Performance Odyssey

PowerBoat July 1979

Can you put a turbo’d V6 in a boat? That was the question General Motors asked Gale Banks … you can guess his answer!

For the last several years, one commonly accepted source of compact, smooth, lightweight power for marine applications has been the turbocharged gasoline engine. In fact, for the automotive industry the turbocharger appears to be the last remaining avenue to real, neck snapping performance. Additionally, it may well be the only way the world’s automakers have to provide the fuel economy values now necessary and still retain any motoring excitement. In the boating industry too, turbocharging has made its mark. But, it has been primarily for blood curdling, hair raising, brutally powerful engines that make fishermen curse, mothers grab their children in fear. and make Walter Mittys out of the most conservative family boaters. Well, this image may be in for some changes.

With engines from Detroit getting smaller the advantages of turbocharging production engines becomes very enticing. In the early stages of company development at Gale Banks Engineering the backbone of production was chrome glistening, custom high horsepower applications. Last year Banks broke stride in introducing a bolt-on turbo kit for the MerCruiser package. Sales have been marvelous according to Banks.

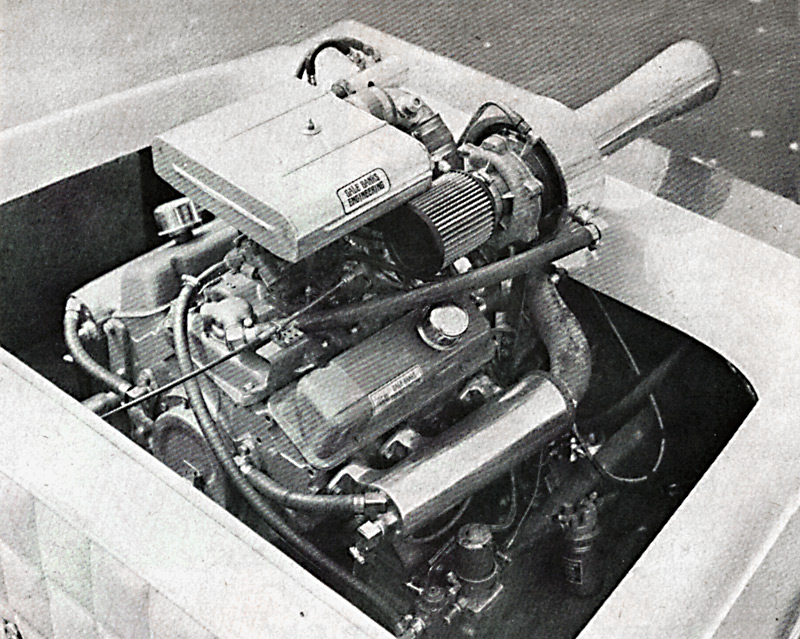

While shifting his emphasis from speed to economy Banks has quietly been doing research and development on Chevrolet’s new V-6. To the best of our knowledge these engines will not be available for marine use until Winter 1979 and Banks is one of the few spending time and money to develop the engine. Realizing that many of the turbo system components are patent pending Banks gave PB an exclusive to test his hardware of the future.

Before we get into a technical look at Gale Banks Engineering’s single-turbo V-6 project, a number of points must be made clear. The hardware pictured and described in this article is strictly research and development equipment. When it does eventually go into production in all likelihood it will bear only vague resemblance to its present configuration. It is being presented here to give our readers a rough idea of what goes into the development of a totally new power package, and hopefully to provide a glimpse at a probable future approach to performance, economy and compactness yet to be available for the powerboating enthusiast.

THE ENGINE

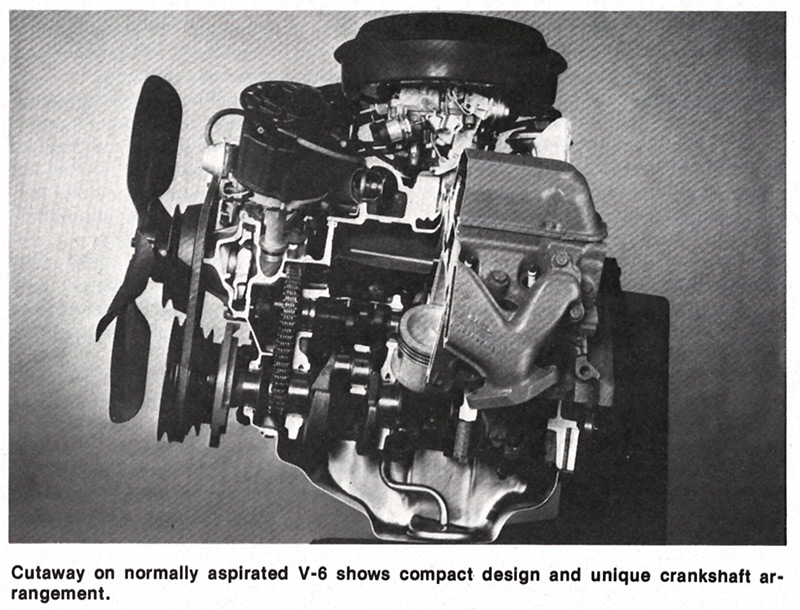

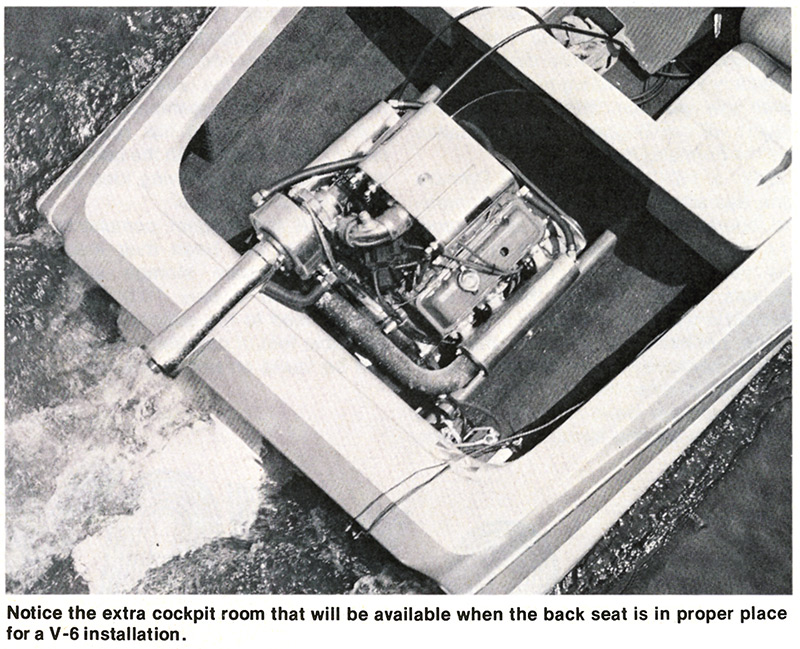

Before we look at the turbo/system, let’s take a look at Chevy’s new 90º V-6. The first question that comes to mind is, “Why a cast iron V-6?” When you look at Chevrolet’s rationale for making this their engine of the future, you realize that most of the criteria that led them into production of the V-6, also holds true for boating applications. The first objectives are compact envelope size and light weight. Obviously, the V-6 enjoys significant compactness relative to the V-8’s from which it was partially derived, by virtue of elimination of two of its cylinders. Roughly speaking, this reduces its length to three quarters the length of the small block Chevrolet V-8, which itself is a notably compact engine. Banks feels that this reduction in engine size is very valuable for future boating applications, as it allows the use of a smaller hull for a given amount of interior space. This, of course, will translate into lighter weight, better performance, and better fuel mileage, while still providing the same passenger accommodations as a fractionally larger hull. Secondary benefits will also include improved trailer· ability and improved mileage while towing. Finally, a reduction in overall length, in many instances, may make the difference between storing the family ski-boat in the garage or in the driveway … an important factor indeed.

So, the V-6 looks good from a compactness standpoint, and a compact engine is also a light engine, but why cast iron? First, a short, wide crankcase like that of the V-6 is inherently rigid. This basic rigidity allows the use of less cast iron to achieve an engine framework which is still capable of providing adequate structural integrity for integra· lion of other engine elements. Thus, the V·6 is lighter than it might at first appear. However, the crux of the decision to use cast iron was cost. Unlike an aluminum engine, a cast iron engine requires no insert valve guides, no insert valve seats, no special cylinder liners, no steel thread inserts, etc. Therefore, it costs less to produce and ultimately costs the end user less.

Next, why a 90º V-6 instead of a 60º V-6 which is inherently easier to make smoother running? Again, the answer is cost. The 90º V-6 has basic dimensions, which are common with the small block Chevrolet V-8. This means that it can be produced at Chevrolet facilities, which are now producing V-8s. Not having to develop new, multi-million dollar production facilities saves non-recurring production costs, which would otherwise have to be amortized over an anticipated number of engines to be produced.

Result? Again, lower production costs with lower cost to the end user.

Finally, how did Chevy get around the inherent imbalance problems associated with a 90º V-6? They did it through the use of paired, offset crankpins between each pair of main bearings. Thus, the engine’s four-main-bearing crankshaft actually utilizes six discreet connecting rod journals to more uniformly distribute cylinder firing impulses which would otherwise be quite non-uniform. Consequently, overall operation is every bit as smooth as a more conventional six cylinder engine.

As a final added bonus, because the 90º Chevrolet V-6 was derived from the popular family of small-block Chevy V-8s, many engine elements are exactly the same. Thus, considerable aftermarket performance equipment already exists for this stubby little brother to the Chevy “mouse motor.”

THE TURBO SYSTEM

Next, let’s look at the status of Bank’s single-turbo V-6 R & D project. By the end of the development segment of this program, Gale hopes to provide a propulsion package, which accomplishes the following objectives:

1. Absolute minimum weight for optimum boating and towing economy.

2. Minimal intrusion of the propulsion package into the boat’s interior, thus allowing a smaller hull to be used with· out sacrificing space needed to comfortably accommodate passengers.

3. Reduced exhaust and noise emissions.

4. Maximum simplicity for tow maintenance and competitive propulsion package cost.

5. Turbo system and fuel metering technology, which drastically extend fuel mileage.

6. Acceleration and speed greater than that provided by the current generation of stock, big block V-8 power plants.

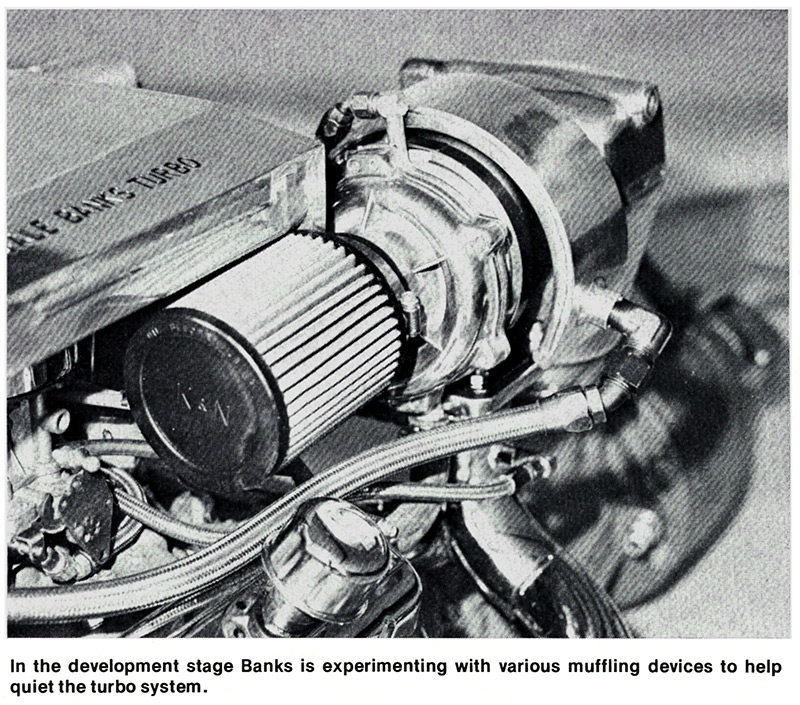

The engine’s turbo system consists of a pair of jacketed, cast aluminum exhaust manifolds which discharge toward the flywheel end of the engine. A fabricated steel collector bolts to the aft face of each exhaust manifold and directs exhaust gasses together and upward where it terminates into a horizontal mounting flange for the turbine inlet of a single turbocharger. At the present time, a Rajay model 301 E10 turbocharger is being tested which uses a 1.0 A/R turbine housing incorporating a bypass hole between the· turbine inlet and exducer, to keep intake boost in the desired general range. Exhaust from the turbine section of the turbocharger is then directed aft via a single O/T type exhaust stack.

On the intake side, air is drawn directly into the forward facing compressor inlet, compressed to about 6/10 atmosphere, and discharged into an aluminum plenum mounted atop a Holley, 350 CFM USCG approved two-barrel carburetor.

The carburetor’s hand fabricated aluminum intake plenum is fitted internally with a USCG approved flame arrestor element. Additional safety protection is provided by lines which run from the plenum area to the carburetor’s butterfly-shaft bearing lugs. This pressurizes the butterfly shaft bearings to contain any gasoline or fuel vapors which would otherwise be blown out the bearing clearances by intake boost pressure.

Although this arrangement constitutes a “blow-through” system, a “draw-through” variation is also slated for testing, wherein the carburetor will be located upstream of the turbocharger compressor inlet. Additionally, two fuel-injected variations are also scheduled for subsequent testing. Both arrangements will utilize an electronically modulated fuel injector in lieu of the carburetor. Constant-flow and intermittent-flow injectors will both be tested to evaluate potential performance benefits. The existing system, as pictured in this article and tested by Powerboat, produces about 240 h.p. at 4800 rpm.

THE PERFORMANCE

Okay, so what’s it like to drive this 16 footer powered with this little sawed-off three-quarter brother to a V-8? Not too shabby at all. Although noisier than production units will be, it’s still noticeably quieter than a big V-8 powered boat with O/T pipes. Even without adjustable trim, it gets on top surprisingly quick, which is probably a result of the light drive-system weight. Power, torque, and boost rise are amazingly smooth, with no noticeable sensation of the turbo “cutting in.” Off idle acceleration is slightly quicker than a 454 or 460 V-8 powered 17 or 18 footer, with top speed about the same at 59 mph and 4000 rpm. Two-way average acceleration times from 0-30 mph and 0-50 mph were 3.6 and 8.4 seconds respectively. Not bad at all!

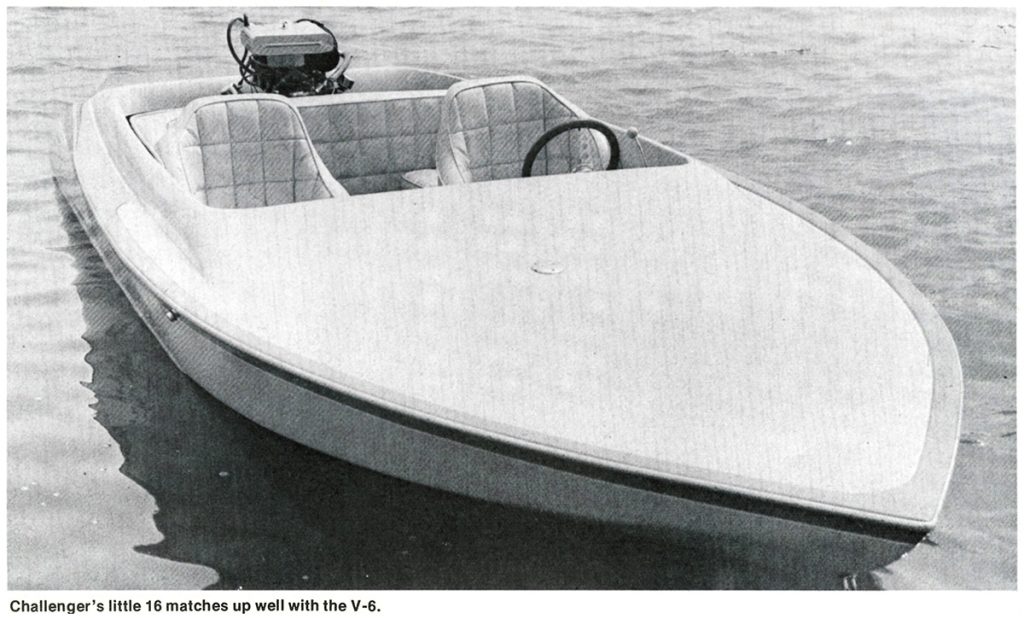

The slightly diminutive Challenger hull was very pleasant to drive. It came onplane quickly, turned equally well at low and high speeds, and rode very dry if not a little bow-down. Gale feels that jet nozzle angle adjustments will easily cure the slight bow-in ride, with a corresponding decrease in hull wetted area. Furthermore, moving the rear seat back to take full advantage of the engine’s short length would provide plenty of interior space for four adults plus skis and other paraphernalia.

The Challenger hull used to test the V-6 was designed nearly a decade ago in 1969 by Dick Patterson and Bill Zinser. The hull never reached its potential because 16 foot performance boats never took off in the marketplace. In fact, Challenger hasn’t sold one of these babies in three years and even back then, production was very, very limited.

Originally, the boat was built with a firm riding eight degrees bottom. During the last energy scare in 1974 Challenger pulled the boat out of mothballs while revamping the hull to sport a softer riding 15 degrees bottom with four lifting strakes.

Early powerplant options for the 16 consisted of either top-of-the-line horsepower from Chevrolet or Oldsmobile. With a hull weight of 600 pounds the big rat Chevrolets were just too much muscle. It took 10 years to perfectly match this soundly designed boat to the ideal powerplant and Challenger is dusting off their molds in anticipation of the late winter arrival of the V-6 Chevrolet.

Due to its envelope size the turbocharged Chevrolet V-6 makes a 16 foot hull like the Challenger have as much, or more, interior space than most ski boats two or three feet longer. In our test boat the fuel tank was mounted in the bow of the boat and although it didn’t create havoc with the performance like we expected, the hull would perform even better with additional fine tuning of weight placement. If interest develops in the package as expected, Challenger plans on making a fuel tank relocation along with several other modifications.

A discussion on the boats performance wouldn’t be complete without reporting on how well the engine/boat matched up to the propulsion system. As near as we can tell the turbocharged Chevrolet V-6 will be the jet boat engine of the future. Banks is definitely not ruling out the possibilities for the engine in either stern drive or V-driven boats, however, he’s quite confident that this elaborate project will grab hold in the pump end of the industry.

“There has been a trend recently toward the stern drive as an efficient propulsion device … and it is efficient,” says Banks. “However, the jet drive has never quite had an equal chance to prove itself. While every drive system has its strong points, the jet pump has a number of undeniable attributes possessed by no other drive type. These include the best possible shallow water operation, minimal encroachment of the boats interior space and low maintenance costs.”

Performance figures on the jet test boat were excellent and Banks contends that the future is even brighter. In the mill are several changes in the jet unit itself. Given time, we’ll probably see an economy jet drive model, matched to these smaller engines and hulls, that should increase top speed several miles per hour while also tightening up sensitive fuel economy figures.

FUEL ECONOMY

The most talked about topic these days … and in the future. Although they have put up a fight of sorts to combat the myth that jet boats are energy guzzlers, it’s no secret that fuel economy has been a severe bend in the jet boat industries flow. In some instances jets were indeed heavy consumers but the defense that the blame lies more in the situations they are used in than with any shortcomings of the propulsion system itself is true.

After testing the turbocharged V-6 Challenger for several hours we were definitely convinced of one thing … if this is the jet mill of the future, fuel economy is going to be a big sales point not a scoffed-at item. Even in a somewhat rough prototype stage the fuel economy benefits leap out on the data page. At 25 mph the V-6 needed but 4.0 gph which is almost half of what a similar designed 18 foot jet equipped with a 325 horsepower V-8 could muster. Moving the speedometer up to 35 mph produced a reading in the mid 5 gph range, once again almost half of what is expected from a typical jet installation. On the top end things really get interesting.

When we first attached our test fuel meter the readings at full bore were right at 11 gph which is no disgrace when compared to any drive system in a boat of equivalent size and top end speed. How· ever, it should be noted that Banks, through further refinement has seen numbers as low as 8 gph under full load We anticipated that the fuel consumption on the V-6 midget would be good but no one thought numbers like these would show up so soon in the development stage.

AND IN THE END

AND IN THE END

If we had to select one word in describing the Challenger turbocharged V-6 it would be outstanding. Like most everyone in the performance boating industry we weren’t too excited about the prospects of enticing first time buyers to the sport considering rising fuel costs, smaller powerplants and pee-wee tow vehicles. However, dyed in the wool performance buffs will never die … they only change to adapt to the times.

More than two years ago Banks went out on the limb saying he could make a 16 foot boat have as much room and per· form on par with current 18 foot/454 normally aspirated jet boats that have been popular the last several years. Using a mildly turbocharged prototype Chevrolet V-6 the Challenger 16 footer was on plane with anything we’ve ever driven in “ski boat” low profile size, no matter what the drive system. Fuel economy was superb, remembering that we were driving a craft capable of near 60 mph, not last years fishing rig.

So what does all this fancy R & D boil down to in the final analysis? Well, it really depends upon your perspective. Looking at it with respect to the immediate future, like tomorrow, next week or even later this summer, it’s really no big deal. You can’t go out and buy a turbo V-6 powered boat now and you probably wouldn’t really want to anyway. But looking a little farther down the line, as the existing family water-ski machine starts getting tired, and gas prices climb even higher, it would certainly be nice to be able to weigh the advantages of a miserly little V-6 buzz bomb against the standard V-8, when contemplating the family’s next boat purchase. Gale Banks thinks so, and we suspect many others will agree.

So! Don’t run out and deep six your existing V-8 marine engine. And don’t worry about a drastic fuel shortage relegating your boat to a giant fiberglass planter box, either. Recreational boating is here to stay, in one form or another. We just think that econo wizard Gale Banks, and his turbo V-6 performance odyssey, may well contribute a legitimate preview of what the future performance boating holds in store for us.

Click here for a PDF of this article »