Testing That Goes Beyond Performance

Just about anyone can make an engine and call it a “performance” or a “racing” engine. In the old days you’d see magazines with glossy pictures and headlines touting really big numbers, but in today’s world you can actually see and hear an engine make big noise and see big power numbers on a screen. YouTube is filled with videos of engines and vehicles on a dyno making power. The operators crank it up till the power peaks and then immediately go back to idle because they made the number they liked. And yeah, that engine actually did make power… but for how long? If they were put to a test where they’d have to sustain hours at wide-open throttle would they even survive producing a lower amount of power? Banks has been building engines since the 60’s, so we know a thing or two about them. The engines we’ve been making all these years have always been built with endurance in mind, and in many cases that means something that would last an entire season with minimal upkeep. We also supply powerplants to the military, and those engines will see some of the most extreme conditions known to man. Conditions that require more than just seeing a power number.

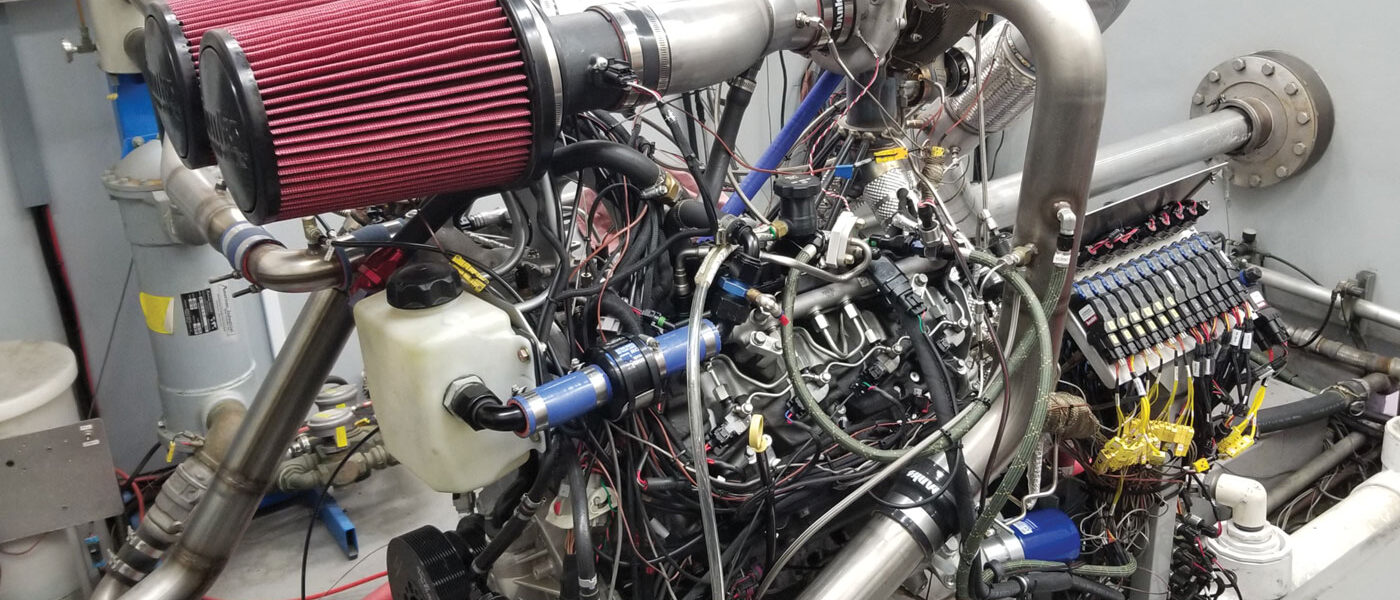

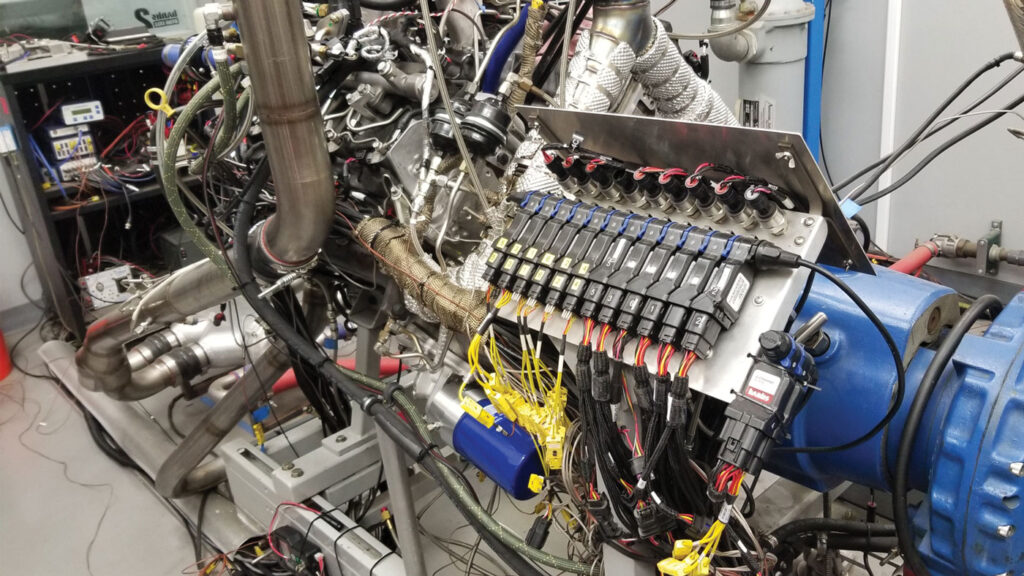

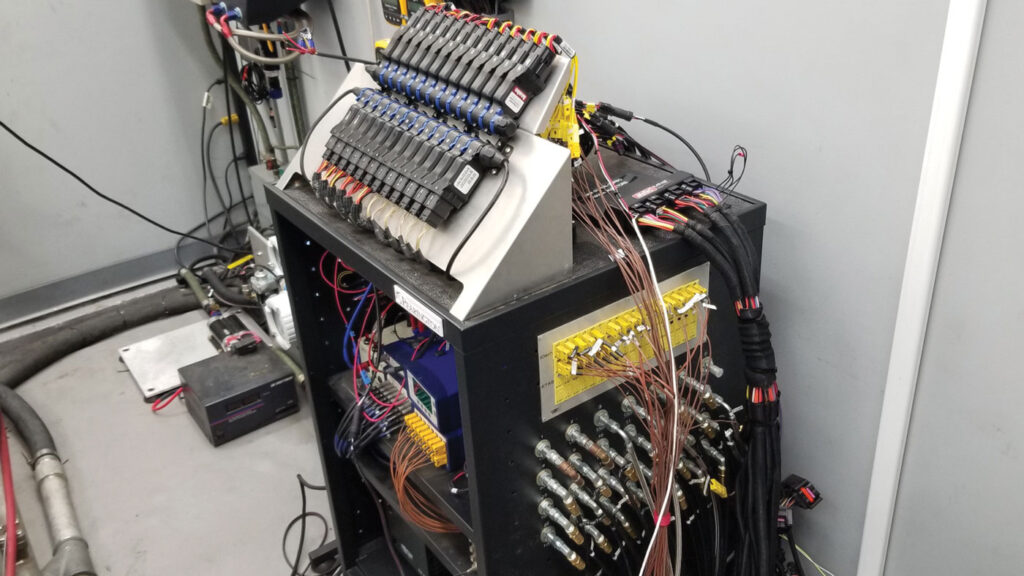

Let’s take a look at what testing goes into proving the build of an engine for the military Another division of Banks called Banks Tech works closely with military and defense contractors on a variety of diesel and other fuel-related projects, and is responsible for every engine that is being supplied to Oshkosh for use in the United States Military’s new Joint Light Tactical Vehicle (JLTV for short). Every engine that comes off of the assembly line from the engine build plant in Azusa, CA must be dyno checked before leaving. That one test, however, had many that tests that proceeded it. In order to produce an engine for the military means that it had to pass the NATO 400-hour or a “Double-NATO” test, which is actually the 400-test done twice consecutively. These tests must use all the fuel, lubricants and anti-freezes that NATO specifies for use in the whole military fleet. That means the engines must operate on the same fuel as a helicopter for instance, so fuel from straight from the corner gas station. One of the test parameters must have the smoke emissions measured throughout the entire run, and the recorded range can’t exceed a specific amount or it fails the test, so rolling coal isn’t an option.

The standard NATO endurance test duration is 400-hours, which is divided into four parts of 100 hours each. Each 100-hour period is made up of ten 10-hour segments, and at least five times during the 100 hours the engine needs to be shut down for a minimum of eight hours. At the end of each 100-hour period, normal maintenance and adjustments are permitted for the test engine, and the engine will be submitted to a full-load performance check. The double-NATO test is an insane 800-hour test that is basically, as its title implies, the 400-hour test done twice!

Here are the variable that must be monitored during the NATO test are:

Main Values:

• Speed (engine output shaft)

• Torque (engine output shaft)

• Temperature of ambient air

• Atmospheric pressure

• Humidity

Air and Gases:

• Inlet air temperature

• Inlet or cylinder inlet depression

• Air temperature and pressure in the inlet manifold

• Exhaust temperature

• Exhaust back pressure

Lubrication and Cooling:

• Oil temperatures and pressures

• Coolant temperatures into and out of the engine

• Flow rates of fluids to cooling devices external to the engine

• Oil consumption

Fuel:

• Fuel temperature

• Fuel consumption

Miscellaneous

• Blow-by

• Smoke density

• Exhaust gasses analysis

| The standard NATO endurance test duration is 400-hours, which is these brutal tests are at max load, wide-open throttle, and truly push engines to their limits. Banks has been continued to produce engines that meet and exceed these NATO tests for many years, and it is a testament to their ability to produce durable engines approved for use in the military. Throughout the test, the engine must keep on making at least 95% of the initial measured power. If something happens where the engine dips below that amount and can’t be fixed with normal maintenance or adjustments it’s considered a “minor failure”, everything done to try to fix it must be reported, and the test will be terminated and must start at zero hours. A “major failure” is where there’s any parts failure that stops the engine or causes a loss of power where that 95% can’t be reached with normal maintenance or adjustments. This failure also has to be recorded, as well as anything that was tried to get the engine back on track, and you guessed it… the clock goes back to zero. That means that if even if you’re at hour 395 on the test and the engine can’t produce at least 95% or the initial power numbers that the test has to be stopped, and you’d have to start all over again from the very beginning. |

Now let’s talk testing accuracy that’s required. We’re not going to go totally into it, but here are some of the measurements that need to be recorded:

Output speed: must be accurate within +/- 0.5%

Torque: must be accurate within +/- 0.5%

Fuel consumption: +/- 1%

Temperature: intake air +/- 1 degree C

Atmospheric pressure: +/- 0.7 mbar

Air and gas pressure: +/- 50 mbar

Induction and exhaust pressure and depression: +/- 0.250 mbar

Fluid pressure: +/- 0.250 mbar

Building a true performance/endurance engine take a lot, especially if it’s for the military, but it’s something Banks has done for several decades. It’s not a ramp on the throttle to get a momentary power number and call it good like what happens on the usual YouTube videos. There is no “pass go” card. No fudge factor. It’s recorded and repeated science. This is engine building at its most serious, and it’s power that can saves lives under just about any condition.