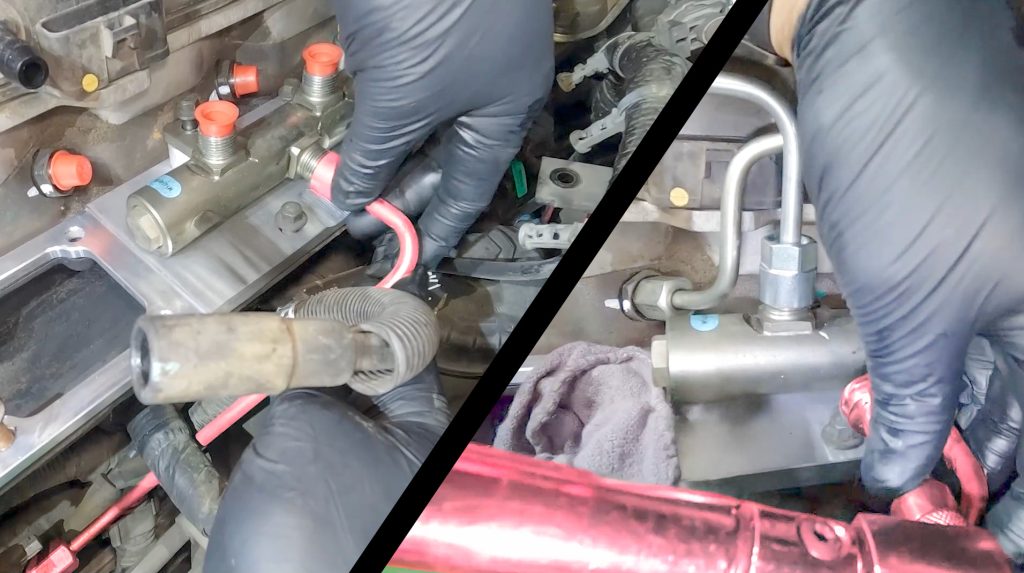

An amendment for the 2019+ Chassis Cab Bolted-On style EGR crossover tube is in the works.

19. Remove screw in EGR temp sensor from EGR crossover tube.

This sensor will be reused later with the Banks driver side crossover tube.

20. Loosen and remove EGR bolts and gasket on driver’s side

New 2 Bolt Gaskets are provided, put the EGR bolts aside as they will be reused.

21. EGR on passenger side

Loosen and remove 2 bolts & gasket that hold EGR tube flange to the EGR cooler.

22. Remove EGR tube from the truck.

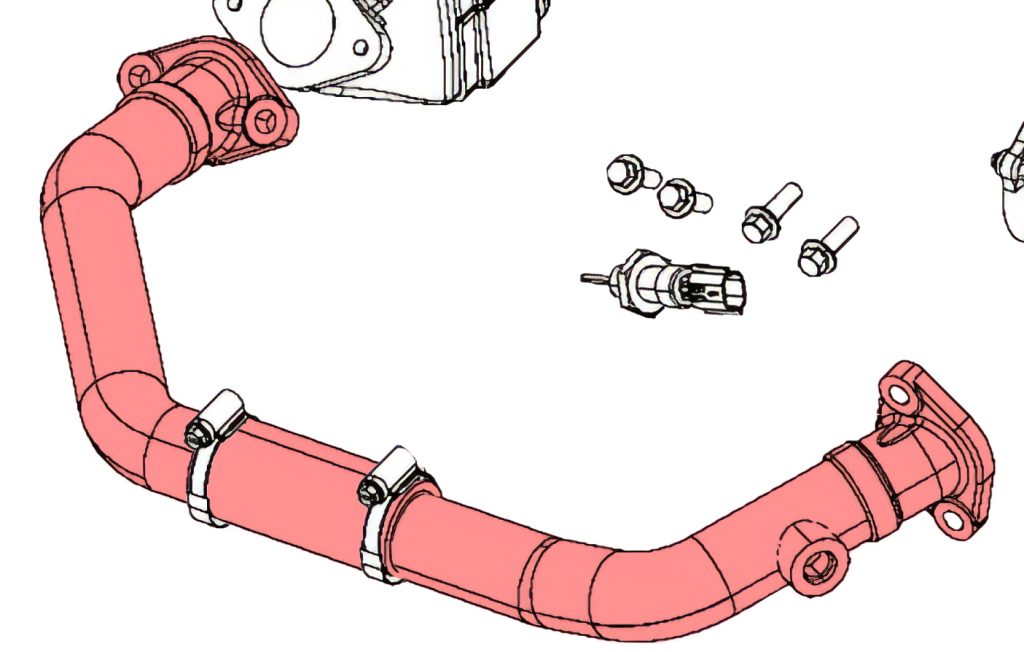

A Banks supplied Passenger and Driver side tube with silicone hose & clamps are provided for installation later in this guide.

Intake Elbow Removal

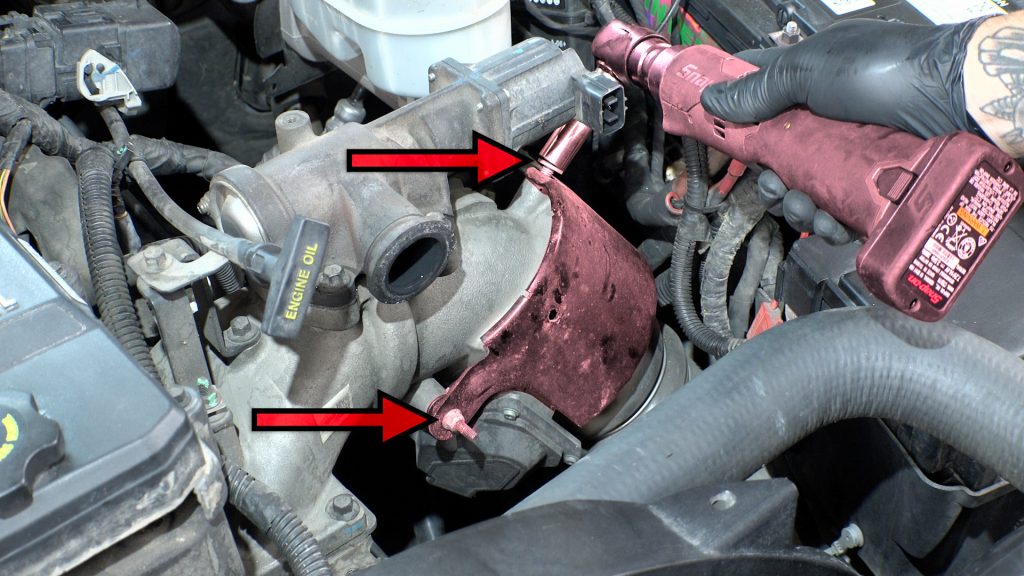

23. Remove throttle heat shield

24. Cut dip stick tube zip ties

Free up the thick 12V wire for the grid heater.

25. Remove 12 volt harness p-clamp

26. Remove heater cable from terminal

Relocate the wire out of the way once free.

27. Remove dipstick tube bracket

28. Bend tube up slightly

The Monster-Ram is slightly taller than the factory intake elbow; you’ll fine-tune this bend after the Monster-Ram is installed.

29. Loosen boost tube clamp

This does not have to be fully removed, just release tension on the hose

30. Pry boost tube hose off throttle body

The hose may feel stuck or glued to the throttle body; carefully walk a panel popper tool around the tube to loosen its grip on the throttle body. This will make removal later on easier.

31. Remove cable tie back of elbow and unplug MAP sensor

32. Remove forward PCV hose

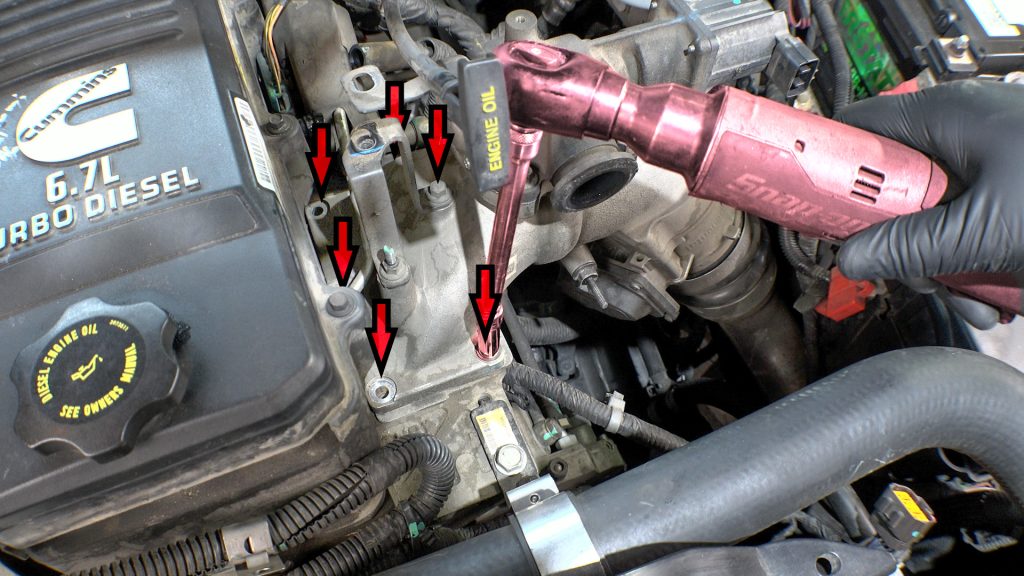

34. Remove 6 bolts on elbow

35. Lean elbow toward you & dislodge boost tube

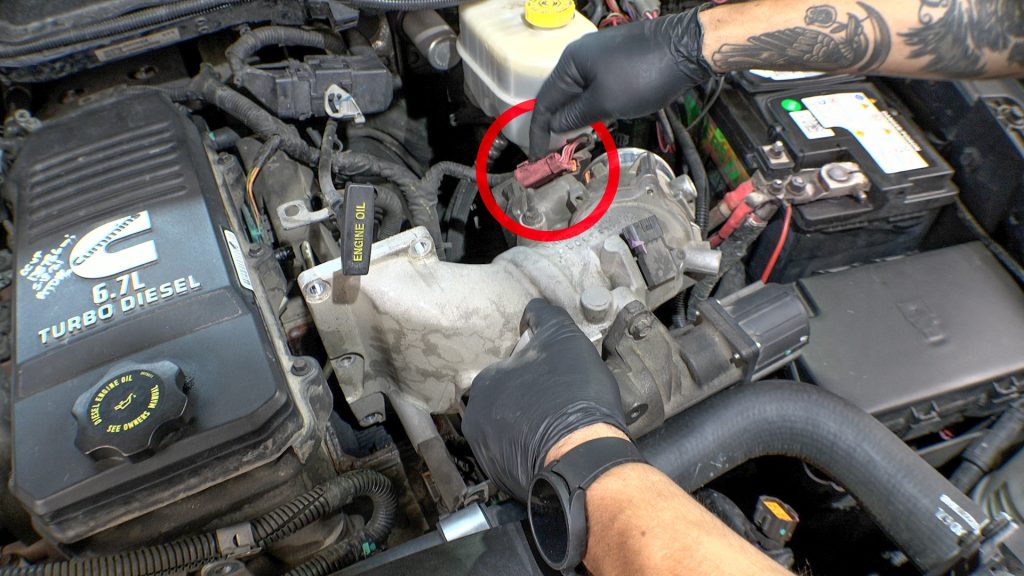

36. Remove throttle control plug

Now that the elbow has been twisted toward you, you can easily reach this plug.

Slide tab over to remove the plug, Depress the end, and pull to remove the plug.

37. Place rag and clamp over boost tube

Factory Heater Plate Removal

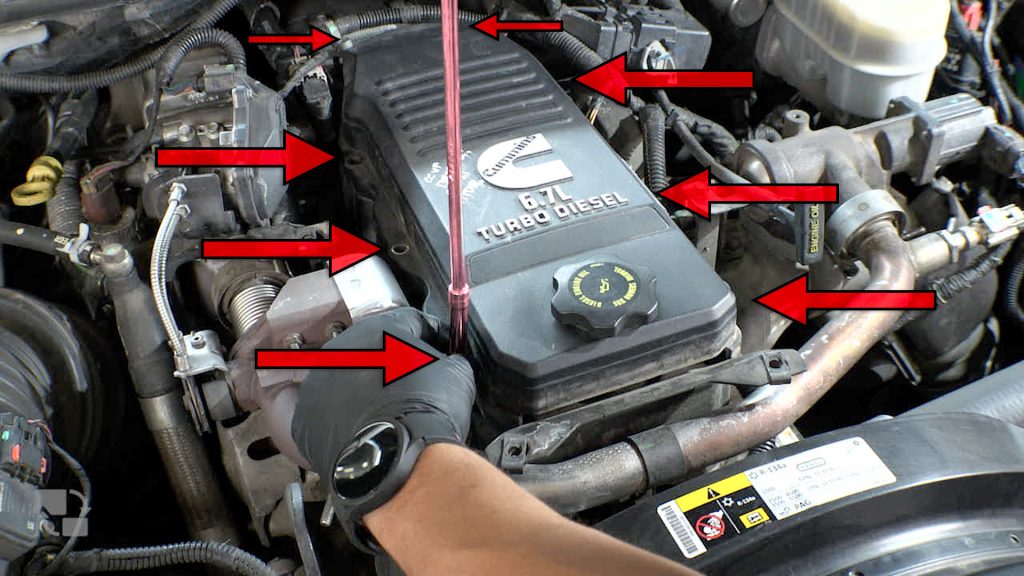

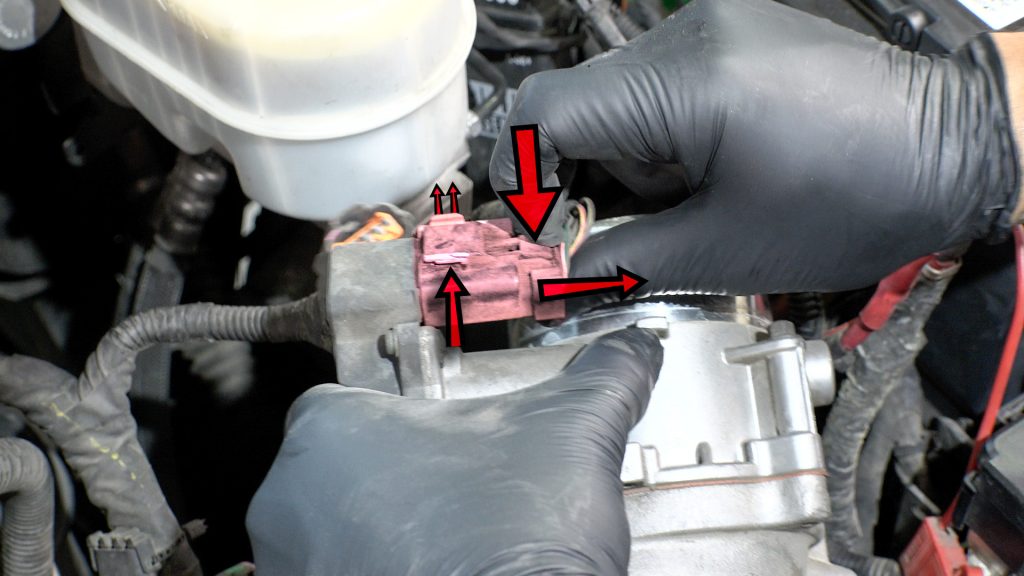

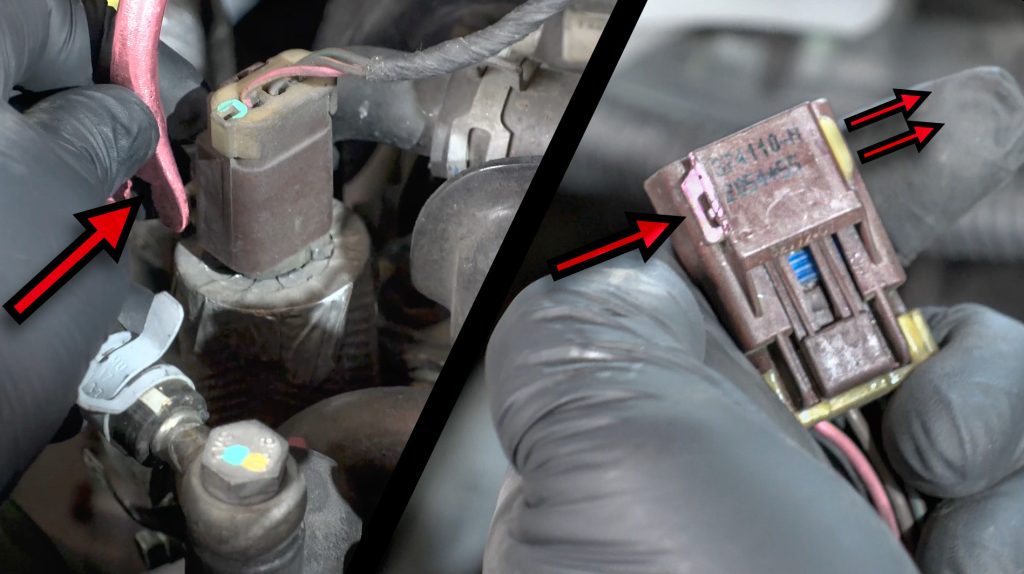

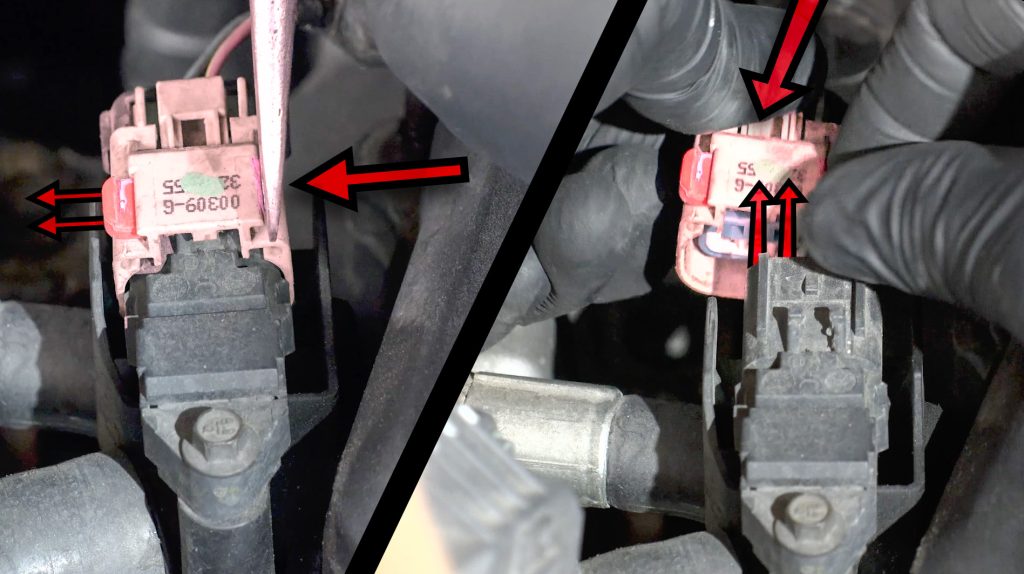

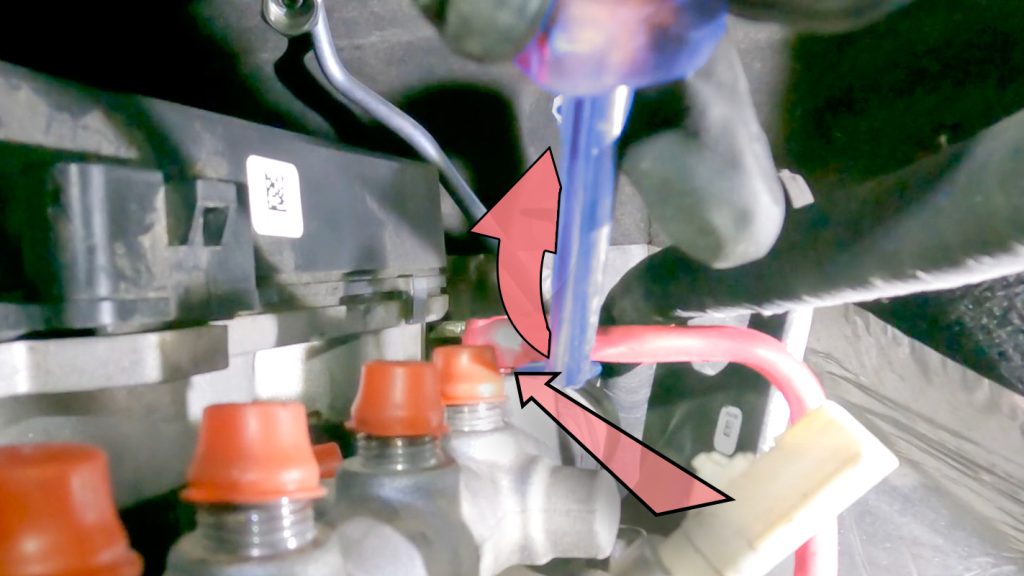

38. Disconnect first passenger side plug

39. Disconnect first passenger side plug

40. Disconnect second passenger side plug

Slide Lock In

Depress button to release clip

41. Disconnect third passenger side plug

42. disconnect third passenger side plug

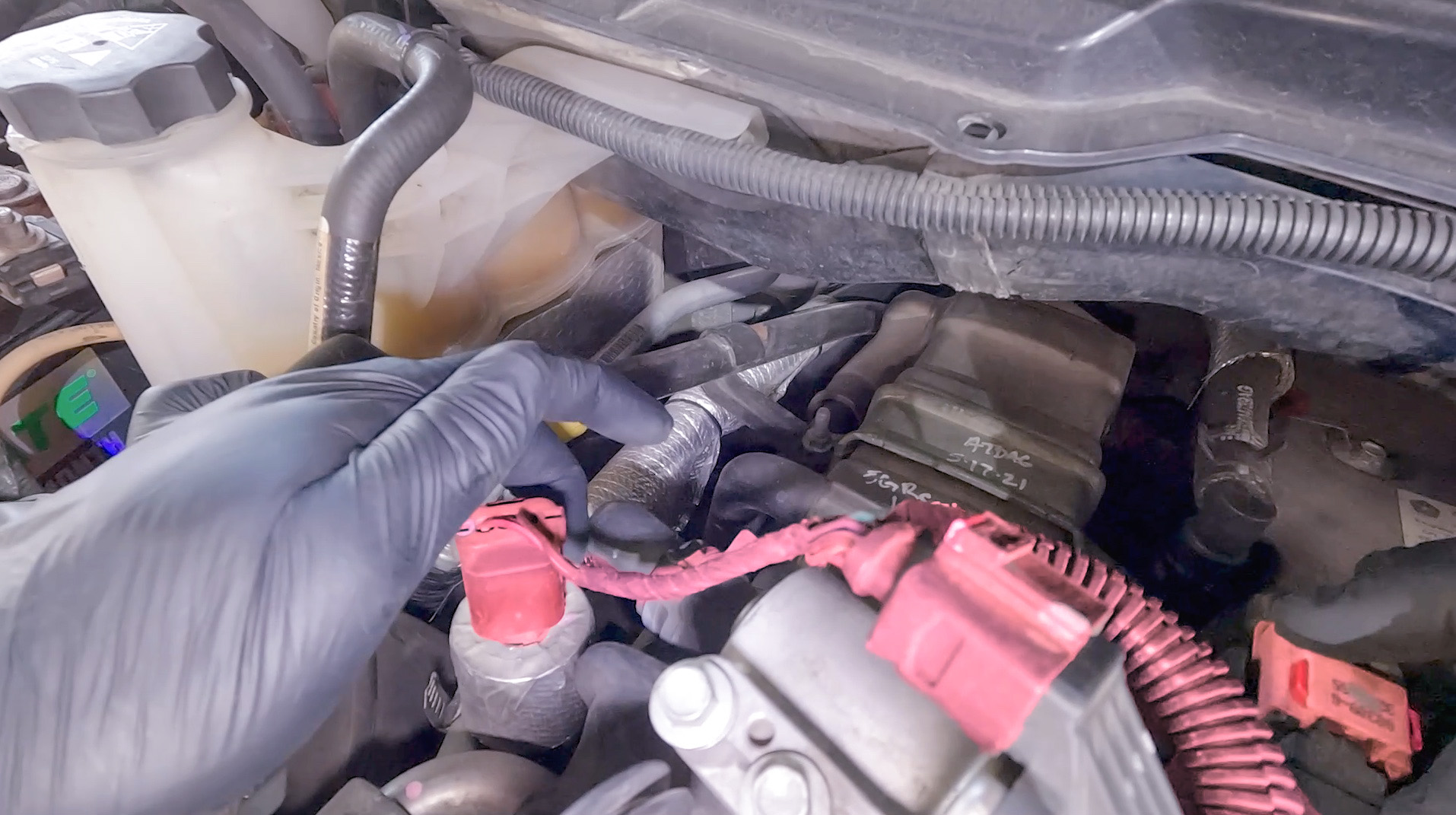

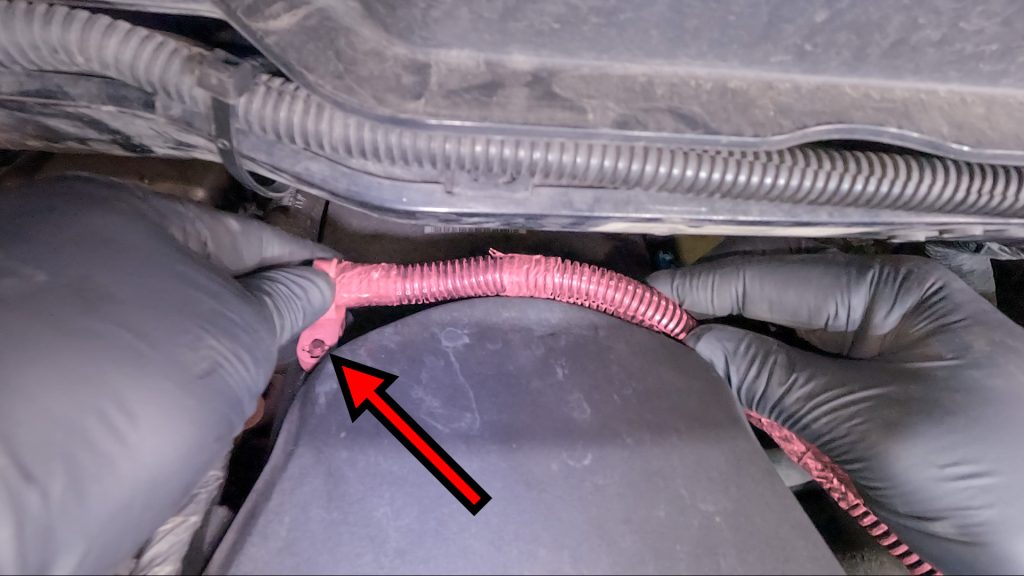

Slide the pink locking tab over, then pull to release.

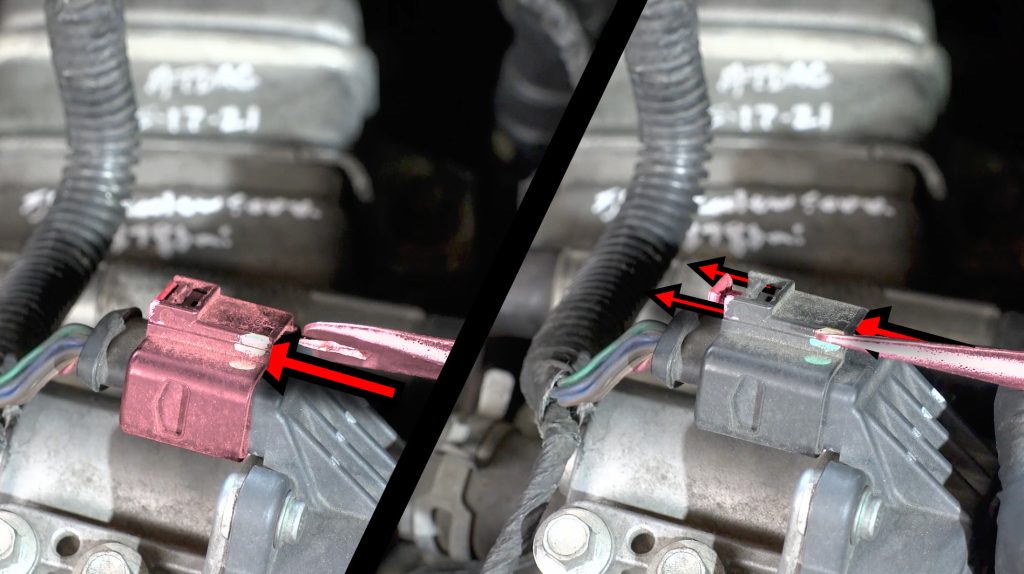

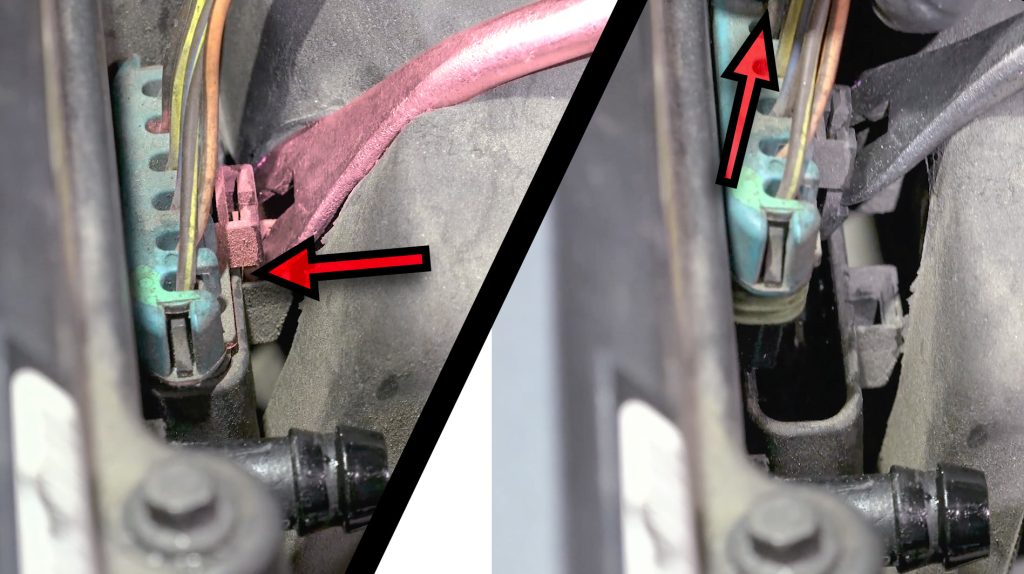

43. Disconnect flat blue driver side plug

43a. Press in the clip with a flat tool, and pull up.

44. Disconnect large driver side engine harness

Depress clip and fully rotate the white lock, then pull to disengage. May need some force due to dust, grime, etc.

Release cable tie

45. Remove rear driver side plug

46. Remove rear driver side flat blue plug

47. Remove rear PCV hose

48. Remove rubber isolator

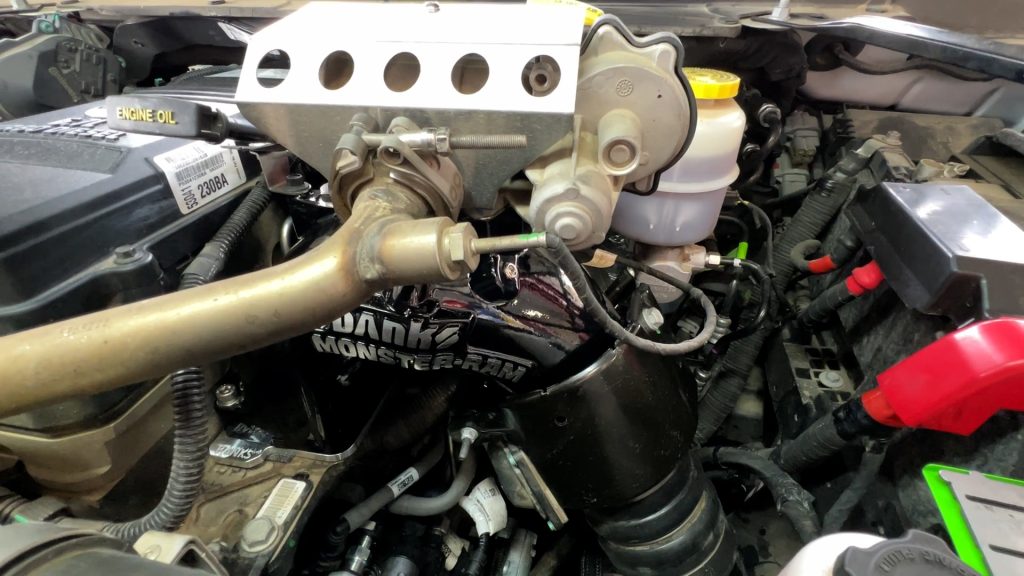

49. Remove cable ties from driver side studs

50. Remove dipstick tube stud

51. Bungee cord the dipstick tube

52. Place rag over intake

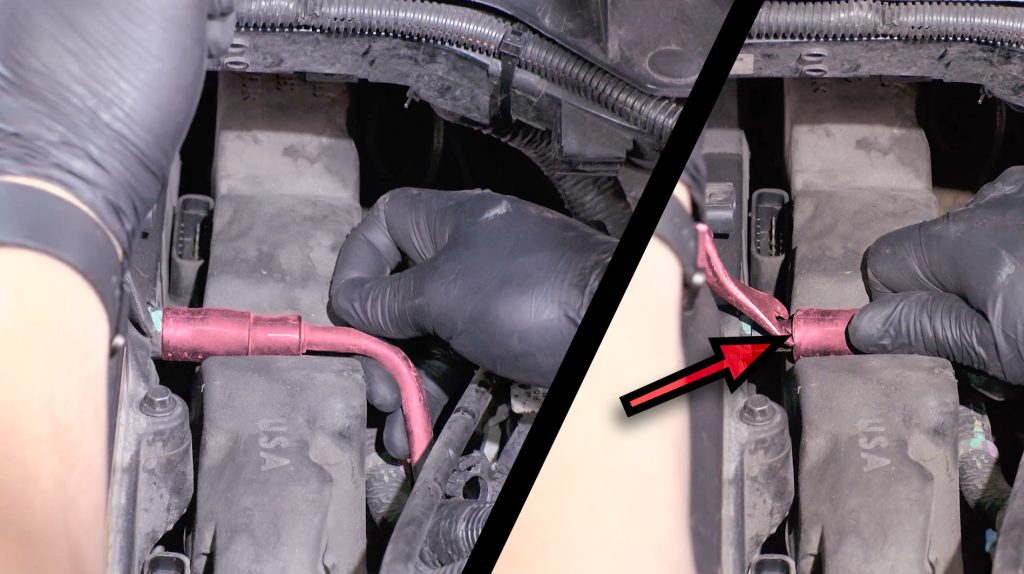

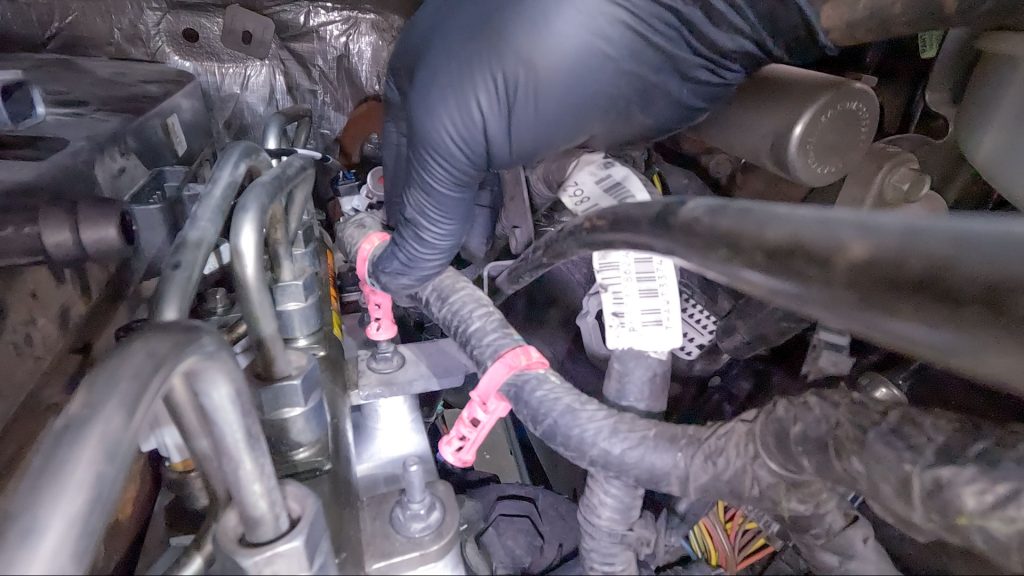

53. Remove fuel lines

If the inserts in the head start to move, use an open ended wrench to hold them inlace.

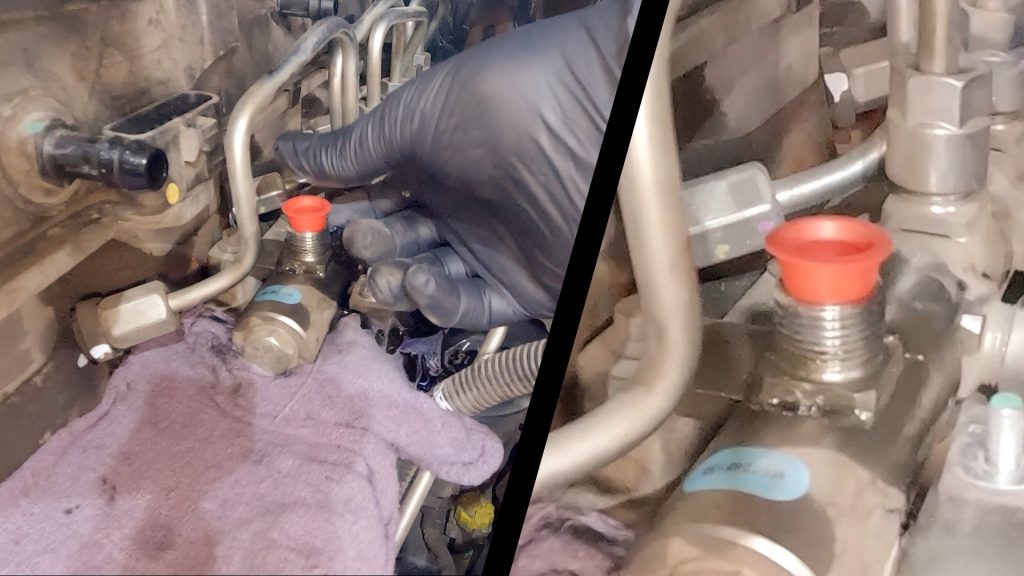

54. Install dust covers

Insert the covers, open end facing out. The caps should fit (inside) each blocked port.

55. Loosen #6 duel line and rotate out of way

Do not fully remove the rear fuel rail. It is difficult to reach and only needs to be moved out of the way as shown.

56. Loosen high pressure fuel feed line

Both the upper and lower ends

57. Swivel back high pressure fuel feed Line

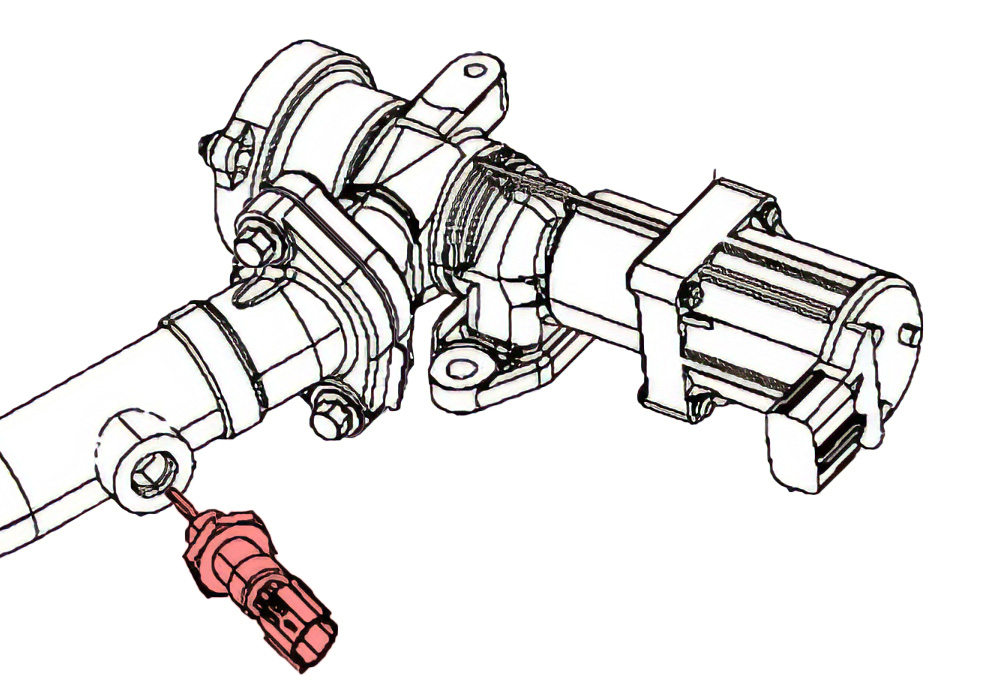

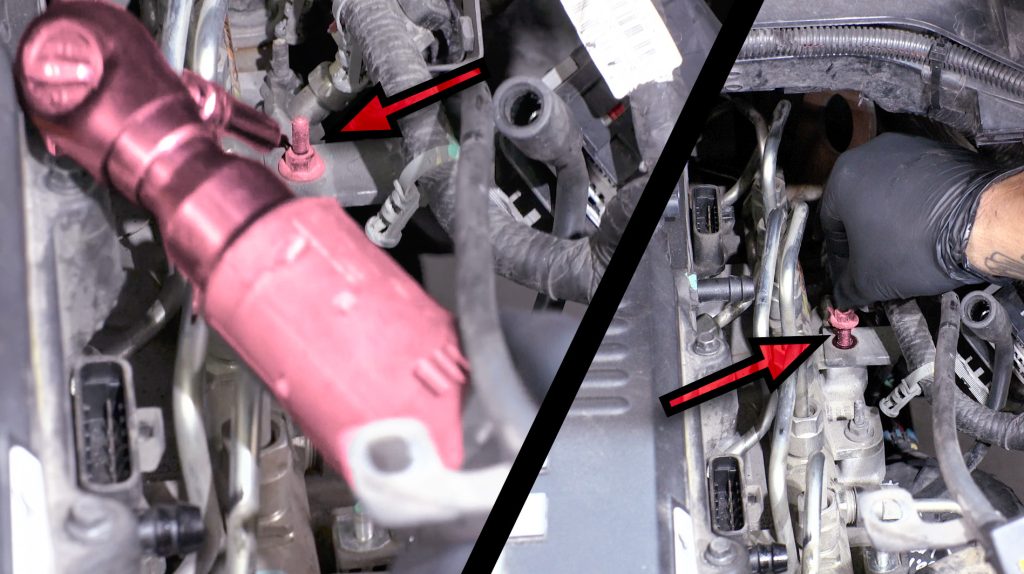

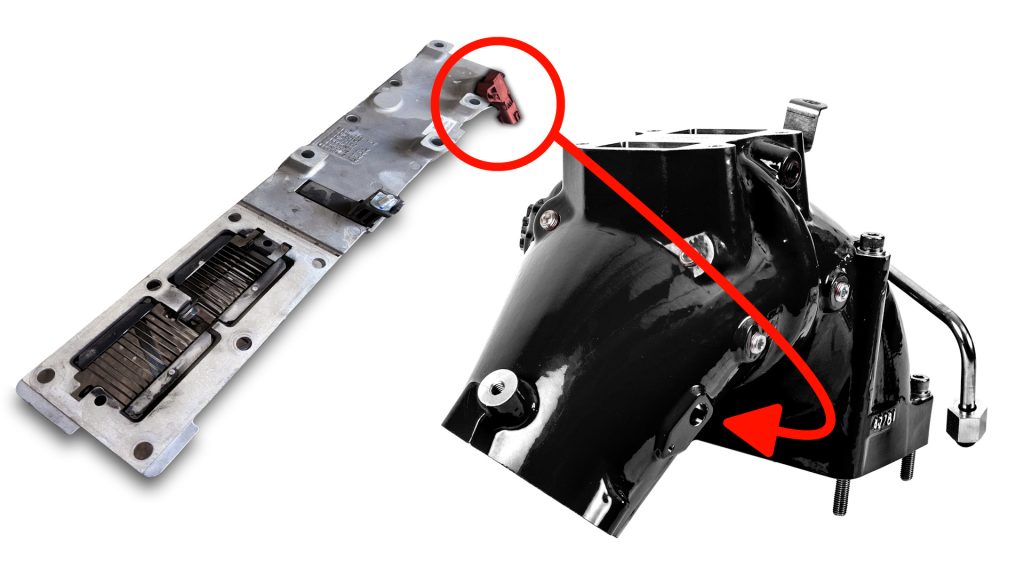

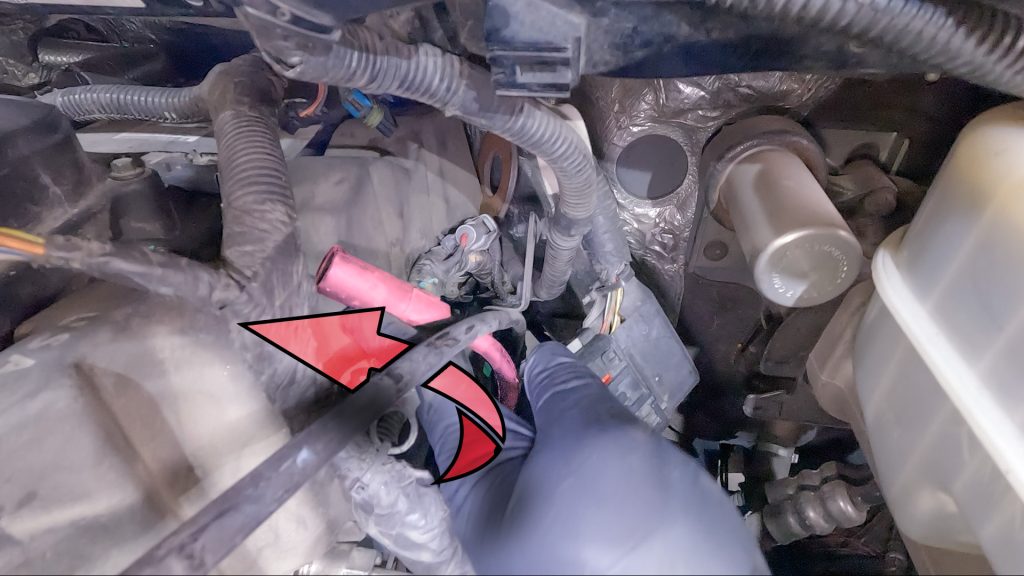

58. Rear sensor removal

Locate the rear thermocouple. Remove its black plastic cover by prying up & away from the sensor body.

Once the cap is removed, press the small red locking tab in, then unplug the sensor.

59. Loosen rear fuel line

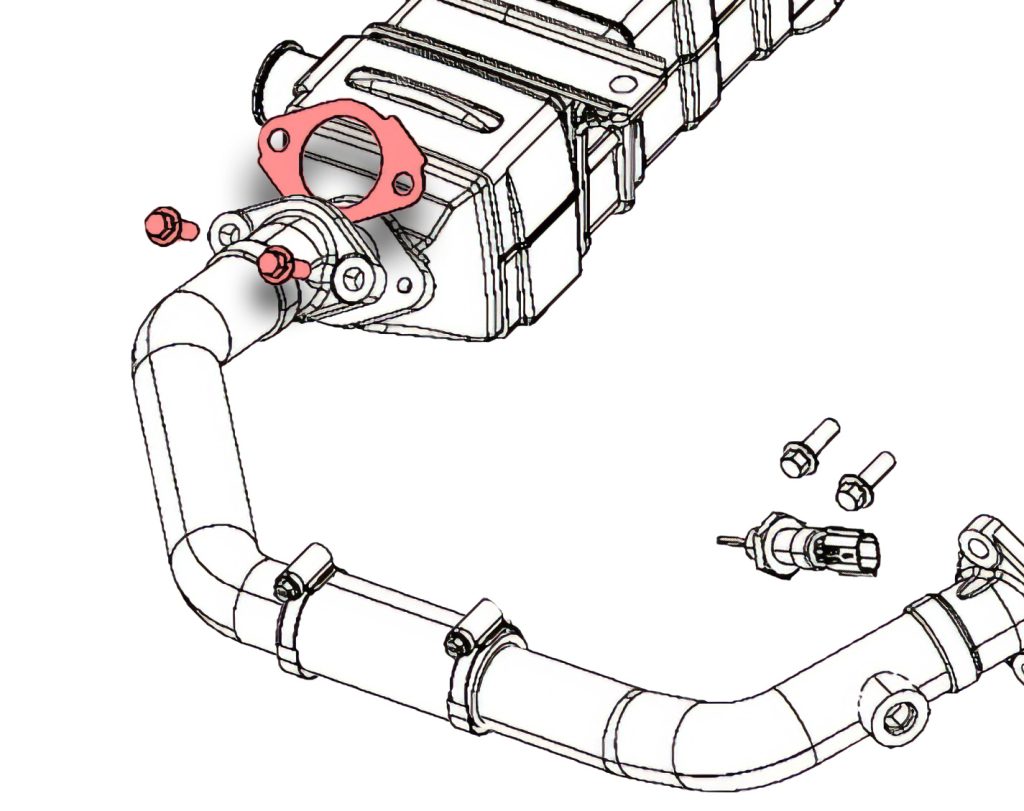

Note: There is a washer between the fuel rail and fuel line. Take care not to lose it when removing the banjo bolt.

Carefully remove the banjo bolt from the fitting.

The hard line does not have to be fully removed. Carefully pry the fuel line up just a hair, and slide the washer out with a screw driver.

Don’t lose this washer.

60. Remove fuel rail bolts

61. Place rag at the rear of fuel rail

There will still be fuel in the rail, and it’ll leak out in the next step if you don’t do this.

62. Bungee fuel rail

Be sure that rag stays at the rear of the fuel rail, it will leak when you tilt it back.

63. Remove factory grid heater

64. Clean manifold surface

Take care not to scratch the surface, and vacuum out any debris that fall into the manifold.

A rag with some solvent can clean up the finer material.

Be certain there is no rust buildup. Rust or an uneven surface will result in an air leak.

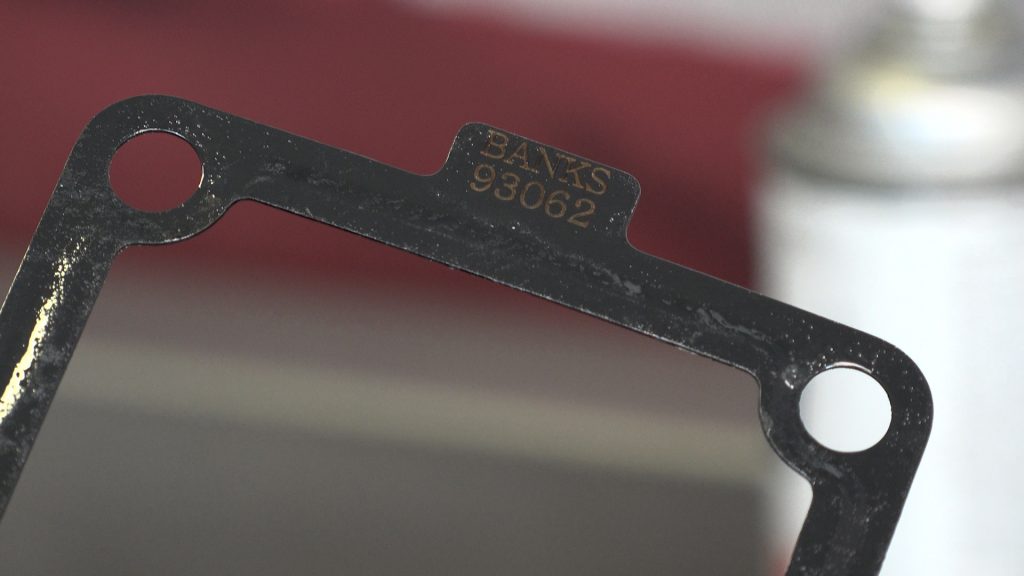

65. Spray adhesive to gasket (Banks side)

Side that says Banks, should be the side with the adhesive. Let it sit for about 3 min for the glue to tack up.

66. Align gasket and stick on

Line up all of the bolt holes, and stick the gasket to the flat side of the billet plate.

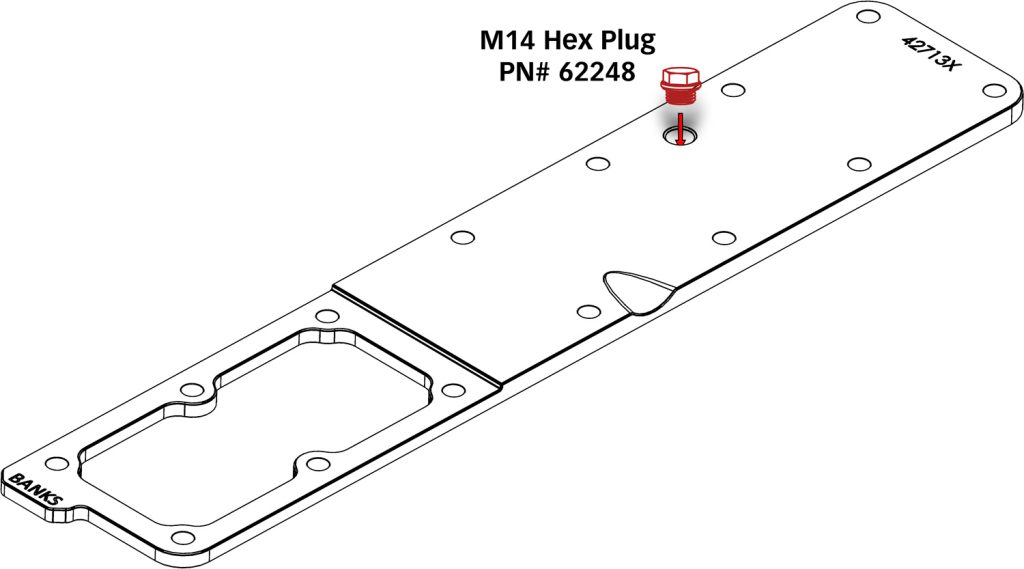

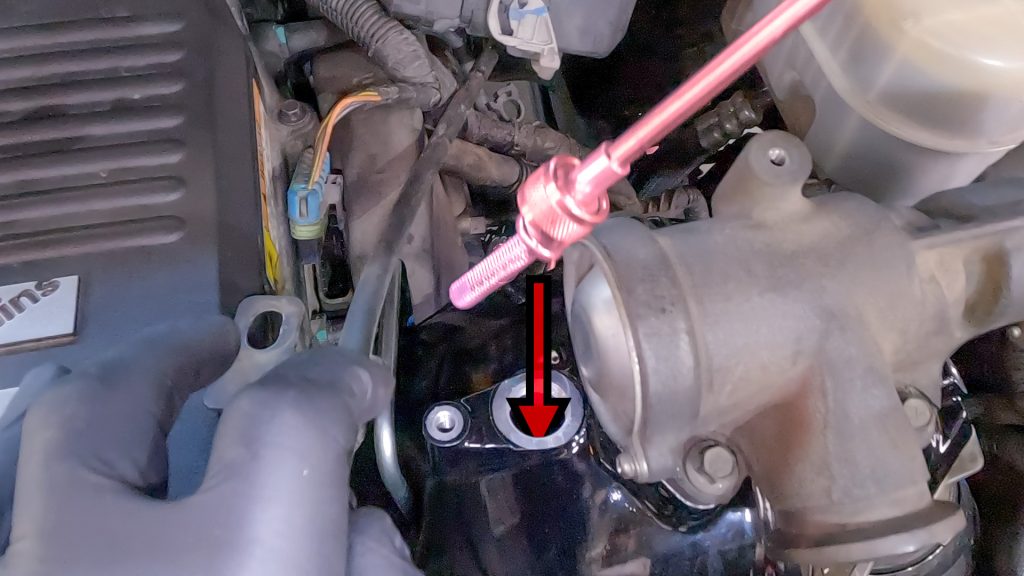

67. Note: M14 plug (62248)

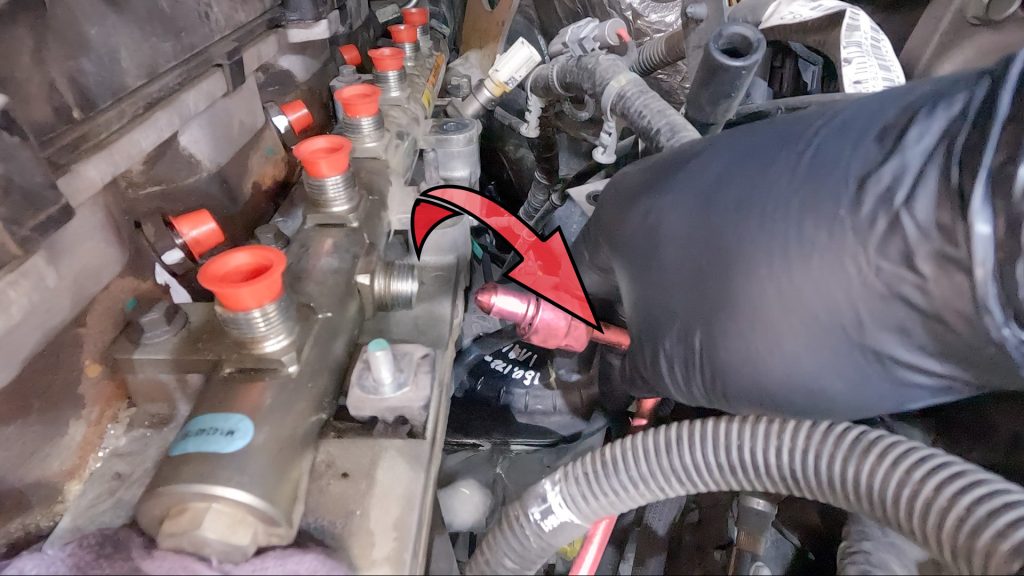

Chassis Cab: Depending on the vehicle production date or GVWR a thermocouple temp sensor may be mounted on the Manifold Plate.

If your vehicle was equipped this way, transfer the sensor into the Banks Billet Plate.

If your vehicle was not equipped this way. Plug the billet plate with with the M14 Plug

Don’t over-tighten the sensor into the billet plate as the aluminum is softer than the steel threads on the sensor. It will bottom out so you’ll know when to stop.

Installation of Monster-Ram

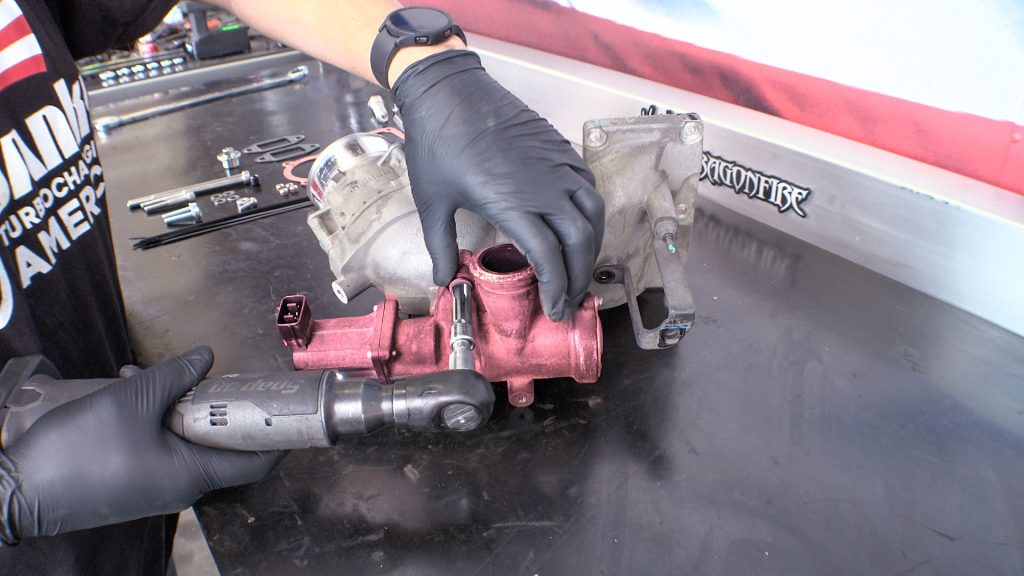

68. Remove EGR valve

69. Remove throttle body

The throttle will be stuck onto the gasket, so use a rubber mallet to help tap it free from the elbow.

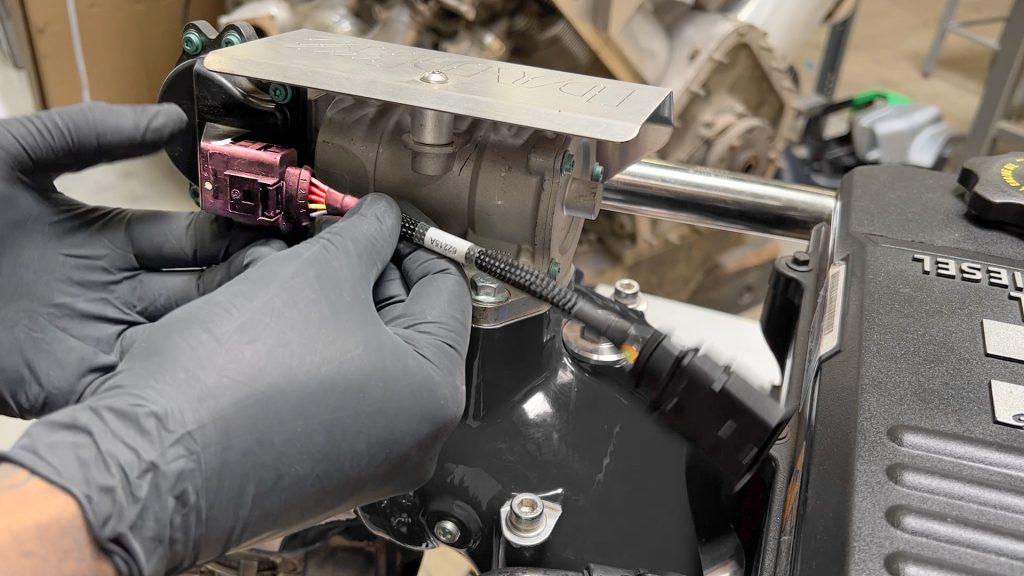

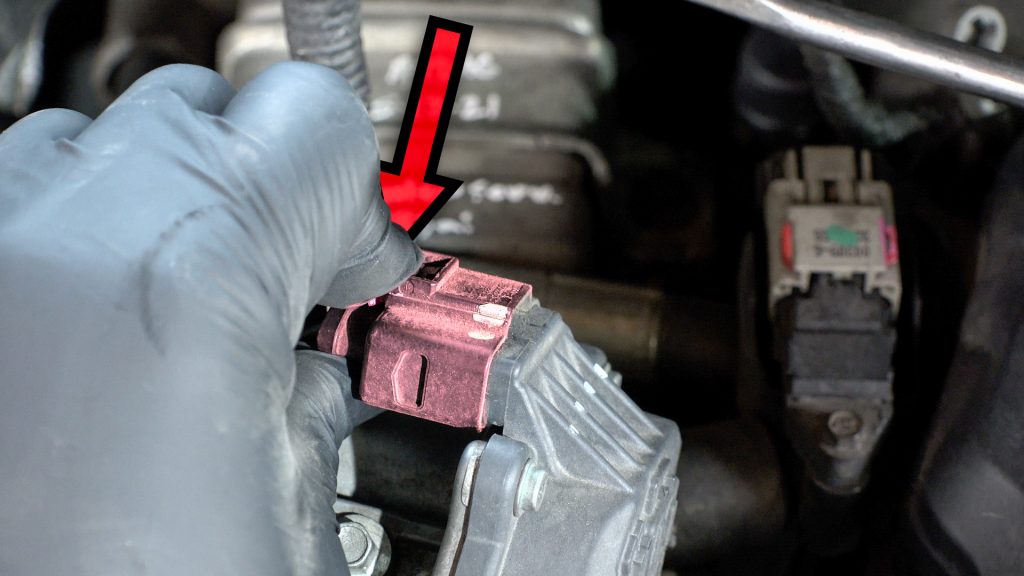

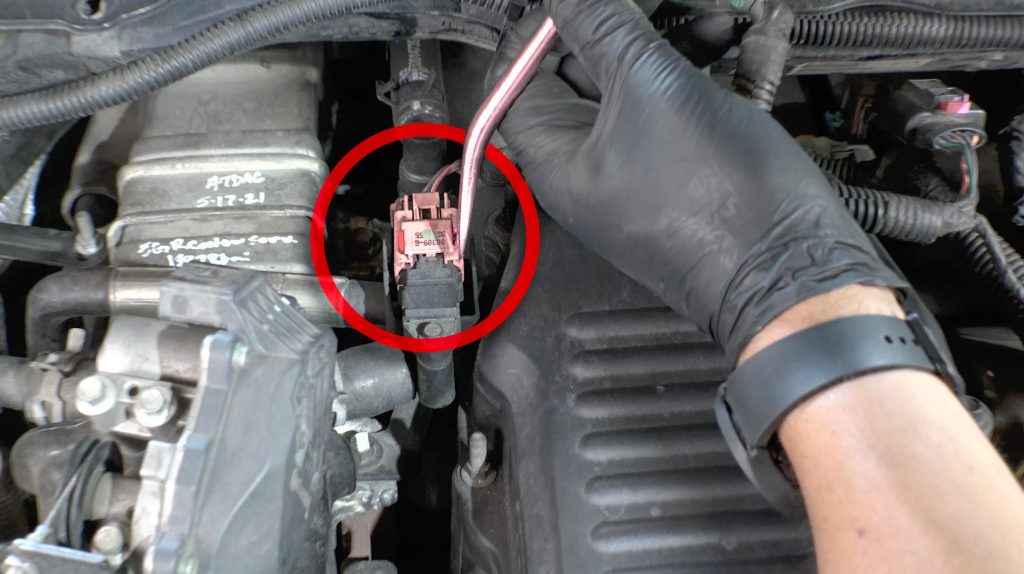

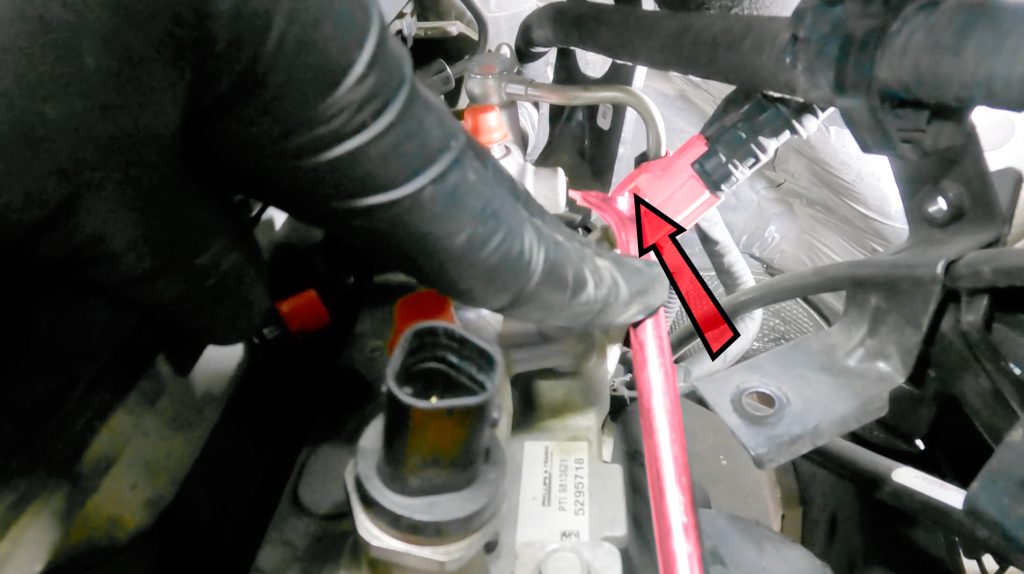

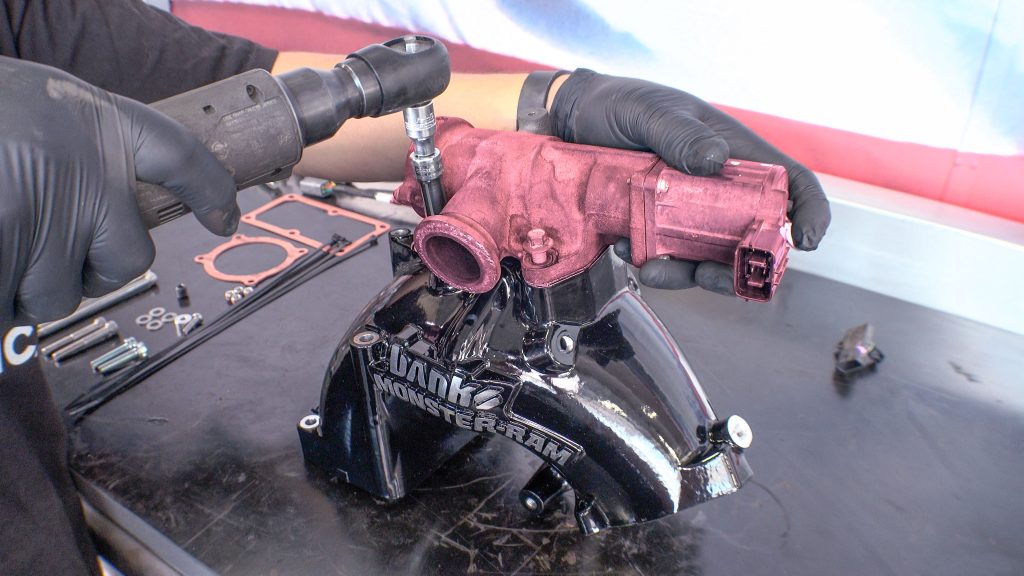

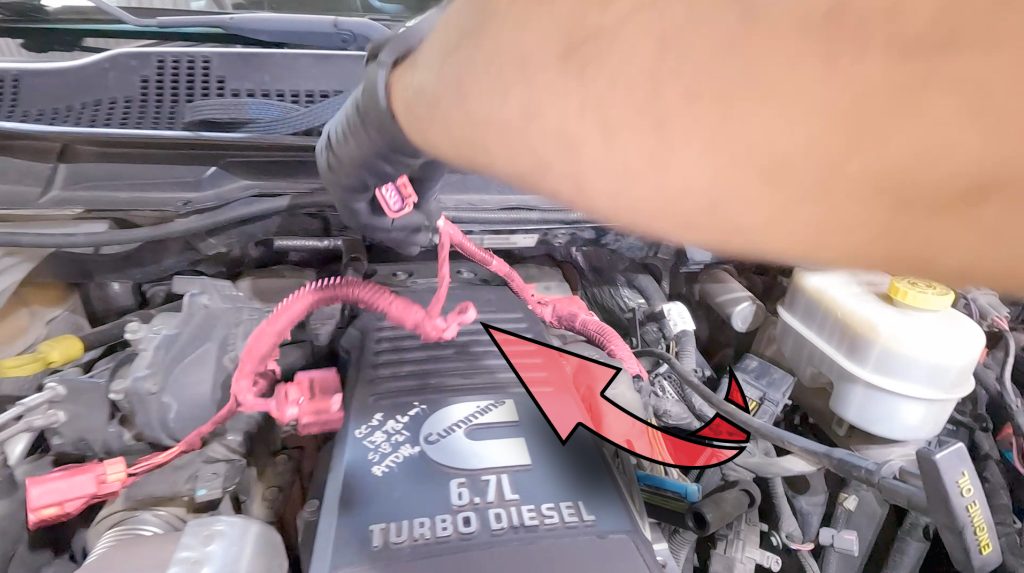

70. Chassis-cab: MAP sensor

The Chassis-Cab MAP sensor is located on the rear of the intake manifold.

This sensor will be transferred to the MAP sensor provision on the Banks Monster-Ram.

71. Remove and transfer elbow stud

72. Clean EGR gasket surface

Take care not to nick the surface. Do the same for the throttle body gasket mating surface.

73. Place new EGR gaskets on monster-ram

74. Fasten EGR bolts

Apply a small amount of medium strength thread locker and tighten to 18 ft/lbs.

75. Align throttle body gasket

76. Fasten throttle body to Monster-Ram

The 1/8” NPT ports shall only be used for installing sensors for measuring air temperature, pressure, or flow. Sensors installed to these ports shall have a fitting of 1/8” NPT and shall not be connected to the vehicle’s electronic control units. In addition, factory sensors that come equipped on the vehicle shall not be disconnected and shall not be relocated to the ports. The ports, when not used, shall be closed off with the supplied plugs.

77. Install sensor plugs

Inspect the threaded holes, and be sure there is no powder coat in the holes.

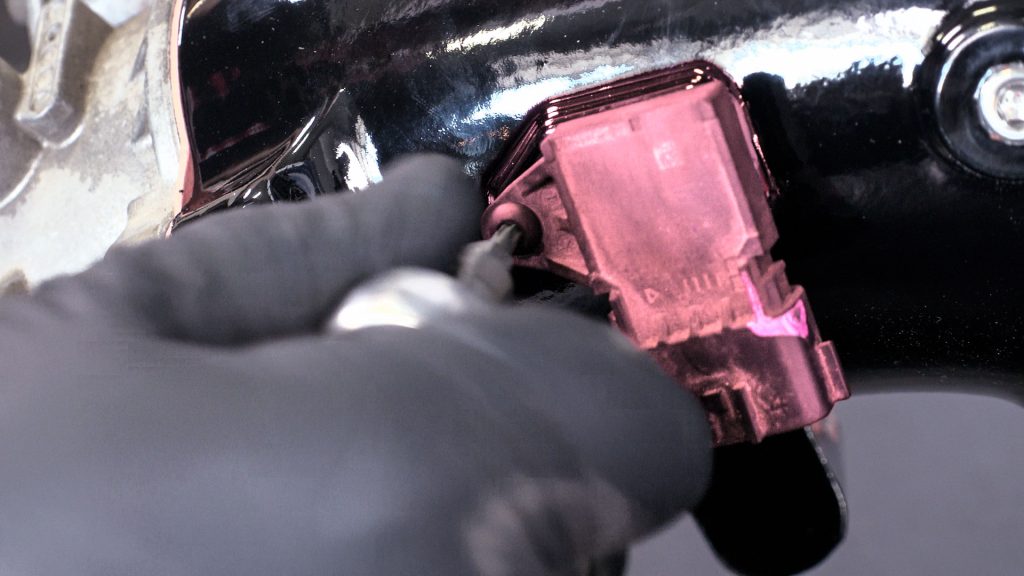

78. Rear temp sensor.

Chassis Cab: Depending on the vehicle production date or GVWR your EGR sensor may be mounted on the rear of the Monster-Ram.

If your vehicle was not equipped this way. Plug the rear EGR port with the M12 plug with some blue Loctite.

79. Install MAP sensor

Now is a good time to clean the sensor with some MAF/MAP cleaner spray.

80. Spray gasket with adhesive

81. Place washers on the hex cap screws, then apply some blue threadlocker as you install them

82. Use a stock bolt to hold billet plate in place

83. Place fuel rail standoffs

If your kit includes the cast aluminum plate (42731), these standoffs will not be included, and this step can be skipped.

84. Release bungee cord. place fuel rail and studs in place

85. Tighten Fuel Rail

Torque bolts to 18-20 ft/lbs

86. Re-Install temp sensor. hand tighten washer and banjo bolt

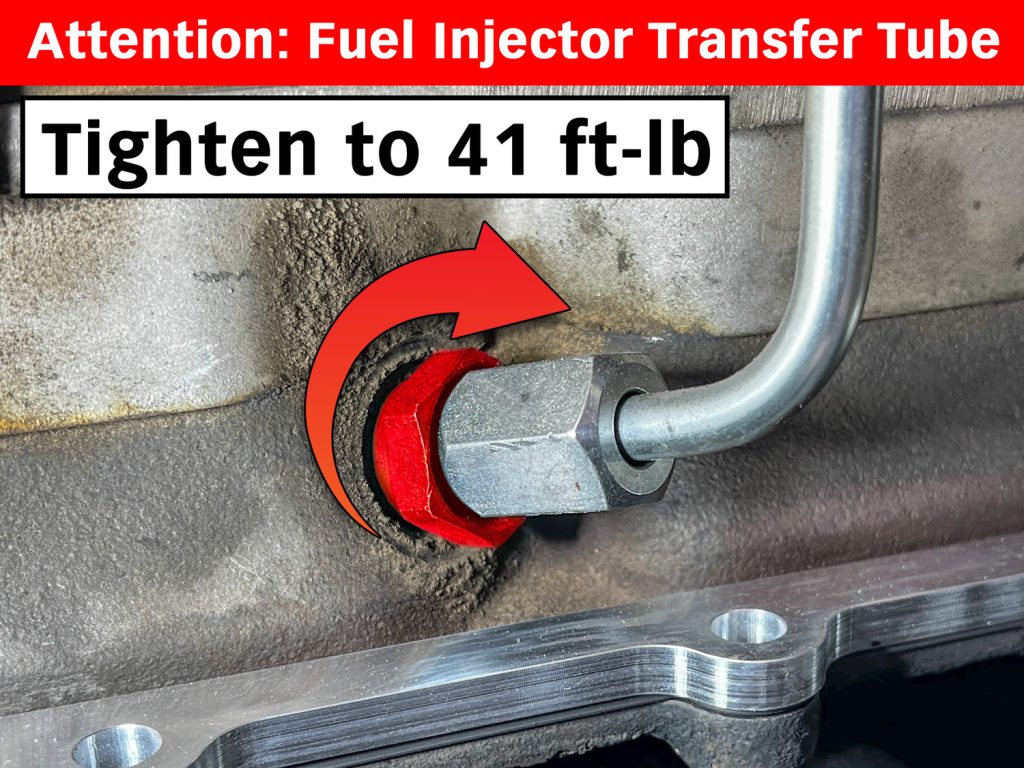

Attention:

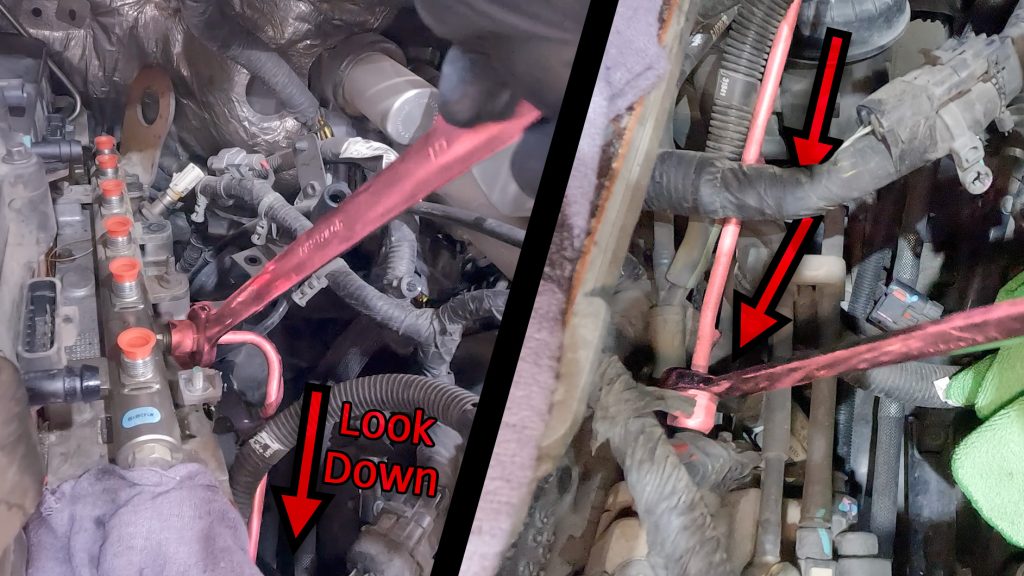

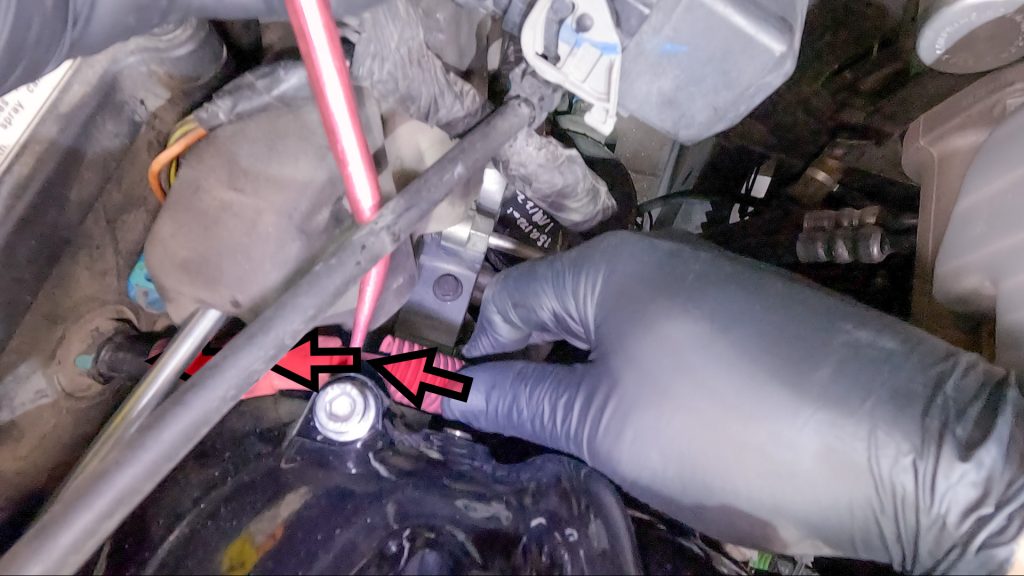

Due to age and vibration, over time the fuel injector transfer tube that the fuel lines thread into can back out and loosen.

Check that each of the 6 transfer tubes are torqued to 41 ft/lb before reinstalling the fuel lines

87. Tighten fuel lines to 41 ft/lbs

88. Tighten fuel feed line to 41 ft/lb

89. Connect temp sensor extension harness.

Be sure to lock the plug once connected.

90. Remove middle right stud for dipstick tube

Slide dipstick bracket over and reinstall stud

91. Push engine harness cable ties back onto studs

92. Put rubber isolator back into place

93. Run rear PCV hose under dipstick tube

94. Connect rear PCV hose back to valve cover

95. Connect rear flat blue injector plug

96. Connect rear white plug

Be sure to slide the pink lock back into position.

97. Route engine harness under dipstick and around valve cover

97a. Plug In 3 remaining plugs

98. Push cable ties onto studs

99. Reconnect engine harness connector

100. Do not connect front blue injector plug yet

101. Remove rag from boost tube, put the clamp back on

102. Insert Monster-Ram into boost tube

103. Put long bolt into front corner by hand

This will help hold the Monster-Ram inlace. Then do the same for the long bolt on the backside. Followed by the two smaller bolts.

104. Use telescoping magnet to start bolts in the middle of the Monster-Ram

This is useful for the small bolt in the middle, which is hard to reach, and mandatory for the one that goes through the top coil heater hole. Use Medium-strength liquid thread locker!

Use hex key extension to tighten bolt

Tighten all 6 bolts 18-20 ft/lbs

Start with the bolt that’s inside the Monster-Ram, then work in a cross pattern to torque to spec.

105. Slide copper washer onto heater coil

106. Tighten coil heater by hand

Should be tight, but don’t over do it.

107. Install dipstick tube bracket

108. Now install forward flat blue injector plug

Be sure it clicks.

109. Connect forward PCV hose to valve cover

This is a tight fit, but doable. Wiggle the rubber hose on the nipple a quarter inch, then use a pry tool as a lever to help slide it on.

110. Plug in MAP sensor (rear of Monster-Ram)

Secure the slide lock back into position.

111. Plug in throttle plug

Secure the slide lock back into position.

112. Tighten boost tube clamp

113. Remove and discard 12v heater cable p-clamp

Apply a drop of red thread locker, then spin the nut back 3 or 4 threads from the bottom of the stud.

114. Assemble heater cable extension bracket

2019+ Rams have a permanently attached nut to the OEM heater harness.

Use the supplied adapter and M8 bolt to adapt your 2019+ OEM heater harness. The adapter should be oriented so the bolt is facing up with the nut on top. Use thread locker.

115. Apply heat shrink

The heat shrink must cover the bolted area to prevent any accidental metal-to-metal content. Leave only the new bolt hole exposed.

This is to prevent the possibility of the 12V wire touching any part of the body and causing a short. The heat shrink is thick and will take a moment to start shrinking.

116. Place heater cable onto threaded post

The head of the M6 Bolt you just covered needs to face down.

117. Use two wrenches to hold the bottom nut from turning

Be sure to support the lower nut with an open head wrench. You don’t want to break the stud off while tightening the top nut.

118. Be sure lower bolt is away from metal

No part of the 12V cable can touch the body of the coil heater. Otherwise it will arc, melt, and fail.

119. Install new banks EGR crossover tube with new 2 bolt gaskets.

Leave the top bolt of the driver-side flange off for now.

120. The banks silicone hose goes in the middle. Use the supplied constant tension clamps.

121. Line up banks EGR tube with EGR valve.

122. Bolt on EGR tube with banks EGR cover.

Thread back in the EGR temp sensor from the OEM crossover pipe if you haven’t done so yet.

123. Place rear eatshield spacer and screw

Use a drop of thread locker on the screw to prevent it from vibrating out.

124. Tighten torx head screw

125. Install throttle heat shield bolt and nuts

126. Connect temp sensor extension and MAP extension

127. Connect rear EGR extension & harness

128. Reconnect batteries

129. First start may take 1-2min of engine turnover.

This is normal. The fuel system, rail, and lines need to re-pressurize.

130. Check for leaks.

Check that all harnesses and components are free of moving parts. Check for any leaks while the engine is running. Head out for a short test drive, and double-check for leaks one more time..

CARB EO Label

For smog check purposes, affix the CARB E.O. Label on a visible location under the hood. Banks recommends using the radiator shroud location